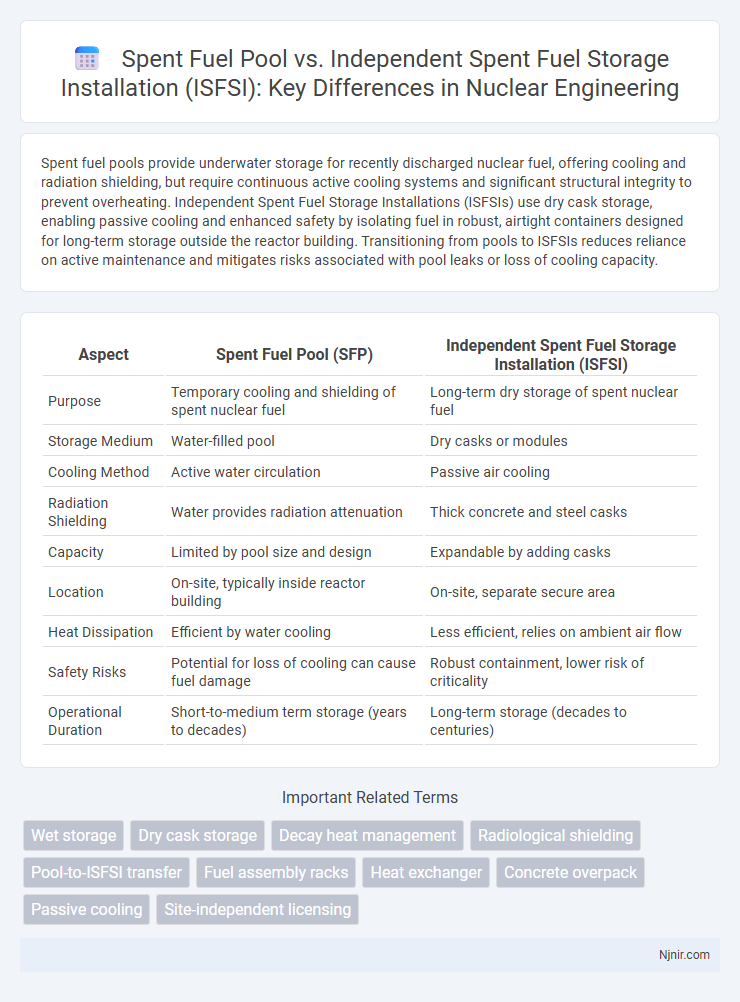

Spent fuel pools provide underwater storage for recently discharged nuclear fuel, offering cooling and radiation shielding, but require continuous active cooling systems and significant structural integrity to prevent overheating. Independent Spent Fuel Storage Installations (ISFSIs) use dry cask storage, enabling passive cooling and enhanced safety by isolating fuel in robust, airtight containers designed for long-term storage outside the reactor building. Transitioning from pools to ISFSIs reduces reliance on active maintenance and mitigates risks associated with pool leaks or loss of cooling capacity.

Table of Comparison

| Aspect | Spent Fuel Pool (SFP) | Independent Spent Fuel Storage Installation (ISFSI) |

|---|---|---|

| Purpose | Temporary cooling and shielding of spent nuclear fuel | Long-term dry storage of spent nuclear fuel |

| Storage Medium | Water-filled pool | Dry casks or modules |

| Cooling Method | Active water circulation | Passive air cooling |

| Radiation Shielding | Water provides radiation attenuation | Thick concrete and steel casks |

| Capacity | Limited by pool size and design | Expandable by adding casks |

| Location | On-site, typically inside reactor building | On-site, separate secure area |

| Heat Dissipation | Efficient by water cooling | Less efficient, relies on ambient air flow |

| Safety Risks | Potential for loss of cooling can cause fuel damage | Robust containment, lower risk of criticality |

| Operational Duration | Short-to-medium term storage (years to decades) | Long-term storage (decades to centuries) |

Introduction to Spent Fuel Management

Spent fuel pools provide underwater storage for cooling and shielding of irradiated nuclear fuel assemblies immediately after reactor discharge, ensuring heat removal and radiation protection. Independent Spent Fuel Storage Installations (ISFSIs) are dry cask storage systems designed for long-term onsite containment of spent fuel after it has sufficiently cooled in pools, offering enhanced safety and easier monitoring. Both methods are integral to spent fuel management strategies, balancing interim storage needs with regulatory compliance and environmental protection.

