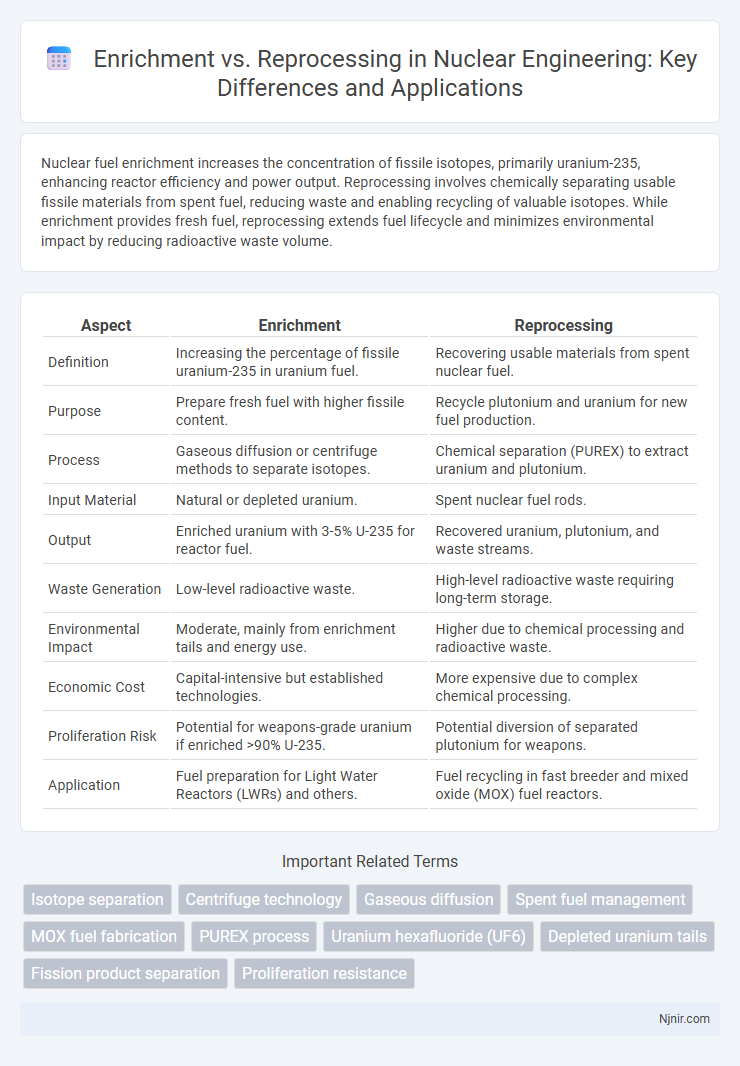

Nuclear fuel enrichment increases the concentration of fissile isotopes, primarily uranium-235, enhancing reactor efficiency and power output. Reprocessing involves chemically separating usable fissile materials from spent fuel, reducing waste and enabling recycling of valuable isotopes. While enrichment provides fresh fuel, reprocessing extends fuel lifecycle and minimizes environmental impact by reducing radioactive waste volume.

Table of Comparison

| Aspect | Enrichment | Reprocessing |

|---|---|---|

| Definition | Increasing the percentage of fissile uranium-235 in uranium fuel. | Recovering usable materials from spent nuclear fuel. |

| Purpose | Prepare fresh fuel with higher fissile content. | Recycle plutonium and uranium for new fuel production. |

| Process | Gaseous diffusion or centrifuge methods to separate isotopes. | Chemical separation (PUREX) to extract uranium and plutonium. |

| Input Material | Natural or depleted uranium. | Spent nuclear fuel rods. |

| Output | Enriched uranium with 3-5% U-235 for reactor fuel. | Recovered uranium, plutonium, and waste streams. |

| Waste Generation | Low-level radioactive waste. | High-level radioactive waste requiring long-term storage. |

| Environmental Impact | Moderate, mainly from enrichment tails and energy use. | Higher due to chemical processing and radioactive waste. |

| Economic Cost | Capital-intensive but established technologies. | More expensive due to complex chemical processing. |

| Proliferation Risk | Potential for weapons-grade uranium if enriched >90% U-235. | Potential diversion of separated plutonium for weapons. |

| Application | Fuel preparation for Light Water Reactors (LWRs) and others. | Fuel recycling in fast breeder and mixed oxide (MOX) fuel reactors. |

