High-assay low-enriched uranium (HALEU) contains a higher concentration of the uranium-235 isotope, typically between 5% and 20%, compared to low-enriched uranium (LEU), which is enriched below 5%. HALEU offers enhanced fuel performance, increased reactor efficiency, and improved fuel cycle economics, making it suitable for advanced nuclear reactors and small modular reactors (SMRs). The use of HALEU supports extended fuel life and higher burnup rates, contributing to reduced nuclear waste generation and optimized energy output.

Table of Comparison

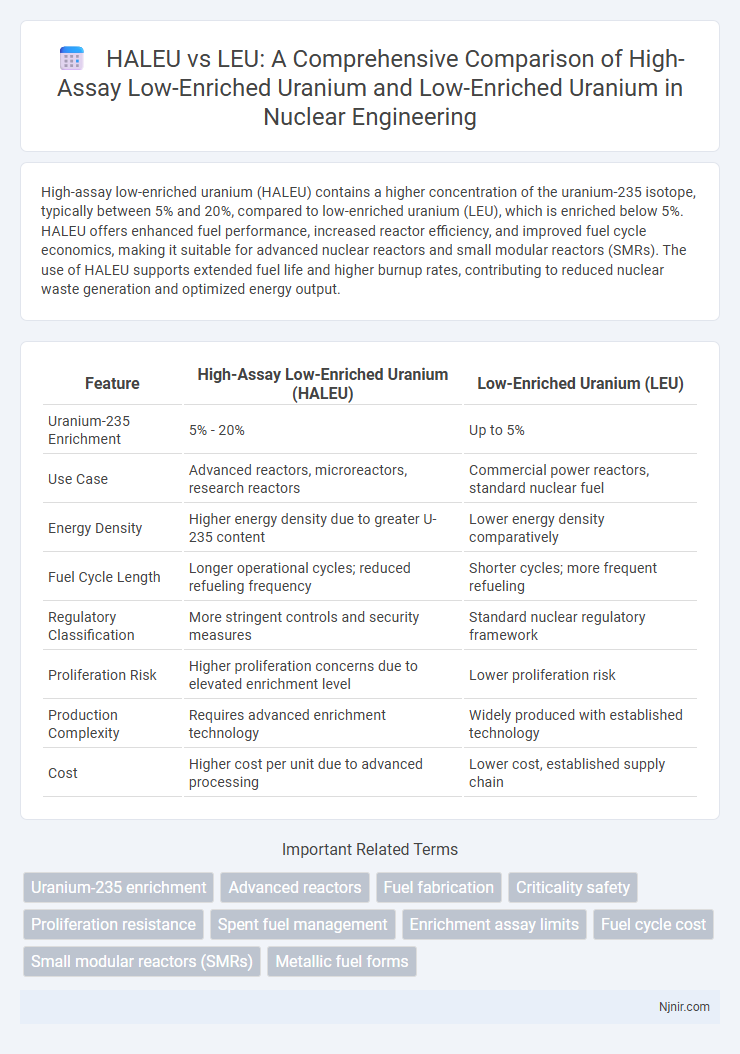

| Feature | High-Assay Low-Enriched Uranium (HALEU) | Low-Enriched Uranium (LEU) |

|---|---|---|

| Uranium-235 Enrichment | 5% - 20% | Up to 5% |

| Use Case | Advanced reactors, microreactors, research reactors | Commercial power reactors, standard nuclear fuel |

| Energy Density | Higher energy density due to greater U-235 content | Lower energy density comparatively |

| Fuel Cycle Length | Longer operational cycles; reduced refueling frequency | Shorter cycles; more frequent refueling |

| Regulatory Classification | More stringent controls and security measures | Standard nuclear regulatory framework |

| Proliferation Risk | Higher proliferation concerns due to elevated enrichment level | Lower proliferation risk |

| Production Complexity | Requires advanced enrichment technology | Widely produced with established technology |

| Cost | Higher cost per unit due to advanced processing | Lower cost, established supply chain |

Introduction to Uranium Enrichment Levels

High-assay low-enriched uranium (HALEU) contains uranium-235 enriched between 5% and 20%, offering higher energy density than conventional low-enriched uranium (LEU), which is enriched below 5%. HALEU enables improved fuel performance and efficiency in advanced nuclear reactors, including small modular reactors (SMRs) and research reactors. The enrichment level significantly impacts reactor design, fuel cycle length, and proliferation risk, making HALEU a strategic material for next-generation nuclear technologies.

