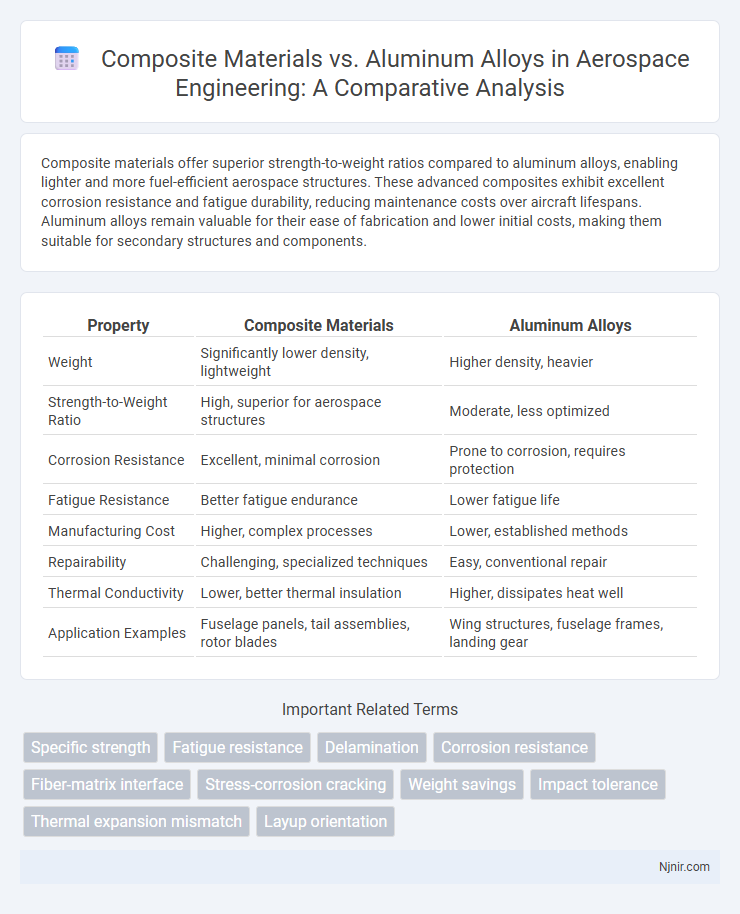

Composite materials offer superior strength-to-weight ratios compared to aluminum alloys, enabling lighter and more fuel-efficient aerospace structures. These advanced composites exhibit excellent corrosion resistance and fatigue durability, reducing maintenance costs over aircraft lifespans. Aluminum alloys remain valuable for their ease of fabrication and lower initial costs, making them suitable for secondary structures and components.

Table of Comparison

| Property | Composite Materials | Aluminum Alloys |

|---|---|---|

| Weight | Significantly lower density, lightweight | Higher density, heavier |

| Strength-to-Weight Ratio | High, superior for aerospace structures | Moderate, less optimized |

| Corrosion Resistance | Excellent, minimal corrosion | Prone to corrosion, requires protection |

| Fatigue Resistance | Better fatigue endurance | Lower fatigue life |

| Manufacturing Cost | Higher, complex processes | Lower, established methods |

| Repairability | Challenging, specialized techniques | Easy, conventional repair |

| Thermal Conductivity | Lower, better thermal insulation | Higher, dissipates heat well |

| Application Examples | Fuselage panels, tail assemblies, rotor blades | Wing structures, fuselage frames, landing gear |

Introduction to Aerospace Structural Materials

Composite materials in aerospace structures offer superior strength-to-weight ratios compared to traditional aluminum alloys, enabling significant weight reduction and fuel efficiency improvements. Aluminum alloys have historically been favored for their excellent corrosion resistance, ease of fabrication, and cost-effectiveness, but composites provide enhanced fatigue resistance and design flexibility. Advances in carbon fiber-reinforced polymers and other composites have driven their increasing adoption in critical aerospace components, transforming structural design paradigms.

Historical Usage: Aluminum Alloys in Aerospace

Aluminum alloys have played a pivotal role in aerospace history since the early 20th century, prized for their lightweight properties and high strength-to-weight ratio. Early aircraft extensively utilized aluminum alloys such as 2024 and 7075, enabling enhanced performance and fuel efficiency during World War II and beyond. The transition to composite materials began primarily in the late 20th century, as advanced composites offered superior corrosion resistance and tailored mechanical properties for modern aerospace applications.

Emergence and Evolution of Composite Materials

Composite materials have emerged as advanced alternatives to aluminum alloys due to their superior strength-to-weight ratio, corrosion resistance, and design flexibility. The evolution of composite materials began in the mid-20th century with the development of fiber-reinforced polymers such as carbon fiber and fiberglass, which transformed aerospace, automotive, and construction industries. Continuous innovations in resin chemistry and fiber technology have further expanded the applications of composites, making them increasingly preferred over traditional aluminum alloys in high-performance environments.

