Pressurized Water Reactors (PWRs) maintain water under high pressure to prevent boiling, using a primary loop to transfer heat to a secondary loop that drives the turbines, enhancing safety by isolating the radioactive coolant. Boiling Water Reactors (BWRs) allow water to boil directly in the reactor core, producing steam that drives the turbines, simplifying the design but requiring more robust safety systems to manage radioactive steam. PWRs generally offer higher thermal efficiency and greater operational stability, while BWRs feature simpler designs and lower construction costs.

Table of Comparison

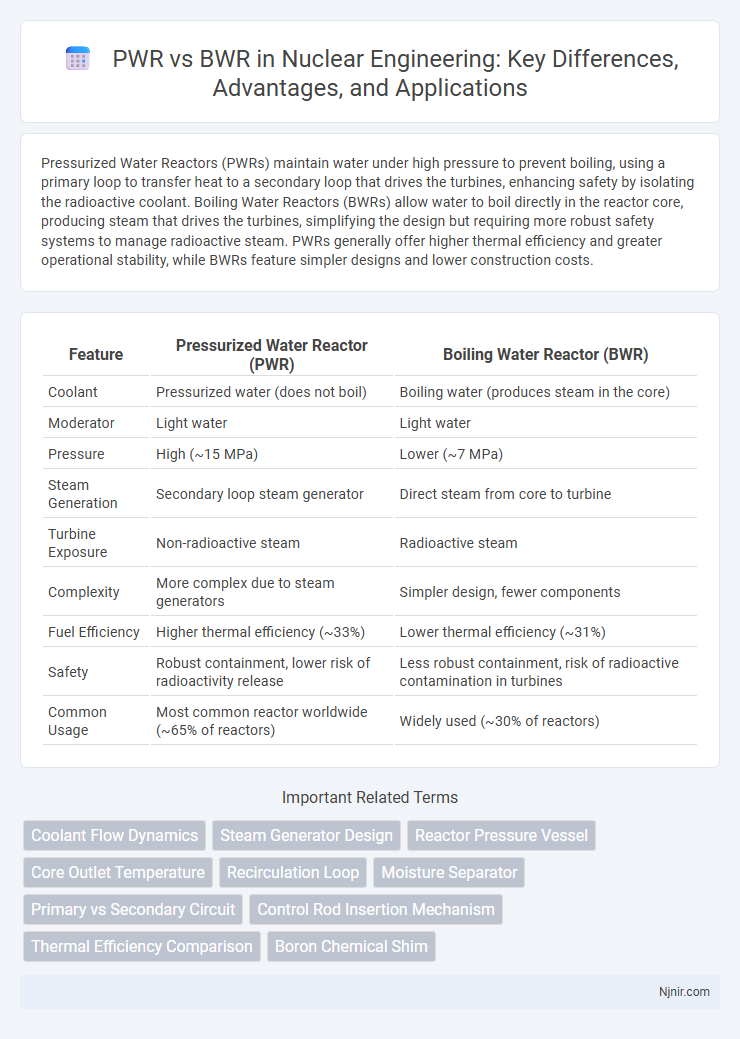

| Feature | Pressurized Water Reactor (PWR) | Boiling Water Reactor (BWR) |

|---|---|---|

| Coolant | Pressurized water (does not boil) | Boiling water (produces steam in the core) |

| Moderator | Light water | Light water |

| Pressure | High (~15 MPa) | Lower (~7 MPa) |

| Steam Generation | Secondary loop steam generator | Direct steam from core to turbine |

| Turbine Exposure | Non-radioactive steam | Radioactive steam |

| Complexity | More complex due to steam generators | Simpler design, fewer components |

| Fuel Efficiency | Higher thermal efficiency (~33%) | Lower thermal efficiency (~31%) |

| Safety | Robust containment, lower risk of radioactivity release | Less robust containment, risk of radioactive contamination in turbines |

| Common Usage | Most common reactor worldwide (~65% of reactors) | Widely used (~30% of reactors) |

Introduction to PWR and BWR Technologies

Pressurized Water Reactors (PWR) use high-pressure water as both coolant and neutron moderator, preventing boiling in the reactor core and transferring heat to a secondary loop for steam generation. Boiling Water Reactors (BWR) allow water to boil directly in the reactor core, producing steam that drives the turbine without a secondary loop. PWR technology typically offers higher operating pressures and enhanced safety features, while BWR designs simplify the steam generation process and reduce the complexity of the coolant system.

