Spent fuel reprocessing recovers valuable materials like plutonium and uranium for reuse in reactors, reducing the volume and radiotoxicity of high-level waste. Direct disposal involves sealing spent fuel in engineered repositories without separation, relying on long-term containment and geological isolation. Reprocessing presents economic and proliferation challenges, while direct disposal offers simpler waste management but requires robust geological sites to ensure safety.

Table of Comparison

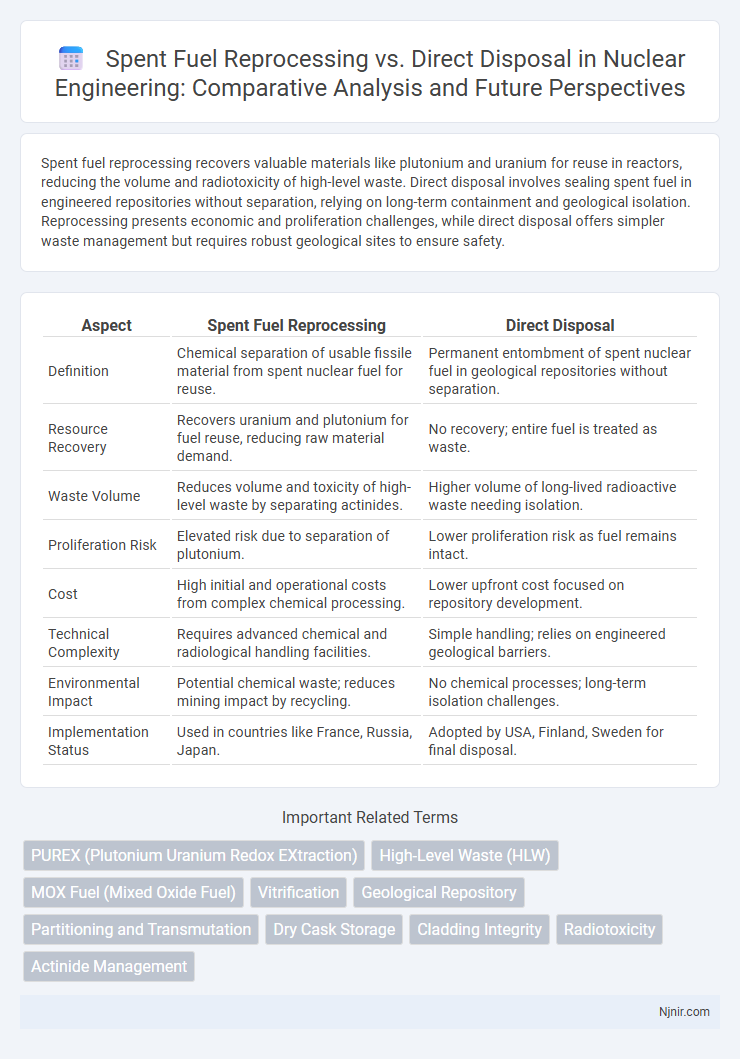

| Aspect | Spent Fuel Reprocessing | Direct Disposal |

|---|---|---|

| Definition | Chemical separation of usable fissile material from spent nuclear fuel for reuse. | Permanent entombment of spent nuclear fuel in geological repositories without separation. |

| Resource Recovery | Recovers uranium and plutonium for fuel reuse, reducing raw material demand. | No recovery; entire fuel is treated as waste. |

| Waste Volume | Reduces volume and toxicity of high-level waste by separating actinides. | Higher volume of long-lived radioactive waste needing isolation. |

| Proliferation Risk | Elevated risk due to separation of plutonium. | Lower proliferation risk as fuel remains intact. |

| Cost | High initial and operational costs from complex chemical processing. | Lower upfront cost focused on repository development. |

| Technical Complexity | Requires advanced chemical and radiological handling facilities. | Simple handling; relies on engineered geological barriers. |

| Environmental Impact | Potential chemical waste; reduces mining impact by recycling. | No chemical processes; long-term isolation challenges. |

| Implementation Status | Used in countries like France, Russia, Japan. | Adopted by USA, Finland, Sweden for final disposal. |

Overview of Spent Nuclear Fuel Management

Spent nuclear fuel management involves two primary approaches: spent fuel reprocessing and direct disposal. Spent fuel reprocessing extracts usable materials like uranium and plutonium for recycling into new fuel, reducing waste volume and radiotoxicity. In contrast, direct disposal entails securing spent fuel in deep geological repositories without separation, prioritizing containment and isolation to ensure long-term environmental safety.

Introduction to Spent Fuel Reprocessing

Spent fuel reprocessing involves chemically separating usable fissile materials like uranium and plutonium from spent nuclear fuel, enabling their reuse in reactors and reducing the volume and toxicity of high-level radioactive waste. This process contrasts with direct disposal, which entails permanently storing spent fuel without extracting valuable materials, leading to larger waste volumes and longer isolation periods. Reprocessing enhances resource efficiency and waste management strategies within the nuclear fuel cycle.

Direct Disposal: Principles and Practices

Direct disposal of spent nuclear fuel involves safely isolating radioactive waste in deep geological repositories, minimizing environmental impact without altering the fuel's chemical composition. This approach emphasizes stable host rock formations, engineered barriers, and long-term monitoring to ensure containment over thousands of years. Principles focus on passive safety, robust containment, and minimizing human intervention, making direct disposal a widely accepted practice in nuclear waste management.

Comparative Environmental Impacts

Spent fuel reprocessing reduces the volume of high-level radioactive waste by recycling usable materials, thereby decreasing the long-term storage burden and potential environmental contamination. Direct disposal involves sealing spent fuel in geological repositories, minimizing immediate environmental impacts but requiring long-term monitoring due to persistent radioactivity and heat generation. Reprocessing has higher short-term environmental risks from chemical and radiological emissions, whereas direct disposal limits these risks but demands robust barrier systems to prevent groundwater contamination over millennia.