Defining HALEU and LEU: Key Differences

High-assay low-enriched uranium (HALEU) contains uranium-235 enriched between 5% and 20%, offering higher energy density compared to low-enriched uranium (LEU), which has uranium-235 concentrations below 5%. HALEU's increased enrichment enables advanced nuclear reactors to achieve greater efficiency and longer fuel cycles, while LEU is widely used in conventional nuclear power plants and research reactors. The elevated fissile content in HALEU presents both enhanced performance potential and regulatory challenges distinct from the well-established LEU industry standards.

Production Methods for HALEU and LEU

High-assay low-enriched uranium (HALEU) is produced through advanced uranium enrichment techniques, primarily gas centrifuge and the emerging aerodynamic and laser isotope separation methods, achieving enrichment levels between 5% and 20% U-235, unlike traditional low-enriched uranium (LEU) which typically ranges from 3% to 5% U-235 and is mainly produced via gas centrifuge and gaseous diffusion. HALEU production demands higher assay precision and improved cascade configurations to efficiently increase U-235 concentration while minimizing tails assay. Innovative enrichment technologies and process optimizations are essential for scaling HALEU production to support advanced reactors and high-performance nuclear fuel applications.

Applications in Nuclear Reactors

High-assay low-enriched uranium (HALEU) and low-enriched uranium (LEU) differ primarily in uranium-235 concentration, with HALEU enriched between 5% and 20%, while LEU is below 5%. HALEU's higher enrichment enables advanced reactors, such as small modular reactors (SMRs) and fast reactors, to operate more efficiently and achieve longer fuel cycles compared to traditional reactors using LEU. LEU remains widely used in currently operational light water reactors (LWRs), supporting established nuclear power generation with proven fuel technology.

Safety and Handling Considerations

High-assay low-enriched uranium (HALEU) contains uranium-235 enriched between 5% and 20%, requiring stricter safety protocols due to its higher radiological and criticality risks compared to traditional low-enriched uranium (LEU), which is enriched below 5%. HALEU demands enhanced containment measures, specialized transport regulations, and rigorous monitoring to mitigate increased potential for nuclear criticality and radiation exposure during handling. The adoption of HALEU necessitates updated licensing frameworks and operator training to ensure safe management across fuel fabrication, storage, and irradiation processes.

Regulatory and Nonproliferation Implications

High-assay low-enriched uranium (HALEU), enriched between 5% and 20% U-235, presents distinct regulatory challenges compared to conventional low-enriched uranium (LEU) with enrichment below 5%, necessitating enhanced safeguards and licensing protocols due to its higher proliferation risk. Regulatory bodies such as the Nuclear Regulatory Commission (NRC) impose stringent security measures and transportation controls on HALEU to prevent diversion for illicit weapons use. The nonproliferation implications are significant, as the elevated enrichment level of HALEU bridges the gap toward weapons-grade uranium, increasing the necessity for robust international monitoring and transparency frameworks under the Treaty on the Non-Proliferation of Nuclear Weapons (NPT).

Supply Chain and Availability

High-assay low-enriched uranium (HALEU) offers enhanced fuel performance for advanced reactors but faces significant supply chain challenges due to limited enrichment facilities capable of producing uranium enriched between 5% and 20% U-235. Low-enriched uranium (LEU), enriched below 5% U-235, benefits from an established global supply chain with widespread enrichment capacity and customs infrastructure, ensuring consistent availability for conventional nuclear reactors. Current efforts to expand HALEU availability focus on upgrading uranium enrichment plants, securing regulatory approvals, and developing dedicated fabrication facilities to meet growing demand from advanced nuclear technologies.

Economic Impact and Cost Considerations

High-assay low-enriched uranium (HALEU) offers higher energy density than traditional low-enriched uranium (LEU), reducing fuel consumption and operational costs in advanced reactors. Though HALEU production incurs higher upfront enrichment expenses compared to LEU, its enhanced efficiency can lower overall fuel cycle costs and improve economic competitiveness. Investment in HALEU infrastructure supports long-term cost savings by enabling extended fuel life and reducing waste management expenses relative to LEU-based systems.

