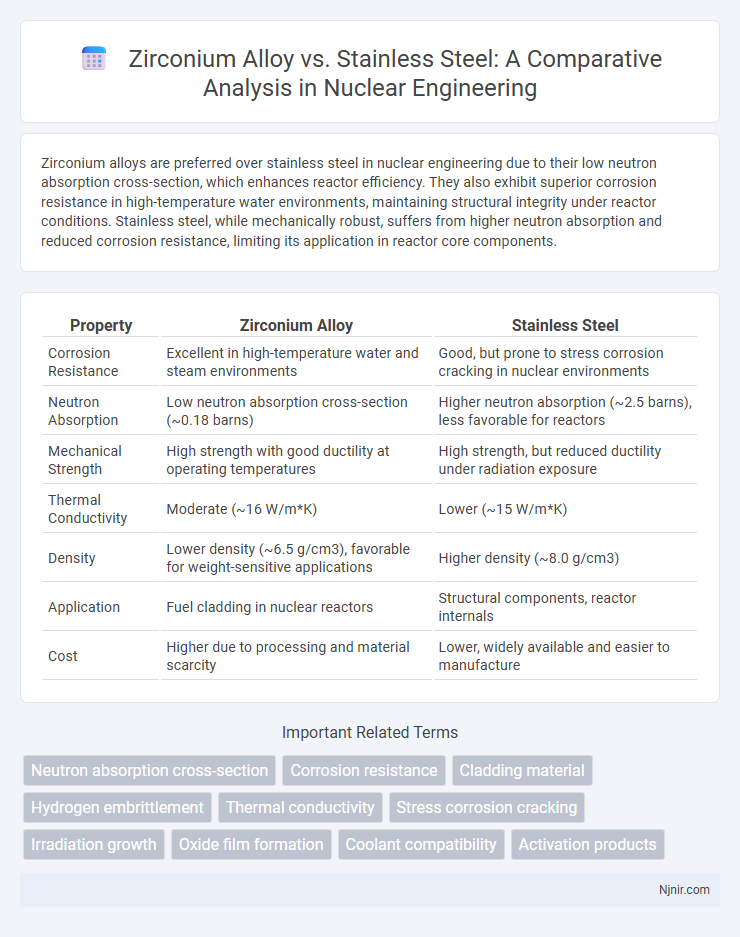

Zirconium alloys are preferred over stainless steel in nuclear engineering due to their low neutron absorption cross-section, which enhances reactor efficiency. They also exhibit superior corrosion resistance in high-temperature water environments, maintaining structural integrity under reactor conditions. Stainless steel, while mechanically robust, suffers from higher neutron absorption and reduced corrosion resistance, limiting its application in reactor core components.

Table of Comparison

| Property | Zirconium Alloy | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent in high-temperature water and steam environments | Good, but prone to stress corrosion cracking in nuclear environments |

| Neutron Absorption | Low neutron absorption cross-section (~0.18 barns) | Higher neutron absorption (~2.5 barns), less favorable for reactors |

| Mechanical Strength | High strength with good ductility at operating temperatures | High strength, but reduced ductility under radiation exposure |

| Thermal Conductivity | Moderate (~16 W/m*K) | Lower (~15 W/m*K) |

| Density | Lower density (~6.5 g/cm3), favorable for weight-sensitive applications | Higher density (~8.0 g/cm3) |

| Application | Fuel cladding in nuclear reactors | Structural components, reactor internals |

| Cost | Higher due to processing and material scarcity | Lower, widely available and easier to manufacture |

Introduction to Materials in Nuclear Engineering

Zirconium alloys exhibit exceptional corrosion resistance and low neutron absorption cross-section, making them ideal cladding materials for fuel rods in nuclear reactors. Stainless steel, while mechanically robust and resistant to oxidation, has a higher neutron absorption rate, which can negatively impact reactor efficiency. The choice between zirconium alloys and stainless steel directly influences reactor performance, safety, and fuel economy in nuclear engineering applications.

Overview of Zirconium Alloys

Zirconium alloys exhibit exceptional corrosion resistance, particularly in aggressive environments such as nuclear reactors, making them ideal for cladding fuel rods. These alloys feature low neutron absorption cross-sections, enhancing their suitability in nuclear applications compared to stainless steel, which has higher magnetic permeability and lower resistance to certain corrosive agents. Their mechanical strength and thermal stability at elevated temperatures surpass that of common stainless steel grades, contributing to superior performance in demanding industrial processes.

Overview of Stainless Steel

Stainless steel is an iron-based alloy known for its high corrosion resistance, durability, and strength due to the presence of chromium and nickel. Commonly used in construction, medical instruments, and kitchenware, stainless steel offers excellent resistance to oxidation and staining in various environments. Its versatility and cost-effectiveness make it a popular choice compared to specialized metals like zirconium alloys.

Mechanical Properties Comparison

Zirconium alloys exhibit superior corrosion resistance and lower density compared to stainless steel, making them ideal for high-performance applications where weight and chemical stability are critical. While stainless steel offers higher tensile strength and better wear resistance, zirconium alloys deliver enhanced ductility and fracture toughness, especially under high-temperature and radiation-exposed environments. The mechanical properties of zirconium alloys, such as yield strength (up to 550 MPa) and Young's modulus (around 100 GPa), combined with exceptional resistance to stress corrosion cracking, often outperform stainless steel variants in nuclear and aerospace industries.

