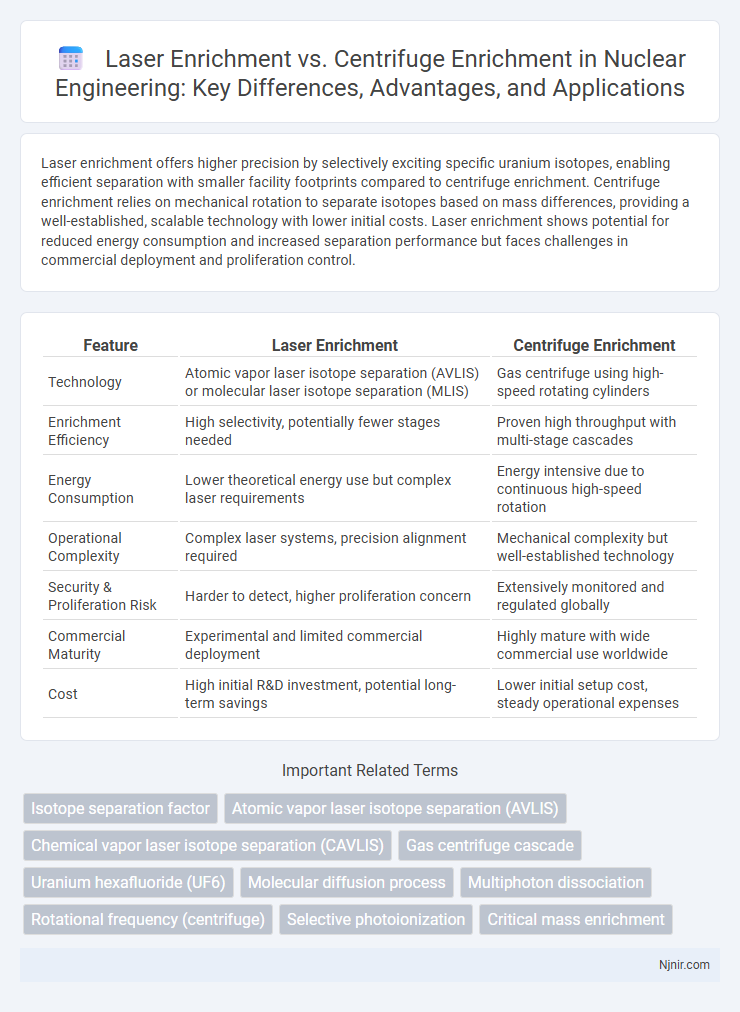

Laser enrichment offers higher precision by selectively exciting specific uranium isotopes, enabling efficient separation with smaller facility footprints compared to centrifuge enrichment. Centrifuge enrichment relies on mechanical rotation to separate isotopes based on mass differences, providing a well-established, scalable technology with lower initial costs. Laser enrichment shows potential for reduced energy consumption and increased separation performance but faces challenges in commercial deployment and proliferation control.

Table of Comparison

| Feature | Laser Enrichment | Centrifuge Enrichment |

|---|---|---|

| Technology | Atomic vapor laser isotope separation (AVLIS) or molecular laser isotope separation (MLIS) | Gas centrifuge using high-speed rotating cylinders |

| Enrichment Efficiency | High selectivity, potentially fewer stages needed | Proven high throughput with multi-stage cascades |

| Energy Consumption | Lower theoretical energy use but complex laser requirements | Energy intensive due to continuous high-speed rotation |

| Operational Complexity | Complex laser systems, precision alignment required | Mechanical complexity but well-established technology |

| Security & Proliferation Risk | Harder to detect, higher proliferation concern | Extensively monitored and regulated globally |

| Commercial Maturity | Experimental and limited commercial deployment | Highly mature with wide commercial use worldwide |

| Cost | High initial R&D investment, potential long-term savings | Lower initial setup cost, steady operational expenses |

Introduction to Uranium Enrichment Methods

Laser enrichment and centrifuge enrichment are two advanced uranium enrichment methods used to increase the concentration of U-235 isotopes in nuclear fuel. Laser enrichment utilizes selective excitation of uranium isotopes with precise laser wavelengths, allowing high separation efficiency and lower energy consumption compared to traditional techniques. Gas centrifuge enrichment relies on high-speed rotational forces to separate isotopes based on mass differences, offering proven scalability and widespread adoption in the nuclear industry.

Fundamentals of Laser Enrichment Technology

Laser enrichment technology utilizes the precise excitation of uranium isotopes through tuned laser frequencies, enabling selective ionization and separation of uranium-235 from uranium-238 with high isotopic purity. This process leverages atomic vapor lasers to target specific electron transitions, offering increased efficiency and lower energy consumption compared to centrifuge enrichment, which relies on high-speed rotation and centrifugal force to separate isotopes based on mass differences. The fundamental advantage of laser enrichment lies in its ability to achieve rapid, isotope-selective ionization without mechanical components, potentially reducing operational complexity and enhancing scalability.

Overview of Centrifuge Enrichment Processes

Centrifuge enrichment processes use high-speed rotating cylinders to separate uranium isotopes based on mass differences, offering higher efficiency and lower energy consumption compared to gaseous diffusion methods. These processes achieve enrichment by exploiting the slight mass variance between uranium-235 and uranium-238, enabling effective separation within cascades of centrifuges. Centrifuge technology plays a crucial role in global uranium enrichment, underpinning both civilian nuclear power generation and naval propulsion systems.