Fundamental Design Differences

Pressurized Water Reactors (PWR) maintain coolant under high pressure to prevent boiling, using a primary loop to transfer heat to a secondary loop where steam drives turbines, ensuring separation of radioactive water from turbine components. Boiling Water Reactors (BWR) allow water to boil directly within the reactor core, generating steam that flows directly to the turbine, eliminating the need for a secondary loop and providing simpler design but increased radioactivity in turbine systems. The fundamental design difference lies in PWR's use of pressurized coolant and steam generators versus BWR's direct steam production inside the reactor vessel.

Reactor Core Configuration

Pressurized Water Reactors (PWR) feature a reactor core with fuel assemblies arranged in a compact, square lattice configuration, optimizing neutron flux and heat transfer efficiency. Boiling Water Reactors (BWR) employ a similar fuel assembly design but operate with direct steam generation inside the core, requiring core structures to accommodate two-phase flow and enhance coolant circulation. Core configurations in PWRs typically include control rods inserted from the top, while BWRs use control blades inserted from the bottom, reflecting their distinct operational and safety design requirements.

Coolant and Moderator Systems

Pressurized Water Reactors (PWR) use high-pressure water as both coolant and moderator, preventing boiling in the core and maintaining efficient heat transfer. Boiling Water Reactors (BWR) use water as both coolant and moderator as well, but operate at lower pressure allowing the water to boil directly in the core, generating steam for turbines. The PWR's separate primary and secondary loops improve contamination control, whereas BWR's single loop directly feeds steam to the turbine, impacting complexity and safety management.

Fuel Type and Fuel Cycle

Pressurized Water Reactors (PWR) use low-enriched uranium dioxide fuel with a typical enrichment of 3-5%, and their fuel cycle lasts approximately 18-24 months before refueling. Boiling Water Reactors (BWR) also utilize low-enriched uranium fuel but often operate with slightly lower enrichment levels, typically around 2-4%, and have fuel cycles of about 12-18 months. Both reactor types rely on solid ceramic fuel pellets, yet the refueling frequency and enrichment differences impact overall reactor efficiency and fuel management strategies.

Efficiency and Power Output

Pressurized Water Reactors (PWR) typically achieve higher thermal efficiency, around 33-37%, compared to Boiling Water Reactors (BWR), which generally operate at about 30-34% efficiency. PWRs maintain coolant under high pressure to avoid boiling, enabling higher temperature gradients and improved power output per unit of reactor volume. BWRs generate steam directly in the reactor vessel, which simplifies design but can limit maximum pressure and temperature, thus slightly reducing overall power efficiency.

Safety Features and Risk Management

Pressurized Water Reactors (PWR) utilize a high-pressure primary coolant loop to prevent boiling, enhancing containment of radioactive materials and reducing the risk of coolant loss, whereas Boiling Water Reactors (BWR) allow boiling within the reactor vessel, requiring advanced steam separation and moisture control systems to manage safety risks. PWRs feature multiple redundant safety systems, including pressurizers to maintain coolant pressure and robust emergency core cooling systems (ECCS), while BWRs incorporate diverse ECCS designs and containment spray systems to mitigate pressure buildup and radioactive releases. Risk management in PWRs centers on maintaining reactor pressure boundary integrity and preventing loss-of-coolant accidents (LOCA), whereas BWR safety strategies focus on controlling steam quality and preventing void fraction excursions that could lead to power instabilities or core damage.