Mechanical Properties: Strength-to-Weight Ratio Comparison

Composite materials exhibit a superior strength-to-weight ratio compared to aluminum alloys, making them ideal for aerospace and automotive applications where weight reduction is critical. High-performance composites such as carbon fiber reinforced polymers provide tensile strengths exceeding 1,500 MPa with densities as low as 1.6 g/cm3, outperforming common aluminum alloys like 7075-T6 which offer tensile strengths around 570 MPa at 2.8 g/cm3 density. This enhanced mechanical efficiency enables structural designs with improved load-bearing capacity while minimizing overall mass.

Corrosion Resistance and Durability

Composite materials outperform aluminum alloys in corrosion resistance due to their non-metallic composition, which inherently resists oxidation and chemical degradation. Aluminum alloys, while lightweight and strong, are susceptible to corrosion, particularly in marine and industrial environments, requiring protective coatings to enhance durability. Consequently, composites offer superior longevity and reduced maintenance costs in harsh conditions, making them ideal for aerospace and automotive applications where corrosion resistance is critical.

Manufacturing and Fabrication Processes

Composite materials are manufactured using processes such as lay-up, resin transfer molding, and filament winding, which allow precise control over fiber orientation and resin content to optimize strength-to-weight ratios. Aluminum alloys are fabricated through extrusion, rolling, forging, and casting, providing high ductility and ease of machining for complex shapes. The choice between composites and aluminum alloys depends on the required mechanical properties, production volume, and cost-effectiveness of the manufacturing process.

Cost Analysis: Initial Investment vs Lifecycle Expenses

Composite materials often require a higher initial investment due to expensive raw materials and complex manufacturing processes, while aluminum alloys generally offer lower upfront costs with well-established fabrication methods. Over the lifecycle, composites provide cost savings through improved corrosion resistance, reduced maintenance, and longer service life, potentially offsetting their initial expense. Aluminum alloys may incur higher lifecycle costs related to frequent repairs, corrosion protection, and shorter durability, impacting total cost of ownership.

Impact on Aircraft Design and Performance

Composite materials significantly reduce aircraft weight compared to aluminum alloys, enhancing fuel efficiency and increasing payload capacity. Their superior corrosion resistance and fatigue strength contribute to lower maintenance costs and longer service life. The ability to tailor composite layups enables optimized aerodynamic shapes, improving overall aircraft performance and design flexibility.

Maintenance, Repair, and Sustainability Considerations

Composite materials require specialized maintenance protocols to prevent fiber damage and matrix degradation, often involving non-destructive testing techniques, while aluminum alloys allow easier visual inspections and simpler repair methods like welding or patching. Repair of composites can be labor-intensive and demands skilled technicians for effective restoration, contrasting with the generally faster and more cost-effective repair processes for aluminum alloys. From a sustainability perspective, composites pose recycling challenges due to their complex material makeup, whereas aluminum alloys benefit from well-established recycling systems, enhancing their environmental appeal in long-term use.

Future Trends in Aerospace Material Development

Composite materials are increasingly favored in aerospace for their superior strength-to-weight ratios and corrosion resistance compared to aluminum alloys. Future trends emphasize the integration of advanced carbon fiber-reinforced polymers and hybrid composites to enhance fuel efficiency and structural performance. Innovations in nanomaterial reinforcements and additive manufacturing techniques are set to revolutionize aerospace components, surpassing traditional aluminum alloy applications.

Specific strength

Composite materials exhibit higher specific strength than aluminum alloys due to their superior strength-to-weight ratio and tailored fiber reinforcement.

Fatigue resistance

Composite materials exhibit superior fatigue resistance compared to aluminum alloys due to their enhanced ability to dissipate stress and resist crack propagation under cyclic loading.

Delamination

Composite materials exhibit higher susceptibility to delamination compared to aluminum alloys due to their layered fiber-matrix structure and weaker interlaminar bonding.

Corrosion resistance

Composite materials exhibit superior corrosion resistance compared to aluminum alloys due to their inert matrix and lack of metal components prone to oxidation.

Fiber-matrix interface

The fiber-matrix interface in composite materials crucially enhances load transfer efficiency and damage tolerance compared to the more homogeneous bonding mechanisms in aluminum alloys.

Stress-corrosion cracking

Composite materials exhibit greater resistance to stress-corrosion cracking compared to aluminum alloys, making them more suitable for harsh chemical and marine environments.

Weight savings

Composite materials offer up to 50% greater weight savings compared to aluminum alloys, enhancing fuel efficiency and performance in aerospace and automotive applications.

Impact tolerance

Composite materials exhibit higher impact tolerance than aluminum alloys due to their superior energy absorption and damage resistance properties.

Thermal expansion mismatch

Composite materials exhibit significantly lower thermal expansion mismatch compared to aluminum alloys, enhancing dimensional stability under temperature variations.

Layup orientation

Layup orientation in composite materials significantly influences mechanical properties and weight optimization compared to aluminum alloys, which rely on uniform isotropic behavior.

composite materials vs aluminum alloys Infographic

njnir.com

njnir.com