Corrosion Resistance in Reactor Environments

Zirconium alloys exhibit superior corrosion resistance in reactor environments compared to stainless steel, primarily due to their stable oxide layer that effectively resists oxidation and hydrogen uptake under high-temperature water and steam conditions. Stainless steel tends to suffer from stress corrosion cracking and pitting corrosion in aggressive reactor coolant environments, especially under prolonged exposure to neutron radiation. The corrosion resistance of zirconium alloys makes them the preferred material for fuel cladding and structural components in nuclear reactors, enhancing operational safety and longevity.

Neutron Absorption Characteristics

Zirconium alloys exhibit significantly lower neutron absorption cross-sections compared to stainless steel, making them highly suitable for nuclear reactor applications where neutron economy is critical. Stainless steel contains iron, chromium, and nickel, elements with higher neutron absorption rates that can reduce reactor efficiency and fuel utilization. The superior neutron transparency of zirconium alloys enhances neutron flux and supports sustained chain reactions in light water reactors.

Fabrication and Manufacturability

Zirconium alloy exhibits superior corrosion resistance and biocompatibility compared to stainless steel, making it ideal for chemical processing and medical applications where fabrication demands precise welding and high-temperature forming. Stainless steel offers greater machinability and cost-effectiveness, with well-established fabrication techniques including stamping, bending, and welding suitable for a broad range of industrial uses. The manufacturability of zirconium alloys is generally more complex due to their reactive nature at elevated temperatures, requiring controlled environments and specialized equipment to maintain material integrity during forming and joining processes.

Performance in High-Temperature Conditions

Zirconium alloy exhibits superior corrosion resistance and strength retention at high temperatures compared to stainless steel, making it ideal for nuclear reactors and chemical processing environments. Stainless steel, while offering good thermal stability and mechanical properties, tends to oxidize and weaken more rapidly under prolonged exposure to extreme heat. The low neutron absorption cross-section of zirconium alloy further enhances its performance in high-temperature nuclear applications where material integrity and durability are critical.

Cost and Availability Analysis

Zirconium alloys exhibit higher material costs compared to stainless steel due to the complex extraction and refining process involved in zirconium production. Stainless steel benefits from widespread availability and a well-established supply chain, resulting in significantly lower prices and quicker procurement times. Cost-effectiveness of stainless steel makes it the preferred choice for large-scale industrial applications, whereas zirconium alloys are reserved for specialized uses requiring superior corrosion resistance despite higher expenditures.

Applications in Nuclear Reactor Components

Zirconium alloys are preferred in nuclear reactor components due to their low neutron absorption cross-section and excellent corrosion resistance in high-temperature water environments, essential for fuel cladding and core structural materials. Stainless steel, while offering superior mechanical strength and corrosion resistance, exhibits higher neutron absorption, limiting its use mainly to non-fuel structural components and reactor internals. The choice between zirconium alloy and stainless steel impacts reactor efficiency, safety, and fuel cycle performance in pressurized water reactors (PWR) and boiling water reactors (BWR).

Neutron absorption cross-section

Zirconium alloy exhibits a significantly lower neutron absorption cross-section compared to stainless steel, making it the preferred material for nuclear reactor cladding to enhance neutron economy.

Corrosion resistance

Zirconium alloy exhibits superior corrosion resistance compared to stainless steel, especially in aggressive environments such as acidic and high-temperature conditions.

Cladding material

Zirconium alloy cladding offers superior corrosion resistance and neutron absorption properties compared to stainless steel, making it the preferred material for nuclear fuel rod cladding.

Hydrogen embrittlement

Zirconium alloys exhibit significantly greater resistance to hydrogen embrittlement compared to stainless steel due to their superior hydrogen diffusivity and stable oxide layer formation.

Thermal conductivity

Zirconium alloy exhibits significantly lower thermal conductivity than stainless steel, making it more effective for applications requiring thermal insulation under high-temperature conditions.

Stress corrosion cracking

Zirconium alloy exhibits superior resistance to stress corrosion cracking compared to stainless steel, making it ideal for high-stress, corrosive environments such as nuclear reactors.

Irradiation growth

Zirconium alloy exhibits significantly lower irradiation growth compared to stainless steel, making it more suitable for nuclear reactor applications requiring dimensional stability under neutron radiation.

Oxide film formation

Zirconium alloy forms a highly stable and protective zirconium oxide film that enhances corrosion resistance in aggressive environments compared to the less effective chromium oxide film on stainless steel.

Coolant compatibility

Zirconium alloy exhibits superior coolant compatibility compared to stainless steel due to its low neutron absorption and corrosion resistance in high-temperature water environments.

Activation products

Zirconium alloys produce significantly lower activation products compared to stainless steel, making them more suitable for nuclear reactor applications due to reduced long-term radioactivity.

zirconium alloy vs stainless steel Infographic

njnir.com

njnir.com