Efficiency Comparison: Laser vs. Centrifuge Techniques

Laser enrichment techniques offer higher precision and selectivity in isotope separation, resulting in greater efficiency compared to centrifuge enrichment methods. While centrifuges rely on rapid rotation to separate isotopes based on mass differences, laser enrichment uses tuned photons to selectively ionize specific isotopes, significantly reducing energy consumption and material waste. This targeted approach enables laser enrichment to achieve higher separation factors and lower operational costs in uranium enrichment processes.

Energy Consumption and Operational Costs

Laser enrichment technology consumes significantly less energy compared to centrifuge enrichment due to its higher separation efficiency and lower mechanical demands. Operational costs for laser enrichment can be lower since it requires fewer stages and less maintenance than centrifuge systems, which rely on extensive rotating machinery. However, laser enrichment facilities face higher initial capital expenses due to complex laser equipment and stringent safety requirements.

Proliferation Risks and Security Considerations

Laser enrichment technology presents distinct proliferation risks compared to centrifuge enrichment due to its ability to be more easily concealed and its lower energy signature, complicating detection by international monitoring agencies. Centrifuge enrichment facilities are generally larger and more complex, making them more vulnerable to surveillance but also raising concerns over the rapid production of highly enriched uranium if cascades are expanded illicitly. Security considerations emphasize stringent monitoring and verification protocols, with laser enrichment requiring enhanced detection techniques to prevent clandestine nuclear weapon material production.

Plant Infrastructure and Scalability

Laser enrichment technology requires a complex laser system and advanced optical components, demanding precise environmental control and sophisticated plant infrastructure, which can lead to higher upfront capital costs but allows for more compact facility designs. Centrifuge enrichment relies on rotating centrifuges housed within extensive cascade arrangements, necessitating larger physical plant footprints and robust mechanical systems, but offers proven scalability with modular unit additions to increase capacity. The scalability of laser enrichment is potentially faster due to reduced physical space needs and automation, whereas centrifuge enrichment benefits from established industrial processes and ease of incremental capacity expansion.

Environmental Impacts and Waste Generation

Laser enrichment produces significantly less nuclear waste compared to centrifuge enrichment due to its higher efficiency in uranium isotope separation, resulting in reduced tailings. The process also consumes less energy, minimizing greenhouse gas emissions associated with uranium enrichment. Centrifuge enrichment generates more depleted uranium waste and requires higher energy inputs, leading to greater environmental impacts overall.

Current Applications and Commercial Viability

Laser enrichment technology offers precise isotope separation with high efficiency, primarily used in limited commercial settings due to its complex infrastructure and high operational costs. Centrifuge enrichment, by contrast, dominates the global market because of its proven scalability, lower energy consumption, and established supply chains supporting nuclear power generation. Current commercial viability favors centrifuge methods, while laser enrichment remains in experimental and niche applications with potential future expansion.

Future Prospects in Enrichment Technology

Laser enrichment technology offers higher efficiency and precision by selectively targeting uranium isotopes, potentially reducing energy consumption and waste compared to centrifuge enrichment. Advances in laser systems, such as atomic vapor laser isotope separation (AVLIS) and molecular laser isotope separation (MLIS), promise greater scalability and lower operational costs. Continued research and development in laser enrichment could revolutionize nuclear fuel production by enabling more compact, versatile, and environmentally friendly enrichment facilities in the future.

Isotope separation factor

Laser enrichment achieves a higher isotope separation factor than centrifuge enrichment by selectively exciting specific isotopes with tailored laser frequencies.

Atomic vapor laser isotope separation (AVLIS)

Atomic Vapor Laser Isotope Separation (AVLIS) enriches uranium by selectively ionizing specific isotopes using tuned lasers for high precision, offering greater enrichment efficiency and lower energy consumption compared to traditional centrifuge methods.

Chemical vapor laser isotope separation (CAVLIS)

Chemical Vapor Laser Isotope Separation (CAVLIS) achieves higher uranium-235 enrichment efficiency and selectivity compared to centrifuge enrichment by using tunable lasers to selectively ionize isotopes in vaporized uranium compounds.

Gas centrifuge cascade

Gas centrifuge cascades achieve higher uranium enrichment efficiency and lower energy consumption compared to laser enrichment methods due to their advanced separation mechanics and scalability.

Uranium hexafluoride (UF6)

Laser enrichment achieves higher separation efficiency of Uranium hexafluoride (UF6) isotopes compared to centrifuge enrichment by selectively exciting specific isotopes using precise laser wavelengths.

Molecular diffusion process

Laser enrichment enhances uranium isotope separation by selectively exciting specific isotopes using photon absorption, while centrifuge enrichment relies on molecular diffusion driven by centrifugal force to separate isotopes based on mass differences.

Multiphoton dissociation

Multiphoton dissociation in laser enrichment enables highly selective isotope separation by using precise photon energy to dissociate targeted isotopes, offering greater efficiency and selectivity compared to centrifuge enrichment's mechanical isotope separation process.

Rotational frequency (centrifuge)

Centrifuge enrichment relies on high rotational frequencies typically ranging from 50,000 to 100,000 revolutions per minute to effectively separate uranium isotopes, whereas laser enrichment uses precise photon wavelengths without mechanical rotation.

Selective photoionization

Selective photoionization in laser enrichment enables precise isotope separation by ionizing specific isotopes with tailored laser frequencies, offering higher enrichment efficiency compared to centrifuge enrichment's mechanical isotope separation.

Critical mass enrichment

Laser enrichment achieves higher critical mass enrichment levels faster and with greater precision than centrifuge enrichment by selectively targeting uranium isotopes at the atomic level.

laser enrichment vs centrifuge enrichment Infographic

njnir.com

njnir.com