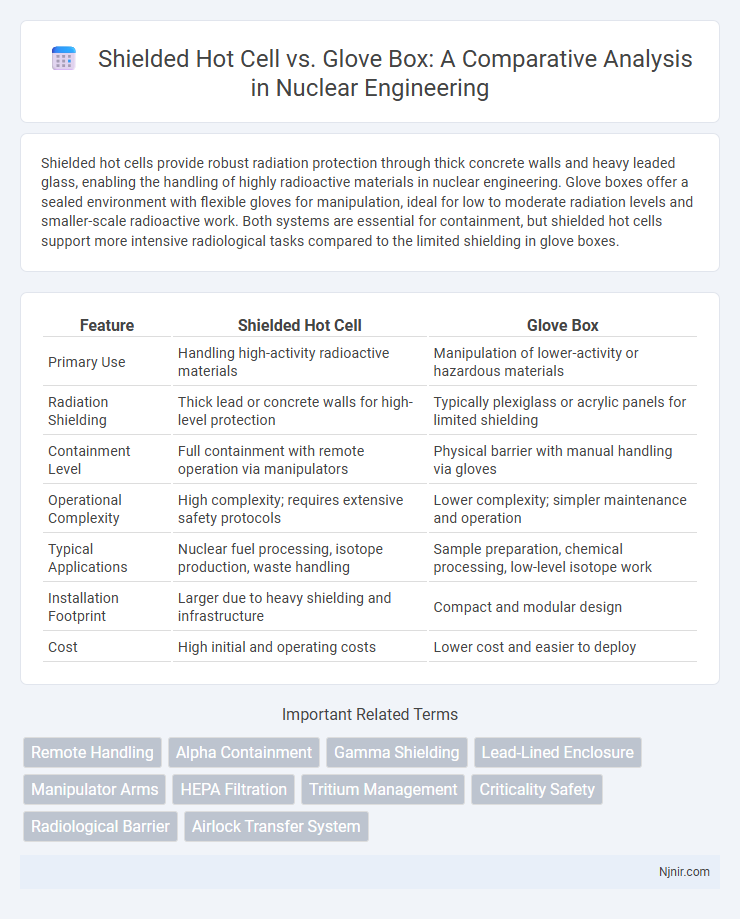

Shielded hot cells provide robust radiation protection through thick concrete walls and heavy leaded glass, enabling the handling of highly radioactive materials in nuclear engineering. Glove boxes offer a sealed environment with flexible gloves for manipulation, ideal for low to moderate radiation levels and smaller-scale radioactive work. Both systems are essential for containment, but shielded hot cells support more intensive radiological tasks compared to the limited shielding in glove boxes.

Table of Comparison

| Feature | Shielded Hot Cell | Glove Box |

|---|---|---|

| Primary Use | Handling high-activity radioactive materials | Manipulation of lower-activity or hazardous materials |

| Radiation Shielding | Thick lead or concrete walls for high-level protection | Typically plexiglass or acrylic panels for limited shielding |

| Containment Level | Full containment with remote operation via manipulators | Physical barrier with manual handling via gloves |

| Operational Complexity | High complexity; requires extensive safety protocols | Lower complexity; simpler maintenance and operation |

| Typical Applications | Nuclear fuel processing, isotope production, waste handling | Sample preparation, chemical processing, low-level isotope work |

| Installation Footprint | Larger due to heavy shielding and infrastructure | Compact and modular design |

| Cost | High initial and operating costs | Lower cost and easier to deploy |

Introduction to Shielded Hot Cells and Glove Boxes

Shielded hot cells and glove boxes are essential containment systems used in handling radioactive or hazardous materials, providing protection to operators and the environment. Shielded hot cells typically incorporate thick lead or concrete walls with remote manipulators, allowing safe handling of high-level radioactive substances. Glove boxes are sealed enclosures with built-in gloves, designed for lower-level contamination tasks requiring direct manual manipulation within an inert or controlled atmosphere.

Core Design Principles and Construction

Shielded Hot Cells are heavily shielded enclosures designed to handle highly radioactive materials, featuring thick lead or concrete walls and remote manipulators for safe operation. Glove Boxes, on the other hand, are sealed containers with built-in gloves allowing manual handling of hazardous substances in a controlled atmosphere, emphasizing ease of use and containment over radiation protection. Core design principles of Hot Cells prioritize radiation shielding, remote operation, and durability, whereas Glove Boxes focus on airtightness, operator dexterity, and maintaining inert or controlled gas environments.

Radiation Protection Capabilities

Shielded Hot Cells provide superior radiation protection through dense concrete and lead shielding, effectively containing high-level radioactive materials and gamma radiation emissions. Glove Boxes, typically constructed from thick acrylic or polycarbonate, offer limited protection suitable for low to moderate radiation levels and primarily safeguard against particulate contamination. For handling isotopes emitting intense gamma or neutron radiation, Shielded Hot Cells ensure enhanced operator safety and environmental containment compared to the less robust shielding of Glove Boxes.

Operational Safety and Containment Features

Shielded hot cells provide robust radiation protection through heavy lead and concrete shielding, enabling safe handling of highly radioactive materials with remote manipulators, minimizing operator exposure. Glove boxes feature airtight, sealed chambers with built-in gloves, ensuring containment of hazardous substances while allowing direct manual manipulation, optimized for less radioactive or toxic materials. Both systems incorporate advanced filtration and ventilation to prevent contamination release, but hot cells excel in isolating high-level radioactive waste due to superior shielding and remote operation capabilities.