Introduction to Uranium Enrichment and Reprocessing

Uranium enrichment increases the concentration of the U-235 isotope to produce fuel suitable for nuclear reactors or weapons, typically raising it from natural levels of 0.7% to 3-5% for reactors. Reprocessing involves chemically separating usable fissile materials, such as uranium and plutonium, from spent nuclear fuel to recycle materials and reduce radioactive waste. Both processes play crucial roles in the nuclear fuel cycle, influencing fuel sustainability, waste management, and non-proliferation considerations.

Fundamental Concepts: Fissionable Materials

Enrichment increases the concentration of fissile isotopes, such as uranium-235, enhancing the fuel's ability to sustain a nuclear chain reaction, while reprocessing recovers usable fissile materials from spent reactor fuel, reducing radioactive waste and enabling fuel recycling. Fissionable materials like uranium-233, uranium-235, and plutonium-239 are essential in both processes to maintain reactor efficiency and nuclear weapon production. Understanding the balance between enrichment levels and reprocessing methods is crucial for optimizing fuel cycles and managing nuclear material safeguards.

Enrichment Technologies: Methods and Applications

Enrichment technologies primarily involve processes like gas centrifugation, gaseous diffusion, and laser isotope separation to increase the concentration of uranium-235 for nuclear fuel. These methods are critical for producing enriched uranium used in nuclear reactors and medical isotopes, enhancing efficiency and purity. Advances in laser enrichment provide higher precision and lower energy consumption compared to traditional techniques, making them increasingly important in modern nuclear fuel cycles.

Reprocessing Techniques: Chemical Separation Explained

Reprocessing techniques in nuclear fuel cycles primarily involve chemical separation methods to extract usable fissile materials like uranium and plutonium from spent nuclear fuel. Chemical separation processes such as PUREX (Plutonium Uranium Redox EXtraction) utilize solvent extraction and nitric acid to efficiently isolate these elements, enabling their reuse as reactor fuel. These techniques reduce nuclear waste volume and support sustainable fuel management by recovering valuable isotopes for further energy production.

Comparative Analysis: Enrichment vs Reprocessing

Enrichment increases the concentration of fissile isotopes like uranium-235 to produce fuel for nuclear reactors, optimizing energy output by enhancing fuel efficiency. Reprocessing involves chemically separating usable fissile materials, such as plutonium and uranium, from spent nuclear fuel to recycle them for new fuel fabrication, reducing nuclear waste. While enrichment focuses on initial fuel preparation, reprocessing extends fuel lifecycle and mitigates radioactive waste, both critical for sustainable nuclear fuel management.

Proliferation Risks and Safeguards

Uranium enrichment increases the concentration of U-235 isotope suitable for reactor fuel but raises proliferation risks by potentially enabling the production of weapons-grade material; strict safeguards including IAEA monitoring and containment measures mitigate these risks. Reprocessing separates plutonium from spent nuclear fuel, which can be reused in reactors but also poses proliferation concerns due to the availability of separated plutonium for nuclear weapons. Comprehensive safeguards such as isotopic analysis, surveillance, and physical security are essential to manage and reduce proliferation threats in both enrichment and reprocessing activities.

Waste Management and Environmental Impact

Enrichment and reprocessing serve distinct roles in nuclear fuel management, with enrichment increasing uranium-235 concentration for reactor use, which generates less high-level radioactive waste compared to reprocessing. Reprocessing involves chemically separating usable fissile materials from spent fuel, significantly reducing waste volume but producing complex secondary waste streams requiring advanced treatment. Waste management strategies must prioritize minimizing environmental impact by optimizing containment, recycling usable materials, and employing long-term storage solutions for remaining radioactive byproducts.

