Small Modular Reactors (SMRs) offer flexible and cost-effective deployment advantages compared to large-scale plant refurbishments, enabling faster construction times and reduced financial risk. SMRs facilitate incremental capacity additions and improved grid integration, addressing energy demand fluctuations more efficiently than traditional nuclear plants. The modular design of SMRs also enhances safety features and scalability, positioning them as a strategic complement or alternative to lengthy and expensive refurbishment projects of existing large reactors.

Table of Comparison

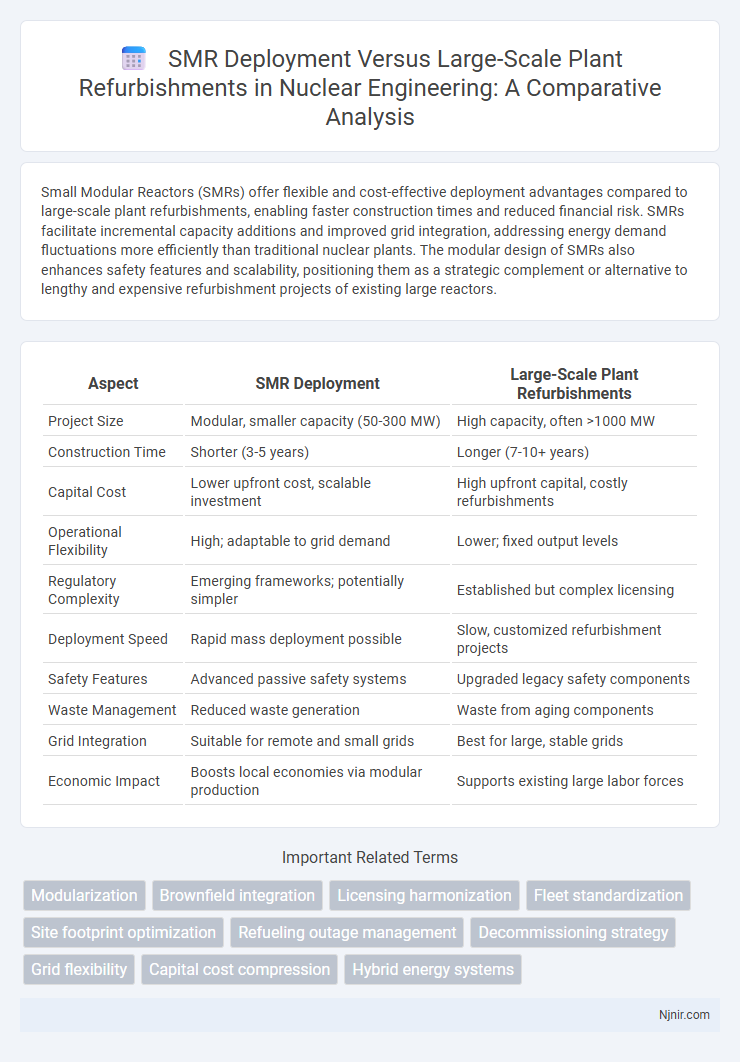

| Aspect | SMR Deployment | Large-Scale Plant Refurbishments |

|---|---|---|

| Project Size | Modular, smaller capacity (50-300 MW) | High capacity, often >1000 MW |

| Construction Time | Shorter (3-5 years) | Longer (7-10+ years) |

| Capital Cost | Lower upfront cost, scalable investment | High upfront capital, costly refurbishments |

| Operational Flexibility | High; adaptable to grid demand | Lower; fixed output levels |

| Regulatory Complexity | Emerging frameworks; potentially simpler | Established but complex licensing |

| Deployment Speed | Rapid mass deployment possible | Slow, customized refurbishment projects |

| Safety Features | Advanced passive safety systems | Upgraded legacy safety components |

| Waste Management | Reduced waste generation | Waste from aging components |

| Grid Integration | Suitable for remote and small grids | Best for large, stable grids |

| Economic Impact | Boosts local economies via modular production | Supports existing large labor forces |

Overview of SMR Deployment and Large-Scale Plant Refurbishments

SMR deployment offers modular, scalable nuclear power solutions with reduced construction times and lower upfront capital compared to traditional large-scale plant refurbishments, which involve extensive overhauls to extend the operational life of existing reactors. Small Modular Reactors provide enhanced flexibility for grid integration and incremental capacity additions, whereas large-scale refurbishments require significant downtime and investment to upgrade aging infrastructure while maintaining regulatory compliance. The strategic choice between SMRs and large-scale refurbishments depends on regional energy demands, legacy fleet conditions, and long-term decarbonization goals.

Comparative Cost Analysis: SMRs vs. Plant Refurbishments

Small Modular Reactors (SMRs) offer lower upfront capital costs and shorter construction timelines compared to large-scale plant refurbishments, which often involve extensive downtime and higher labor expenses. Levelized cost of electricity (LCOE) for SMRs can be more competitive due to modular factory production and scalability, whereas refurbishments typically face increasing costs with aging infrastructure and regulatory compliance. Economic assessments indicate SMRs provide financial flexibility and reduced risk, while refurbishments may incur unpredictable maintenance expenditures and extended project durations.

Deployment Timelines and Flexibility

Small Modular Reactors (SMRs) offer significantly shorter deployment timelines compared to large-scale plant refurbishments, often taking 3 to 5 years versus 10 to 20 years for refurbishment projects. SMRs provide enhanced flexibility through modular construction and scalable capacity, enabling incremental additions to energy infrastructure tailored to demand. Large-scale refurbishments require extensive outages and complex logistical coordination, whereas SMRs allow for off-site fabrication and rapid on-site assembly, minimizing operational disruptions.

