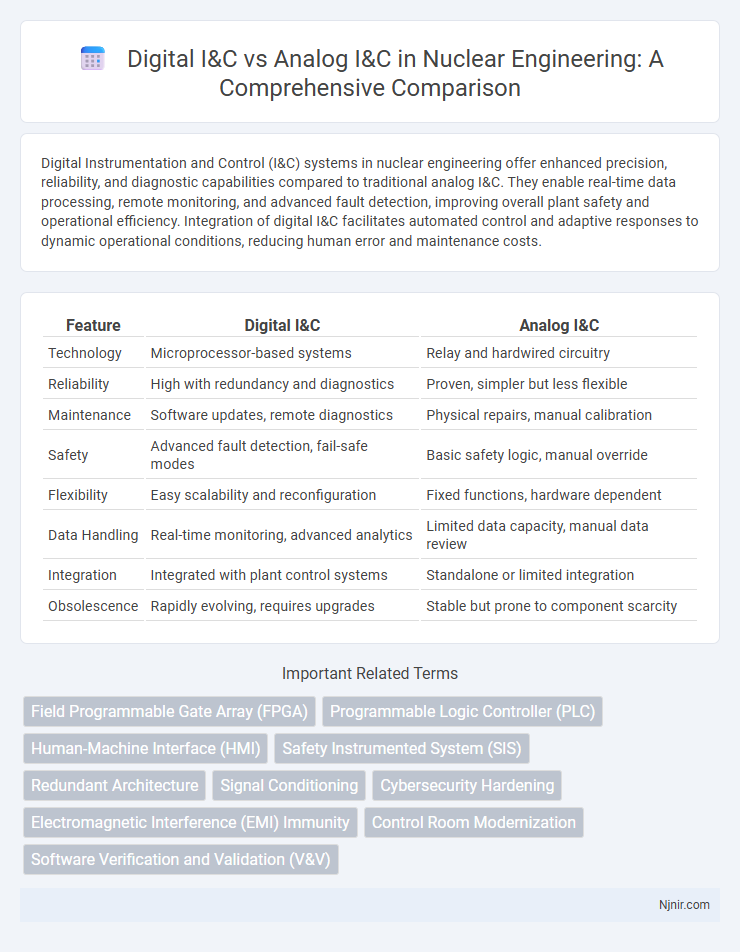

Digital Instrumentation and Control (I&C) systems in nuclear engineering offer enhanced precision, reliability, and diagnostic capabilities compared to traditional analog I&C. They enable real-time data processing, remote monitoring, and advanced fault detection, improving overall plant safety and operational efficiency. Integration of digital I&C facilitates automated control and adaptive responses to dynamic operational conditions, reducing human error and maintenance costs.

Table of Comparison

| Feature | Digital I&C | Analog I&C |

|---|---|---|

| Technology | Microprocessor-based systems | Relay and hardwired circuitry |

| Reliability | High with redundancy and diagnostics | Proven, simpler but less flexible |

| Maintenance | Software updates, remote diagnostics | Physical repairs, manual calibration |

| Safety | Advanced fault detection, fail-safe modes | Basic safety logic, manual override |

| Flexibility | Easy scalability and reconfiguration | Fixed functions, hardware dependent |

| Data Handling | Real-time monitoring, advanced analytics | Limited data capacity, manual data review |

| Integration | Integrated with plant control systems | Standalone or limited integration |

| Obsolescence | Rapidly evolving, requires upgrades | Stable but prone to component scarcity |

Introduction to Nuclear Instrumentation and Control (I&C)

Digital Instrumentation and Control (I&C) in nuclear systems offers enhanced precision, real-time data processing, and improved fault diagnostics compared to traditional analog I&C, which relies on continuous signals and simpler feedback mechanisms. Digital I&C systems integrate advanced microprocessors and software algorithms, enabling more reliable monitoring and control of reactor operations, safety systems, and process parameters. The transition from analog to digital technology in nuclear I&C enhances system flexibility, facilitates scalability, and supports automated safety functions critical to nuclear reactor performance and regulatory compliance.

Evolution from Analog to Digital I&C Systems

The evolution from analog to digital instrumentation and control (I&C) systems reflects significant advancements in precision, reliability, and functionality within industrial automation and process control. Digital I&C systems offer enhanced data processing capabilities, improved diagnostics, and easier integration with modern communication networks compared to traditional analog counterparts. This transition supports higher operational efficiency, better fault detection, and scalability in complex industrial environments such as nuclear power plants and manufacturing facilities.

Key Components of Analog I&C in Nuclear Facilities

Key components of analog Instrumentation and Control (I&C) systems in nuclear facilities include sensors, transmitters, controllers, and actuators that operate through continuous signal modulation. These components rely on physical electrical signals, such as voltage or current, to measure parameters like temperature, pressure, and flow within the reactor environment. Analog I&C systems prioritize reliability and simplicity with hardwired connections, making them resilient to electromagnetic interference compared to digital counterparts.

Core Features of Digital I&C Architecture

Digital Instrumentation and Control (I&C) architecture offers enhanced precision, real-time data processing, and integration capabilities compared to analog systems. Key features include modular design for scalability, fault-tolerant mechanisms ensuring system reliability, and advanced diagnostics enabled by software-based monitoring. This architecture supports seamless communication between components through networked protocols, facilitating improved control accuracy and maintenance efficiency.