Future Trends in Uranium Fuel Technology

High-assay low-enriched uranium (HALEU) with enrichment levels between 5% and 20% U-235 enables advanced reactor designs to achieve higher efficiency and longer fuel cycles compared to traditional low-enriched uranium (LEU) below 5%. Future trends in uranium fuel technology emphasize the development of HALEU to support small modular reactors (SMRs) and microreactors, enhancing proliferation resistance and reducing nuclear waste. Increasing investments in HALEU production infrastructure aim to meet the growing demand driven by next-generation nuclear power systems targeting carbon-neutral energy goals.

Challenges and Opportunities for HALEU and LEU

High-assay low-enriched uranium (HALEU) presents significant opportunities for advanced nuclear reactors due to its higher enrichment level (5-20% U-235) compared to traditional low-enriched uranium (LEU) under 5%, enabling improved fuel efficiency and reactor performance. Challenges for HALEU include limited proliferation resistance, complex supply chain development, and regulatory hurdles, whereas LEU benefits from established infrastructure and broad regulatory acceptance but faces limitations in supporting emerging reactor designs demanding higher enrichment. Optimizing the transition from LEU to HALEU necessitates investment in enrichment technology, fuel fabrication facilities, and international collaboration to ensure a secure, scalable, and economically viable nuclear fuel cycle.

Uranium-235 enrichment

High-assay low-enriched uranium (HALEU) contains uranium-235 enriched between 5% and 20%, offering higher energy density and improved reactor performance compared to standard low-enriched uranium (LEU) with uranium-235 enrichment below 5%.

Advanced reactors

High-assay low-enriched uranium (HALEU) with uranium-235 concentrations of 5-20% enhances advanced reactor efficiency and fuel performance compared to conventional low-enriched uranium (LEU) limited to below 5% uranium-235.

Fuel fabrication

High-assay low-enriched uranium (HALEU) requires specialized fuel fabrication processes with enhanced precision and safety measures compared to low-enriched uranium (LEU) due to its higher uranium-235 concentration of 5-20%, enabling advanced reactor performance but necessitating stricter handling and machining protocols.

Criticality safety

High-assay low-enriched uranium (HALEU) poses greater criticality safety challenges than low-enriched uranium (LEU) due to its higher U-235 concentration, requiring enhanced neutron moderation controls and stricter handling protocols to prevent unintended chain reactions.

Proliferation resistance

High-assay low-enriched uranium (HALEU) exhibits lower proliferation resistance than traditional low-enriched uranium (LEU) due to its higher U-235 concentration, which approaches weapons-grade material thresholds and requires more stringent safeguards to prevent diversion for nuclear weapons.

Spent fuel management

High-assay low-enriched uranium (HALEU) spent fuel requires more advanced management techniques than low-enriched uranium (LEU) due to its higher radioactivity, increased heat generation, and greater proliferation risk, necessitating specialized storage, transportation, and disposal protocols to ensure safety and environmental protection.

Enrichment assay limits

High-assay low-enriched uranium (HALEU) contains uranium-235 enriched between 5% and 20%, significantly higher than low-enriched uranium (LEU), which is enriched up to 5% uranium-235.

Fuel cycle cost

High-assay low-enriched uranium (HALEU) reduces fuel cycle costs compared to low-enriched uranium (LEU) by enabling higher burnup rates and longer fuel lifetimes, thereby decreasing refueling frequency and overall fuel management expenses.

Small modular reactors (SMRs)

High-assay low-enriched uranium (HALEU) enhances Small Modular Reactor (SMR) performance by offering higher energy density and improved fuel efficiency compared to traditional low-enriched uranium (LEU).

Metallic fuel forms

High-assay low-enriched uranium (HALEU) metallic fuels offer higher uranium density and improved neutron economy compared to traditional low-enriched uranium (LEU) metallic fuels, enabling enhanced reactor performance and extended fuel cycles.

high-assay low-enriched uranium (HALEU) vs low-enriched uranium (LEU) Infographic

njnir.com

njnir.com