Safety and Regulatory Considerations

SMR deployment emphasizes enhanced safety features including passive cooling systems and modular designs that simplify regulatory approvals compared to complex large-scale plant refurbishments, which often face prolonged and costly licensing due to aging infrastructure and extensive safety retrofits. Regulatory frameworks for SMRs are evolving to accommodate their standardized, factory-built modules, enabling streamlined inspections and risk assessments, whereas large-scale refurbishments require comprehensive reviews to address legacy design compliance and updated safety standards. Safety considerations for SMRs focus on inherent risk reduction and emergency response improvements, contrasting with large plants that must integrate advanced safety systems into older configurations, demanding rigorous regulatory scrutiny.

Grid Integration and Scalability

SMR deployment offers enhanced grid integration through modular and flexible power output, enabling smoother adaptation to variable demand and renewable energy sources. Unlike large-scale plant refurbishments with fixed capacity and longer downtime, SMRs can be incrementally deployed to scale capacity efficiently and minimize grid disruption. This modular scalability supports gradual expansion, improving overall grid stability and facilitating the transition to low-carbon energy systems.

Environmental Impact and Sustainability

Small Modular Reactors (SMRs) offer significant environmental advantages over large-scale plant refurbishments by producing lower greenhouse gas emissions during construction and operation due to their smaller size and modular nature. Their reduced land footprint and potential for factory fabrication minimize habitat disruption and resource consumption, enhancing overall sustainability. SMRs enable quicker deployment and can integrate advanced safety and waste reduction technologies, further supporting environmental protection and long-term sustainable energy goals.

Financing and Investment Models

SMR deployment leverages modular construction and standardized designs, enabling phased investment and reduced capital risk compared to large-scale plant refurbishments that demand significant upfront capital and extensive financing arrangements. Financing models for SMRs often incorporate public-private partnerships, green bonds, and innovative lease structures to attract diverse investors, while large-scale refurbishment projects typically rely on traditional long-term debt financing and government subsidies due to their high capital intensity. Investment strategies for SMRs emphasize scalability and cost predictability, making them more attractive for incremental deployment and risk mitigation than the complex, capital-heavy funding approaches required for refurbishing existing nuclear facilities.

Workforce and Skill Requirements

SMR deployment demands a highly specialized workforce with expertise in modular construction, digital technologies, and advanced reactor designs, contrasting with the traditional large-scale plant refurbishments that require extensive experience in legacy systems and heavy civil engineering. The smaller, factory-fabricated nature of SMRs facilitates rapid on-site assembly, reducing the need for large-scale labor but increasing reliance on skilled technicians and automated processes. Workforce training programs must evolve to emphasize cross-disciplinary skills in nuclear engineering, robotics, and software, addressing the dynamic operational requirements unique to SMR technology.

Public Perception and Community Acceptance

SMR deployment often benefits from higher public perception and community acceptance due to its smaller footprint, reduced construction time, and perceived enhanced safety compared to large-scale plant refurbishments. Communities tend to view SMRs as less disruptive and more adaptable to local energy needs, which can lead to faster regulatory approvals and smoother project implementation. Conversely, large-scale plant refurbishments may face skepticism because of their extensive scale, longer timelines, and historical safety concerns linked to aging infrastructure.

Future Prospects in Nuclear Energy Infrastructure

Small Modular Reactors (SMRs) offer flexible and scalable deployment options compared to large-scale plant refurbishments, reducing upfront capital costs and construction timelines in nuclear energy infrastructure. Advances in SMR technology enable integration with renewable grids and remote site applications, supporting decarbonization targets while enhancing grid resilience. Future prospects highlight regulatory streamlining and modular fabrication as key drivers for accelerating nuclear energy capacity growth worldwide.

Modularization

Modularization in SMR deployment significantly reduces construction time and costs compared to large-scale plant refurbishments by enabling factory-built, scalable components that simplify on-site assembly.

Brownfield integration

SMR deployment enables efficient brownfield integration by minimizing site disruption and reducing capital costs compared to large-scale plant refurbishments.

Licensing harmonization

Harmonizing licensing processes for SMR deployment accelerates regulatory approval compared to complex, time-consuming large-scale plant refurbishments.

Fleet standardization

SMR deployment enhances fleet standardization by enabling modular, uniform reactor units that reduce complexity and costs compared to diverse, large-scale plant refurbishments.

Site footprint optimization

SMR deployment significantly reduces site footprint compared to large-scale plant refurbishments by enabling modular, compact installations that optimize land use and minimize environmental impact.

Refueling outage management

SMR deployment offers significantly reduced refueling outage durations compared to large-scale plant refurbishments, enhancing operational efficiency and minimizing downtime.

Decommissioning strategy

SMR deployment streamlines decommissioning strategy by enabling modular, phased dismantling that reduces downtime and waste compared to the complex, large-scale plant refurbishments requiring extensive, centralized dismantling and prolonged site restoration.

Grid flexibility

SMR deployment enhances grid flexibility by enabling modular, scalable power generation that can quickly respond to demand fluctuations, unlike large-scale plant refurbishments which often involve lengthy downtime and less adaptive output adjustments.

Capital cost compression

Small modular reactors (SMRs) offer significant capital cost compression compared to large-scale plant refurbishments by enabling modular construction, reducing on-site labor, and lowering upfront investment risks.

Hybrid energy systems

Hybrid energy systems integrating Small Modular Reactors (SMRs) enable faster deployment and flexible scalability compared to large-scale plant refurbishments, enhancing grid resilience and reducing downtime during energy transitions.

SMR deployment vs large-scale plant refurbishments Infographic

njnir.com

njnir.com