Overview of Spent Fuel Pools

Spent fuel pools are large, deep basins filled with water designed to cool and shield spent nuclear fuel assemblies immediately after removal from the reactor core, preventing radiation exposure and overheating. These pools provide safe, temporary storage for spent fuel, typically for several years, allowing radioactivity and heat to diminish before transfer to dry cask storage at an Independent Spent Fuel Storage Installation (ISFSI). The high-density water in spent fuel pools serves both as a radiation barrier and a heat sink, ensuring secure management of radioactive materials during the initial cooling period.

Overview of Independent Spent Fuel Storage Installations (ISFSI)

Independent Spent Fuel Storage Installations (ISFSIs) are specialized facilities designed for the dry storage of spent nuclear fuel after it has been cooled in spent fuel pools. These installations use robust, sealed casks made of steel and concrete to safely contain radioactive material, providing enhanced protection against environmental and security risks. ISFSIs offer long-term, on-site storage solutions that reduce reliance on wet storage pools, improve safety margins, and facilitate the management of spent fuel until final disposal or reprocessing options become available.

Safety Considerations: Pool vs. ISFSI

Spent fuel pools provide water shielding that effectively cools and contains radiation from spent nuclear fuel, offering proven protection against radiation exposure and criticality accidents. Independent Spent Fuel Storage Installations (ISFSIs) utilize dry cask storage with robust, passive cooling systems and thick concrete barriers, minimizing risks associated with water loss or leaks. ISFSIs enhance safety by reducing dependencies on active cooling systems, lowering the probability of fuel degradation and radiological release compared to spent fuel pools.

Storage Capacity and Scalability

Spent fuel pools typically offer high-density wet storage for hundreds to thousands of spent nuclear fuel assemblies with limited immediate expansion due to physical space and structural constraints. Independent Spent Fuel Storage Installations (ISFSIs) provide dry cask storage with modular scalability, allowing incremental capacity increases by adding additional casks or storage pads on-site. ISFSIs are preferred for long-term storage scalability since they can be expanded without the extensive infrastructure modification required by spent fuel pools.

Regulatory and Licensing Differences

Spent fuel pools are regulated under reactor operating licenses with continuous oversight by the Nuclear Regulatory Commission (NRC) involving stringent safety, security, and environmental requirements. Independent Spent Fuel Storage Installations (ISFSIs) require specific NRC licenses distinct from reactor licenses, emphasizing dry cask storage safety, long-term containment, and site-specific environmental impact evaluations. Licensing for ISFSIs involves detailed safety analysis reports and periodic inspections focusing on structural integrity and radiological protection separate from reactor operational protocols.

Security Measures and Threat Assessments

Spent fuel pools rely on robust underwater shielding and continuous monitoring systems to prevent radiological release and unauthorized access, with security measures including physical barriers, surveillance cameras, and armed guards to counteract sabotage or theft. Independent Spent Fuel Storage Installations (ISFSIs) enhance security by utilizing dry cask storage with reinforced concrete and steel containment, designed to withstand natural disasters and terrorist attacks according to Nuclear Regulatory Commission (NRC) threat assessment protocols. Both systems undergo rigorous threat evaluations encompassing insider and outsider scenarios, with ISFSIs generally favoring hardened defense-in-depth strategies tailored to long-term storage risks.

Cost Analysis: Construction, Maintenance, and Decommissioning

Spent fuel pools require significant upfront construction costs due to extensive underwater infrastructure and robust safety systems, while ISFSIs involve modular dry cask storage units with relatively lower initial capital investment. Maintenance expenses for spent fuel pools are higher because of continuous water quality monitoring, filtration, and potential corrosion control, whereas ISFSIs demand less frequent inspections and simpler upkeep. Decommissioning spent fuel pools is complex and costly due to hazardous water removal and structural dismantling, contrasting with ISFSIs that offer simpler, more cost-effective decommissioning by removing dry casks and minimal site remediation.