Operational Complexity and Maintenance

Pressurized Water Reactors (PWR) exhibit higher operational complexity due to their use of high-pressure primary loops that require robust pressure control and frequent monitoring of steam generators. Boiling Water Reactors (BWR) simplify operations by allowing the reactor core to directly produce steam, reducing the need for separate steam generators but increasing challenges in controlling water chemistry and managing radiological exposure in the turbine system. Maintenance in PWRs demands specialized handling of pressure boundary components and periodic inspection of steam generators, while BWR maintenance focuses more on turbine maintenance and managing stress corrosion in reactor internals due to direct steam production.

Waste Management and Environmental Impact

Pressurized Water Reactors (PWR) produce higher volumes of spent nuclear fuel with longer half-lives, requiring robust long-term storage solutions to manage radioactive waste safely. Boiling Water Reactors (BWR) generate waste with comparatively lower thermal output per unit of fuel, allowing slightly more efficient on-site cooling and reduced heat dissipation challenges. Both reactor types necessitate advanced containment protocols, but PWR's pressurized systems often lead to more complex waste treatment due to higher corrosion potentials in spent fuel assemblies.

Industry Applications and Global Deployment

Pressurized Water Reactors (PWRs) dominate global nuclear power generation, accounting for approximately 65% of operational reactors due to their proven safety and efficiency in large-scale electricity production. Boiling Water Reactors (BWRs) are widely used in countries like the United States and Japan, favored for their simpler design and direct steam generation which reduces plant components. Industry applications for PWRs extend to naval propulsion and large commercial plants, while BWRs are primarily deployed in commercial power generation with over 90 units worldwide, enhancing grid stability and supporting carbon-neutral energy goals.

Coolant Flow Dynamics

Pressurized Water Reactors (PWR) maintain coolant under high pressure to prevent boiling and ensure consistent flow dynamics, while Boiling Water Reactors (BWR) allow coolant to boil and separate steam directly in the core, resulting in distinct two-phase flow characteristics essential for heat transfer efficiency.

Steam Generator Design

Pressurized Water Reactors (PWRs) feature external steam generators with U-tube designs that transfer heat from the primary loop to the secondary loop, while Boiling Water Reactors (BWRs) lack steam generators as boiling occurs directly in the reactor core, producing steam that drives the turbine.

Reactor Pressure Vessel

The Reactor Pressure Vessel (RPV) in a Pressurized Water Reactor (PWR) operates at higher pressures and temperatures with thicker walls compared to the Boiling Water Reactor (BWR) RPV, enhancing structural integrity and safety under pressurized conditions.

Core Outlet Temperature

Pressurized Water Reactors (PWRs) typically have higher core outlet temperatures around 315degC compared to Boiling Water Reactors (BWRs) which operate near 285degC, influencing thermal efficiency and material selection.

Recirculation Loop

The Pressurized Water Reactor (PWR) features a closed-loop primary circuit without a recirculation loop, while the Boiling Water Reactor (BWR) integrates an active recirculation loop to control reactor power and coolant flow.

Moisture Separator

Pressurized Water Reactors (PWR) use steam generators to keep reactor coolant separate from turbine steam, minimizing moisture separator reliance, whereas Boiling Water Reactors (BWR) incorporate moisture separators directly in the steam path to remove water droplets and protect turbines.

Primary vs Secondary Circuit

PWR uses a primary circuit with high-pressure water as both coolant and moderator, transferring heat to a separate secondary circuit to generate steam, while BWR combines primary coolant and steam generation in a single circuit without a separate secondary loop.

Control Rod Insertion Mechanism

Pressurized Water Reactors (PWR) use control rods inserted from the top via a gravity-assisted magnetic latch mechanism, while Boiling Water Reactors (BWR) insert control rods from the bottom using hydraulic-driven control rod drives.

Thermal Efficiency Comparison

Pressurized Water Reactors (PWR) typically achieve thermal efficiencies around 33-35% compared to Boiling Water Reactors (BWR), which have slightly lower thermal efficiencies of approximately 30-33% due to differences in steam generation and operating pressure.

Boron Chemical Shim

PWRs utilize soluble boron chemical shim for reactivity control through boron concentration adjustments in the coolant, whereas BWRs rely primarily on mechanical control rods and jet pumps without soluble boron in the reactor core.

PWR vs BWR Infographic

njnir.com

njnir.com