Typical Applications in Nuclear Engineering

Shielded hot cells are primarily used for the remote handling and examination of highly radioactive materials, including fuel rod inspection, reprocessing, and waste management in nuclear reactors. Glove boxes are suited for manipulating low to moderately radioactive substances in a controlled atmosphere, commonly applied in radioactive sample preparation, chemical synthesis, and contamination testing. Both systems ensure operator protection but differ in shielding thickness, with hot cells providing heavy shielding for high-level radiation environments and glove boxes offering sealed containment for less intense radiation scenarios.

Handling of Highly Radioactive Materials

Shielded Hot Cells provide robust gamma radiation shielding using thick concrete and leaded glass, enabling manipulation of highly radioactive materials with remote mechanical tools while ensuring operator safety. Glove Boxes offer a sealed environment with physical gloves attached to transparent panels, suitable for handling moderately radioactive or toxic substances but less effective against intense gamma radiation. For extreme radioactivity requiring stringent containment and radiation protection, Shielded Hot Cells are the preferred choice due to superior shielding and remote operation capabilities.

Maintenance and Decontamination Procedures

Maintenance of Shielded Hot Cells requires periodic inspection of lead glass windows, robotic manipulators, and ventilation systems to ensure radiation shielding and containment integrity, while Glove Boxes demand frequent glove replacement, leak testing, and filter changes to maintain airtight conditions. Decontamination procedures in Shielded Hot Cells involve remote-controlled cleaning tools and high-pressure washing systems designed to handle high radiation levels safely; Glove Boxes require manual cleaning with appropriate solvents and surface disinfectants, focusing on glove and interior surface decontamination to prevent contamination spread. Both systems emphasize strict adherence to contamination control protocols but differ in complexity and operational risks due to the variance in radiation exposure and containment methods.

Cost Comparison and Resource Requirements

Shielded Hot Cells typically incur higher initial capital costs due to robust radiation shielding, heavy-duty construction, and complex ventilation systems compared to Glove Boxes, which are generally more affordable with simpler containment designs. Operational expenses for Hot Cells rise because of ongoing maintenance of shielding materials and sophisticated remote handling equipment, whereas Glove Boxes demand fewer resources and lower maintenance costs. Resource requirements in Hot Cells include specialized personnel and extensive safety protocols, contrasting with Glove Boxes that require less specialized training and simpler infrastructure.

Regulatory Compliance and Industry Standards

Shielded Hot Cells and Glove Boxes must adhere to strict regulatory compliance standards such as NRC regulations and ISO 17873 for safe handling of radioactive materials. Shielded Hot Cells provide enhanced radiation protection through dense shielding and remote operation, meeting stringent industry standards for high-activity environments. Glove Boxes, used primarily for lower radiation levels, comply with OSHA and ANSI guidelines, ensuring containment and operator safety during manipulation of hazardous substances.

Criteria for Selecting Between Hot Cells and Glove Boxes

Criteria for selecting between shielded hot cells and glove boxes include radiation levels, containment requirements, and manipulation complexity. Hot cells provide high radiation shielding and allow remote handling of highly radioactive materials, making them suitable for operations involving intense radiation or large sources. Glove boxes, offering lower shielding but enhanced dexterity through direct manual manipulation, are preferred for less radioactive substances or tasks requiring fine motor skills.

Remote Handling

Shielded Hot Cells provide enhanced remote handling capabilities with robust radiation shielding and integrated manipulators, whereas Glove Boxes offer limited remote manipulation primarily through sealed gloves for less hazardous materials.

Alpha Containment

Shielded Hot Cells provide superior alpha containment with reinforced barriers and remote handling capabilities, while Glove Boxes offer limited alpha protection primarily suitable for lower-risk alpha-emitting materials.

Gamma Shielding

Shielded Hot Cells provide superior gamma radiation shielding using dense lead and concrete barriers compared to the thinner materials typically employed in Glove Boxes, making them more effective for handling high-activity radioactive sources.

Lead-Lined Enclosure

Shielded hot cells feature lead-lined enclosures designed for maximum radiation protection during manipulation of high-activity radioactive materials, whereas glove boxes typically use less extensive lead shielding for lower radiation applications.

Manipulator Arms

Manipulator arms in Shielded Hot Cells offer enhanced radiation protection and dexterity for handling highly radioactive materials compared to the more limited reach and shielding of glove boxes.

HEPA Filtration

Shielded Hot Cells and Glove Boxes both utilize HEPA filtration systems to maintain sterile environments, but Shielded Hot Cells require higher-capacity HEPA filters to manage increased radioactive particulate containment.

Tritium Management

Shielded Hot Cells provide enhanced radiation protection and containment for high-activity tritium handling compared to Glove Boxes, which offer easier accessibility but lower shielding, making Hot Cells preferable for advanced tritium management in nuclear and research applications.

Criticality Safety

Shielded Hot Cells provide superior criticality safety through robust radiation shielding and containment for handling high-activity nuclear materials compared to Glove Boxes, which offer limited protection mainly for low-activity or alpha-emitting substances.

Radiological Barrier

A Shielded Hot Cell provides a robust radiological barrier with heavy shielding and remote handling for high-radiation materials, whereas a Glove Box offers a lighter, transparent containment with glove ports for lower radiation levels and direct manual manipulation.

Airlock Transfer System

The Airlock Transfer System in Shielded Hot Cells ensures secure, contamination-free material handling through radiation-resistant barriers, whereas Glove Boxes utilize flexible gloves and sealed compartments for safe manipulation of hazardous substances without radiation shielding.

Shielded Hot Cell vs Glove Box Infographic

njnir.com

njnir.com