Pebble bed reactors utilize spherical fuel elements that enhance coolant flow and heat transfer efficiency compared to conventional fuel rods. Their modular design allows for continuous refueling and improved safety through inherent passive cooling mechanisms. This contrasts with traditional rods, which require periodic shutdowns and rely more heavily on active cooling systems.

Table of Comparison

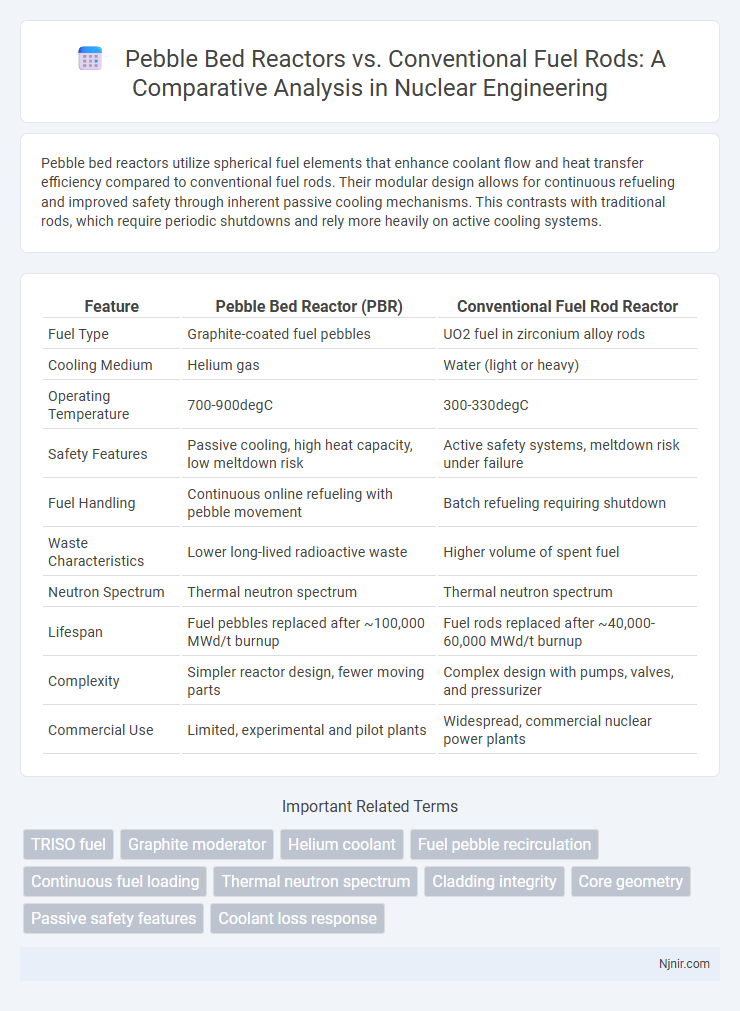

| Feature | Pebble Bed Reactor (PBR) | Conventional Fuel Rod Reactor |

|---|---|---|

| Fuel Type | Graphite-coated fuel pebbles | UO2 fuel in zirconium alloy rods |

| Cooling Medium | Helium gas | Water (light or heavy) |

| Operating Temperature | 700-900degC | 300-330degC |

| Safety Features | Passive cooling, high heat capacity, low meltdown risk | Active safety systems, meltdown risk under failure |

| Fuel Handling | Continuous online refueling with pebble movement | Batch refueling requiring shutdown |

| Waste Characteristics | Lower long-lived radioactive waste | Higher volume of spent fuel |

| Neutron Spectrum | Thermal neutron spectrum | Thermal neutron spectrum |

| Lifespan | Fuel pebbles replaced after ~100,000 MWd/t burnup | Fuel rods replaced after ~40,000-60,000 MWd/t burnup |

| Complexity | Simpler reactor design, fewer moving parts | Complex design with pumps, valves, and pressurizer |

| Commercial Use | Limited, experimental and pilot plants | Widespread, commercial nuclear power plants |

Introduction to Nuclear Reactor Technologies

Pebble bed reactors utilize spherical fuel elements made of uranium fuel encased in graphite, allowing enhanced heat transfer and passive safety features compared to conventional fuel rods composed of cylindrical uranium pellets in metal cladding. The modular design of pebble bed reactors facilitates continuous refueling and higher thermal efficiency due to improved coolant flow dynamics. Conventional reactors rely heavily on solid fuel rods arranged in assemblies, requiring more complex control and cooling systems to manage reactivity and heat removal.

Overview of Pebble Bed Reactor Design

Pebble bed reactors utilize spherical fuel elements called pebbles, each containing thousands of TRISO-coated fuel particles, allowing for inherent safety features through high-temperature tolerance and passive cooling. Conventional fuel rod reactors rely on cylindrical fuel rods arranged in assemblies, which have limited thermal conductivity and require active safety systems to prevent overheating. The pebble bed design enhances neutron moderation and heat transfer efficiency, offering a modular and inherently safer alternative to traditional fuel rod configurations.

Conventional Fuel Rod Reactor Architecture

Conventional fuel rod reactor architecture consists of cylindrical metal tubes filled with uranium oxide pellets arranged in fuel assemblies, which are inserted into the reactor core for fission reactions. This design allows efficient heat transfer through the cladding to the coolant, typically water, enabling effective thermal regulation and steam generation. The structural simplicity and well-established manufacturing processes of fuel rods contribute to their widespread adoption in light water reactors globally.