Reliability and Safety Considerations

Digital instrumentation and control (I&C) systems offer enhanced reliability through advanced diagnostic capabilities and fault tolerance compared to analog I&C systems, which rely on continuous signal processing with limited self-monitoring features. Safety considerations favor digital I&C due to improved redundancy, error detection, and software-based protection mechanisms that reduce the likelihood of undetected failures. However, digital systems require rigorous cybersecurity measures and validation of complex software algorithms to maintain safe operation, whereas analog systems, despite their simplicity, are less vulnerable to cyber threats but may suffer from signal degradation and aging components.

Cybersecurity Challenges and Mitigation

Digital Instrumentation and Control (I&C) systems introduce increased cybersecurity risks compared to analog I&C due to their reliance on network connectivity and software-based components, which are vulnerable to cyberattacks such as malware, unauthorized access, and data breaches. Mitigation strategies include implementing robust firewalls, intrusion detection systems, regular software updates, and strict access controls to protect digital I&C environments from cyber threats. Cybersecurity frameworks like IEC 62443 and rigorous risk assessments enhance resilience by addressing specific vulnerabilities inherent to digital I&C architectures.

Human-Machine Interface: Analog vs Digital

Digital Human-Machine Interfaces (HMIs) offer enhanced data visualization, intuitive touchscreens, and real-time feedback compared to analog HMIs, which rely on physical gauges and manual controls. Digital HMIs enable seamless integration with control systems and remote monitoring, improving operational efficiency and accuracy. Analog HMIs provide simplicity and reliability in harsh environments but lack the advanced diagnostic and customization features inherent in digital systems.

Regulatory Perspectives and Licensing Issues

Digital Instrumentation and Control (I&C) systems offer enhanced diagnostic capabilities and improved accuracy compared to analog I&C, but regulatory bodies emphasize the need for rigorous software verification, validation, and cybersecurity measures. Licensing processes for digital I&C require comprehensive safety analysis and demonstration of compliance with standards such as IEC 61513 and NRC Regulatory Guide 1.152, addressing software common-cause failures and hardware reliability. Analog I&C systems benefit from well-established regulatory precedents, but face challenges in meeting evolving safety and security requirements in modern nuclear facility licensing.

Lifecycle Costs and Maintenance Needs

Digital Instrumentation and Control (I&C) systems offer lower lifecycle costs compared to analog I&C due to reduced wiring complexity, enhanced diagnostics, and ease of software updates. Maintenance needs for digital I&C are minimized with automated fault detection and remote troubleshooting capabilities, contrasting with the frequent manual calibrations and adjustments required by analog systems. Over time, digital I&C decreases downtime and labor costs, making it a cost-effective solution for industrial process control.

Future Trends in Nuclear I&C Technologies

Future trends in nuclear Instrumentation and Control (I&C) technologies emphasize the shift from analog to digital systems due to enhanced precision, reliability, and data integration capabilities. Digital I&C enables real-time monitoring, advanced diagnostics, and predictive maintenance through sophisticated software algorithms and sensor networks, improving overall safety and efficiency in nuclear reactors. Integration of artificial intelligence and cybersecurity measures is becoming critical to address vulnerabilities and optimize automated control processes in next-generation nuclear power plants.

Field Programmable Gate Array (FPGA)

Field Programmable Gate Arrays (FPGAs) in digital Instrumentation and Control (I&C) systems offer enhanced flexibility, faster processing speeds, and improved reliability compared to traditional analog I&C by enabling customizable hardware configurations and real-time data handling.

Programmable Logic Controller (PLC)

Programmable Logic Controllers (PLCs) in digital Instrumentation and Control (I&C) systems offer enhanced reliability, flexibility, and real-time data processing compared to traditional analog I&C, enabling precise automation and improved system diagnostics.

Human-Machine Interface (HMI)

Digital I&C systems enhance Human-Machine Interface (HMI) efficiency by providing real-time data visualization, customizable displays, and advanced diagnostic capabilities compared to traditional analog I&C.

Safety Instrumented System (SIS)

Digital I&C enhances Safety Instrumented System (SIS) reliability and diagnostics by enabling advanced fault detection and real-time monitoring compared to traditional analog I&C.

Redundant Architecture

Digital I&C systems offer enhanced redundant architecture capabilities compared to analog I&C by enabling real-time fault detection, automatic failover, and diverse software-based backup pathways that significantly improve system reliability and safety in critical industrial applications.

Signal Conditioning

Digital I&C offers precise signal conditioning with enhanced noise reduction and easier calibration compared to analog I&C, which relies on continuous signals but may suffer from signal degradation and limited filtering capabilities.

Cybersecurity Hardening

Digital I&C systems enhance cybersecurity hardening by enabling advanced encryption, real-time threat detection, and automated response protocols compared to analog I&C's limited protection mechanisms.

Electromagnetic Interference (EMI) Immunity

Digital I&C systems exhibit higher Electromagnetic Interference (EMI) immunity compared to analog I&C, enabling more reliable performance in industrial and nuclear control environments.

Control Room Modernization

Digital I&C systems enable advanced Control Room Modernization by providing enhanced real-time data integration, improved diagnostics, and streamlined operator interfaces compared to traditional analog I&C systems.

Software Verification and Validation (V&V)

Digital I&C systems require more rigorous and comprehensive software Verification and Validation (V&V) processes compared to analog I&C due to their complexity, programmability, and susceptibility to software-related failures.

digital I&C vs analog I&C Infographic

njnir.com

njnir.com