Economic Considerations and Market Dynamics

Enrichment involves increasing the concentration of fissile isotopes in uranium, requiring significant capital investment in advanced centrifuge technology but offering scalability for nuclear fuel supply. Reprocessing recovers usable materials like plutonium and uranium from spent fuel, reducing raw material demand and radioactive waste, yet entails high operational costs and complex regulatory challenges. Market dynamics favor enrichment due to established infrastructure and international trade agreements, while reprocessing remains economically viable primarily in countries with closed fuel cycle policies and high uranium prices.

Policy, Regulation, and International Perspectives

Enrichment and reprocessing of nuclear materials are tightly regulated under international treaties such as the Non-Proliferation Treaty (NPT) and governed by the International Atomic Energy Agency (IAEA) safeguards to prevent the spread of nuclear weapons. National policies often differentiate enrichment, which increases uranium-235 concentration, from reprocessing, which separates plutonium from spent fuel, with stricter controls on reprocessing due to proliferation risks. International perspectives emphasize transparency, monitoring, and standardized regulations to balance peaceful nuclear energy use against the threat of nuclear weapon development.

Future Directions in Nuclear Fuel Cycle Strategies

Future directions in nuclear fuel cycle strategies emphasize advanced enrichment technologies that enhance uranium-235 concentration efficiency and reduce tails assays, improving resource utilization. Reprocessing innovations focus on minimizing radioactive waste by recovering plutonium and uranium from spent fuel, supporting closed fuel cycles and sustainability. Integration of enrichment and reprocessing within advanced reactor designs aims to optimize fissile material use, reduce proliferation risk, and enable long-term nuclear energy sustainability.

Isotope separation

Isotope separation in enrichment increases the concentration of fissile material like U-235, while reprocessing chemically extracts usable isotopes from spent nuclear fuel for recycling.

Centrifuge technology

Centrifuge technology enables precise uranium enrichment by separating isotopes based on mass differences, whereas reprocessing involves chemically recovering fissile materials from spent nuclear fuel.

Gaseous diffusion

Gaseous diffusion enriches uranium by separating isotopes based on molecular velocity differences, while reprocessing chemically extracts usable fissile materials from spent nuclear fuel.

Spent fuel management

Spent fuel management prioritizes enrichment to reduce initial uranium use while reprocessing recovers valuable fissile materials from spent fuel to minimize nuclear waste volume and extend fuel resources.

MOX fuel fabrication

MOX fuel fabrication relies on plutonium extracted through reprocessing spent nuclear fuel, whereas enrichment increases uranium-235 concentration but is not used to produce plutonium-based MOX fuel.

PUREX process

PUREX process enhances uranium enrichment by separating plutonium and uranium from spent nuclear fuel through solvent extraction techniques rather than reprocessing the entire fuel.

Uranium hexafluoride (UF6)

Uranium hexafluoride (UF6) is enriched by increasing the concentration of U-235 isotopes, while reprocessing involves chemically separating usable uranium and plutonium from spent nuclear fuel.

Depleted uranium tails

Depleted uranium tails, primarily composed of uranium-238, accumulate during the enrichment process and require specialized reprocessing techniques to recover residual fissile material and reduce nuclear waste.

Fission product separation

Fission product separation in enrichment enhances uranium isotope concentration by removing unwanted isotopes, while reprocessing involves chemical extraction of fission products from spent nuclear fuel to recycle usable materials and reduce radioactive waste.

Proliferation resistance

Enrichment increases proliferation risks by producing weapons-grade material, whereas reprocessing poses higher proliferation resistance due to incorporating isotopic dilution and complex chemical steps.

enrichment vs reprocessing Infographic

njnir.com

njnir.com