Fuel Types and Materials Comparison

Pebble bed reactors utilize spherical fuel elements made from uranium dioxide or thorium embedded in graphite, offering enhanced heat resistance and containment compared to conventional cylindrical fuel rods composed of enriched uranium oxide pellets encased in zirconium alloy cladding. The graphite moderator in pebble beds improves neutron economy and thermal conductivity, enabling higher burnup and more efficient fuel utilization than the metal or ceramic cladding in traditional reactors. Differences in fuel geometry and materials influence reactor safety, thermal efficiency, and fuel cycle length, with pebble bed designs emphasizing passive cooling and inherent safety features absent in standard fuel rod assemblies.

Safety Features and Passive Systems

Pebble bed reactors employ spherical fuel elements with high temperature resistance, enhancing safety by preventing meltdown even during loss-of-coolant scenarios, unlike conventional fuel rods prone to overheating and cladding failure. Their design incorporates passive cooling systems relying on natural convection and radiation, eliminating the need for active refrigeration to maintain core temperature. In contrast, conventional reactors depend heavily on active cooling pumps and emergency core cooling systems, increasing vulnerability to mechanical failures during accidents.

Thermal Efficiency and Power Output

Pebble bed reactors achieve higher thermal efficiency due to their superior heat transfer characteristics and continuous fuel circulation, which maintain optimal core temperatures. Their spherical fuel elements allow for better coolant flow and more effective heat removal compared to conventional cylindrical fuel rods, enhancing power output consistency. This design supports higher operating temperatures, resulting in improved thermodynamic efficiency over traditional fuel rod reactors.

Waste Management and Spent Fuel Handling

Pebble bed reactors produce spherical fuel elements that facilitate continuous online refueling and reduce spent fuel volume compared to conventional fuel rods, enabling more efficient waste management. The modular design of pebble beds allows for easier cooling and decay heat removal, minimizing long-term storage challenges associated with spent fuel handling. Conventional fuel rods generate more concentrated, high-activity spent fuel assemblies requiring extensive shielding and pool storage, increasing complexity in waste management and handling processes.

Operational Flexibility and Refueling Methods

Pebble bed reactors offer superior operational flexibility through continuous online refueling, allowing individual fuel pebbles to be added or removed without shutdown, unlike conventional fuel rod reactors that require periodic batch refueling and complete or partial reactor offline status. This continuous refueling process in pebble bed reactors enhances reactor performance and availability by minimizing downtime and enabling flexible power output adjustments. Conventional fuel rods, typically arranged in fixed assemblies, demand complex handling during refueling outages, limiting operational adaptability and resulting in longer maintenance periods.

Economic Considerations and Scalability

Pebble bed reactors offer economic advantages through modular construction, enabling incremental capacity expansion and reduced upfront capital costs compared to conventional fuel rod reactors that require large, capital-intensive facilities. The use of spherical fuel elements in pebble bed reactors allows continuous refueling during operation, enhancing fuel efficiency and lowering operational costs relative to batch-wise refueling in conventional reactors. Scalability is improved in pebble bed designs due to their inherent safety features and passive cooling systems, facilitating smaller, distributed power units ideal for diverse grid demands, unlike conventional reactors which often require large-scale infrastructure and longer construction times.

Future Prospects and Research Directions

Pebble bed reactors offer enhanced safety features through inherent passive cooling and continuous fuel replacement, positioning them as a promising alternative to conventional fuel rod reactors for next-generation nuclear power. Research directions focus on improving fuel pebble resilience, optimizing helium coolant systems, and advancing high-temperature materials to boost thermal efficiency and economic viability. Future prospects emphasize integration with hydrogen production and modular deployment to support flexible, low-carbon energy grids.

TRISO fuel

TRISO fuel in pebble bed reactors offers enhanced safety and higher burnup capacity compared to conventional fuel rods by encapsulating fuel particles within multiple protective layers that withstand extreme temperatures and prevent fission product release.

Graphite moderator

The pebble bed reactor utilizes spherical fuel elements encased in graphite as both fuel and moderator, enhancing neutron moderation and safety compared to conventional fuel rods that separate fuel from graphite moderators.

Helium coolant

Pebble bed reactors use helium coolant for its inert properties and high thermal conductivity, enhancing safety and efficiency compared to conventional fuel rod reactors that typically use water-based coolants.

Fuel pebble recirculation

Fuel pebble recirculation in pebble bed reactors enhances fuel utilization and safety by continuously cycling pebbles through the core, contrasting with the fixed, non-recirculating conventional fuel rods.

Continuous fuel loading

Pebble bed reactors enable continuous fuel loading through spherical fuel elements circulated within the core, enhancing operational efficiency compared to conventional fuel rods that require periodic shutdowns for refueling.

Thermal neutron spectrum

Pebble bed reactors utilize a thermal neutron spectrum moderated by graphite, enabling higher fuel burnup and inherent safety compared to conventional fuel rods moderated by light water producing a different thermal neutron energy distribution.

Cladding integrity

Pebble bed reactors maintain superior cladding integrity compared to conventional fuel rods due to their spherical fuel design, which minimizes thermal stresses and reduces the risk of cladding failure under high-temperature and irradiation conditions.

Core geometry

Pebble bed reactors feature a spherical fuel element core geometry enhancing neutron moderation and heat transfer, unlike the linear arrangement of fuel rods in conventional reactors that limits coolant flow paths.

Passive safety features

Pebble bed reactors enhance passive safety by using spherical fuel elements with low power density and high thermal conductivity, allowing for inherent temperature regulation and resistance to meltdown, unlike conventional fuel rods that rely on active cooling systems.

Coolant loss response

Pebble bed reactors exhibit enhanced coolant loss response by utilizing a modular design with spherical fuel elements and helium coolant, enabling passive heat removal and reducing the risk of meltdown compared to conventional fuel rod reactors reliant on active water coolant systems.

pebble bed reactor vs conventional fuel rod Infographic

njnir.com

njnir.com