Environmental Impact and Long-Term Sustainability

Spent fuel pools use large volumes of water to cool and shield radioactivity, posing risks of water contamination and thermal pollution in case of leaks, whereas Independent Spent Fuel Storage Installations (ISFSIs) rely on dry cask storage, minimizing water usage and reducing contamination hazards. ISFSIs provide enhanced long-term sustainability by offering passive cooling and robust containment, making them less vulnerable to external environmental factors and natural disasters compared to spent fuel pools. The dry storage approach of ISFSIs also lowers long-term environmental impact through reduced resource consumption and simplified maintenance requirements.

Future Trends in Spent Fuel Storage Technologies

Spent fuel pool storage is gradually being supplemented by Independent Spent Fuel Storage Installations (ISFSIs) that utilize advanced dry cask storage systems designed for longer-term safety and enhanced radiation shielding. Future trends emphasize modular, scalable ISFSI designs incorporating inert gas atmospheres and state-of-the-art monitoring technologies to improve thermal management and structural integrity. Innovations in materials science are driving corrosion-resistant cask components and improved sealing mechanisms, enabling more secure, cost-effective management of spent nuclear fuel over extended timescales.

Wet storage

Spent fuel pools provide wet storage by submerging used nuclear fuel rods in water to cool and shield radiation, whereas Independent Spent Fuel Storage Installations (ISFSIs) primarily utilize dry storage methods instead of wet storage.

Dry cask storage

Dry cask storage in Independent Spent Fuel Storage Installations (ISFSIs) offers enhanced safety and long-term containment for spent nuclear fuel compared to underwater storage in spent fuel pools, reducing risks of leaks, corrosion, and heat buildup.

Decay heat management

Spent fuel pools utilize water for efficient decay heat removal through convection and conduction, while Independent Spent Fuel Storage Installations (ISFSIs) rely on passive air cooling systems designed for long-term decay heat dissipation.

Radiological shielding

Spent fuel pools provide continuous water-based radiological shielding for spent nuclear fuel, whereas Independent Spent Fuel Storage Installations (ISFSIs) rely on engineered dry cask systems with thick concrete and metal layers to ensure effective radiological shielding during long-term storage.

Pool-to-ISFSI transfer

Spent fuel pool-to-ISFSI transfer involves safely moving cooled spent nuclear fuel from underwater storage in pools to dry cask storage systems at independent spent fuel storage installations, optimizing long-term radiological containment and structural integrity.

Fuel assembly racks

Fuel assembly racks in spent fuel pools provide underwater storage with neutron-absorbing materials for cooling and radiation shielding, whereas ISFSI racks use dry casks with robust structural support and passive cooling mechanisms for long-term, aboveground storage.

Heat exchanger

Spent fuel pools rely on heat exchangers integrated into active cooling systems to remove decay heat from stored nuclear fuel, while Independent Spent Fuel Storage Installations (ISFSIs) use passive air-cooled heat exchangers or dry cask systems designed for long-term, low-maintenance heat dissipation.

Concrete overpack

Concrete overpacks in Independent Spent Fuel Storage Installations (ISFSIs) provide robust radiation shielding and structural protection for spent fuel assemblies, whereas spent fuel pools rely on water for cooling and moderate radiation containment without heavy overpack structures.

Passive cooling

Spent fuel pools rely on active cooling systems with water circulation to remove decay heat, while independent spent fuel storage installations (ISFSIs) utilize passive cooling methods such as natural convection and radiation to safely dissipate heat without mechanical assistance.

Site-independent licensing

Site-independent licensing enables ISFSIs to operate safely without being tied to the reactor site, unlike spent fuel pools which require onsite reactor infrastructure and licensing.

spent fuel pool vs independent spent fuel storage installation (ISFSI) Infographic

njnir.com

njnir.com