Safety and Security Considerations

Spent fuel reprocessing reduces the volume and radiotoxicity of high-level waste, enhancing long-term safety by enabling recycling of usable materials while minimizing environmental contamination risks. Direct disposal involves sealing spent fuel in engineered geological repositories, relying on stable geologic formations to isolate radioactivity, thus simplifying security concerns by avoiding separation of fissile materials. Both methods require stringent safeguards to prevent unauthorized access, with reprocessing necessitating advanced proliferation resistance measures due to material separation activities.

Economic Analysis: Cost and Resource Efficiency

Spent fuel reprocessing involves higher upfront capital expenditure but can recover valuable fissile materials, reducing the need for fresh uranium mining and decreasing long-term fuel costs. Direct disposal offers lower initial costs and simpler infrastructure, yet requires extensive geological repositories and faces escalating expenses for waste monitoring and retrievable storage over centuries. Economic analysis favors reprocessing in resource-scarce contexts due to material recovery and reduced fresh fuel demand, while direct disposal remains cost-effective where disposal sites are secure and uranium resources are abundant.

Waste Volume and Radioactive Inventory Reduction

Spent fuel reprocessing significantly reduces waste volume by separating usable fissile materials from high-level radioactive waste, allowing for the recycling of uranium and plutonium while condensing the remaining waste into a smaller, more manageable form. This process decreases the radioactive inventory and heat load of the final waste, easing storage and disposal challenges compared to direct disposal, which involves encapsulating entire spent fuel assemblies without volume reduction. Direct disposal results in larger waste volumes with higher long-lived radioactive isotopes, requiring more extensive geological repository capacity for long-term isolation.

Technological Challenges and Innovations

Spent fuel reprocessing faces technological challenges including complex chemical separation processes, managing high-level radioactive waste, and ensuring proliferation resistance, driving innovations such as advanced solvent extraction and pyroprocessing techniques. Direct disposal requires robust containment materials and long-term geological stability, prompting development of multi-barrier repository designs and real-time monitoring technologies. Innovations in both approaches aim to enhance safety, reduce environmental impact, and improve resource recovery efficiency.

Regulatory Frameworks and International Approaches

Spent fuel reprocessing and direct disposal operate under distinct regulatory frameworks shaped by national policies and international guidelines from organizations such as the International Atomic Energy Agency (IAEA). Countries employing reprocessing, like France and Japan, enforce stringent safety and environmental regulations to manage radioactive waste recycling, while direct disposal strategies adopted by nations like the United States emphasize long-term geological isolation under rigorous licensing requirements. International approaches balance non-proliferation concerns, environmental protection, and sustainable resource utilization, influencing regulatory standards for both methods globally.

Future Outlook: Sustainability and Policy Directions

Spent fuel reprocessing advances sustainability by recovering valuable materials like uranium and plutonium, reducing nuclear waste volume and enabling resource reuse in new fuel production. Direct disposal remains the predominant strategy due to lower immediate costs and simpler infrastructure requirements but raises long-term environmental and security concerns. Emerging policy trends emphasize integrating reprocessing technologies with enhanced waste management frameworks to balance economic viability, environmental safety, and energy security goals.

PUREX (Plutonium Uranium Redox EXtraction)

PUREX, the dominant spent fuel reprocessing method, chemically separates plutonium and uranium from spent nuclear fuel for reuse, enhancing resource efficiency and waste volume reduction compared to direct disposal that permanently isolates spent fuel without material recovery.

High-Level Waste (HLW)

Spent fuel reprocessing reduces the volume and radiotoxicity of high-level waste (HLW) by separating usable materials, whereas direct disposal involves immobilizing the entire spent fuel as HLW without separation, impacting long-term storage requirements and environmental risk.

MOX Fuel (Mixed Oxide Fuel)

MOX fuel reprocessing recovers plutonium and uranium from spent nuclear fuel to manufacture new fuel, reducing waste volume and enhancing resource efficiency compared to direct disposal, which permanently stores spent fuel without material reuse.

Vitrification

Vitrification in spent fuel reprocessing immobilizes radioactive waste in stable glass matrices, significantly reducing environmental risks compared to direct disposal methods.

Geological Repository

Spent fuel reprocessing reduces the volume and radiotoxicity of waste, enabling more efficient use of geological repositories compared to the significantly larger and more hazardous waste burden resulting from direct disposal.

Partitioning and Transmutation

Partitioning and transmutation in spent fuel reprocessing reduce long-lived radioactive isotopes, enabling more efficient waste management compared to direct disposal.

Dry Cask Storage

Dry cask storage provides a secure, cost-effective interim solution for spent fuel management in direct disposal, avoiding the complex chemical processing and proliferation risks associated with reprocessing.

Cladding Integrity

Cladding integrity plays a critical role in spent fuel reprocessing by maintaining fuel rod containment and minimizing radioactive release risks, whereas direct disposal relies on cladding as an initial barrier without reprocessing, potentially compromising long-term containment.

Radiotoxicity

Spent fuel reprocessing reduces long-term radiotoxicity by separating and recycling usable materials, whereas direct disposal results in higher radiotoxicity due to the containment of all radioactive isotopes within the waste.

Actinide Management

Spent fuel reprocessing significantly reduces long-lived actinide inventories by recycling plutonium and minor actinides, enhancing actinide management compared to direct disposal which isolates actinides in geological repositories without volume or radiotoxicity reduction.

Spent Fuel Reprocessing vs Direct Disposal Infographic

njnir.com

njnir.com