Swirl injectors create a rotating flow of fuel to enhance atomization and promote efficient combustion, making them ideal for high-performance rocket engines. Pintle injectors offer adjustable flow rates and improved throttling capabilities, enabling precise thrust control and minimizing combustion instability. Both injector types optimize fuel-air mixing but differ in complexity and operational flexibility within aerospace propulsion systems.

Table of Comparison

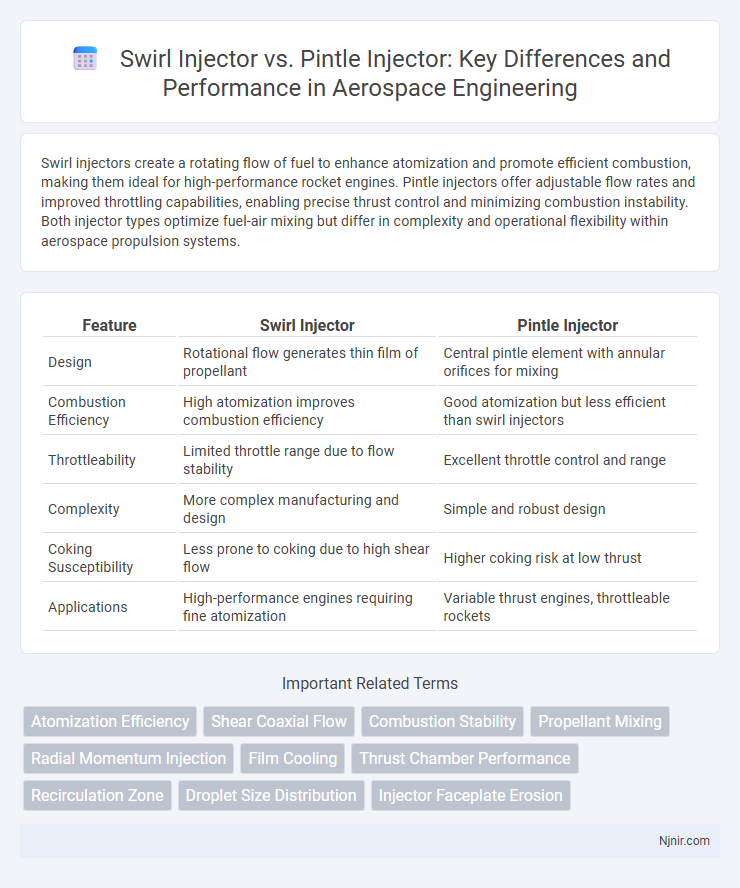

| Feature | Swirl Injector | Pintle Injector |

|---|---|---|

| Design | Rotational flow generates thin film of propellant | Central pintle element with annular orifices for mixing |

| Combustion Efficiency | High atomization improves combustion efficiency | Good atomization but less efficient than swirl injectors |

| Throttleability | Limited throttle range due to flow stability | Excellent throttle control and range |

| Complexity | More complex manufacturing and design | Simple and robust design |

| Coking Susceptibility | Less prone to coking due to high shear flow | Higher coking risk at low thrust |

| Applications | High-performance engines requiring fine atomization | Variable thrust engines, throttleable rockets |

Introduction to Liquid Rocket Injectors

Liquid rocket injectors play a crucial role in mixing fuel and oxidizer to ensure efficient combustion within rocket engines. Swirl injectors create a rotating flow that enhances atomization by imparting tangential velocity to the propellant, improving mixture homogeneity and combustion stability. Pintle injectors use a central pintle to control flow rates and produce well-targeted spray patterns, allowing throttling capabilities and reducing combustion instabilities in variable thrust applications.

Fundamentals of Swirl Injectors

Swirl injectors create a rotating flow pattern by tangentially introducing fuel into the combustion chamber, enhancing atomization and mixing efficiency. The centrifugal force in swirl injectors produces fine fuel droplets, improving combustion stability and reducing emissions compared to pintle injectors. Pintle injectors rely on a central needle to modulate fuel flow, but the fundamental advantage of swirl injectors lies in their superior spray dispersion and combustion performance.

Fundamentals of Pintle Injectors

Pintle injectors feature a central rod that modulates fuel flow through an annular gap, allowing precise control of the spray pattern and atomization essential for efficient combustion. Unlike swirl injectors, which rely on tangential entry to impart rotational motion to the fuel, pintle injectors achieve adjustable spray angles by altering the pintle position, enhancing performance across variable operating conditions. This design minimizes coking and improves thermostability, making pintle injectors advantageous in applications demanding adaptable thrust and combustion stability.

Design Principles and Mechanisms

Swirl injectors operate by imparting a rotational motion to the fuel, creating a swirling film that enhances atomization and mixing with the oxidizer for efficient combustion. Pintle injectors feature a central pintle that modulates flow and creates a controlled spray pattern, offering superior throttling capability and reduced combustion instability. The design principle of swirl injectors emphasizes maximizing tangential velocity to improve spray quality, while pintle injectors rely on axial displacement of the pintle to adjust flow area and spray characteristics dynamically.

Combustion Efficiency Comparison

Swirl injectors improve combustion efficiency by enhancing fuel-air mixing through centrifugal force, leading to more uniform atomization and faster vaporization. Pintle injectors offer precise flow control with adjustable spray angles, optimizing combustion stability but potentially less effective mixing compared to swirl designs. Experimental data shows swirl injectors can achieve combustion efficiency increases of up to 10% in certain liquid propulsion systems, outperforming pintle injectors under high-thrust conditions.

Atomization and Mixing Performance

Swirl injectors create a high-speed rotational flow that significantly enhances fuel atomization by forming fine droplets, resulting in improved air-fuel mixing and combustion efficiency. Pintle injectors deliver fuel through a central needle, producing a wider spray pattern with moderate atomization suitable for stable combustion under varying loads. The superior atomization and rapid mixing of swirl injectors make them ideal for high-performance engines requiring precise fuel delivery and reduced emissions.

Throttling and Control Capabilities

Swirl injectors provide excellent atomization and mixing but have limited throttling range due to their fixed geometric design, making fine control over flow rates challenging. Pintle injectors offer superior throttling capabilities with a movable pintle that adjusts the orifice size, enabling precise control over propellant flow and combustion stability. This adaptability makes pintle injectors preferred for applications requiring variable thrust and dynamic performance control.

Common Applications in Aerospace

Swirl injectors commonly serve in aerospace applications requiring efficient mixing and stable combustion, such as liquid rocket engines and gas turbine combustors, due to their ability to generate a strong tangential flow and enhance atomization. Pintle injectors are preferred in spacecraft propulsion systems and booster engines for their throttleability and precise control over propellant flow, enabling responsive thrust modulation and reliable operation under varying conditions. Both injector types contribute to optimizing performance and combustion stability in high-performance aerospace propulsion systems.

Advantages and Limitations

Swirl injectors provide enhanced atomization and improved fuel-air mixing by creating a strong rotational flow, which leads to better combustion efficiency and reduced emissions in propulsion systems. Pintle injectors offer superior throttling capability and simpler mechanical design, making them ideal for applications requiring variable thrust and reliable operation under changing conditions. However, swirl injectors may face challenges with manufacturing complexity and sensitivity to flow variations, while pintle injectors can suffer from less uniform fuel distribution and potential combustion instability at high thrust levels.

Future Trends in Injector Technology

Future trends in injector technology emphasize enhanced fuel atomization and precise flow control, driving advancements in both Swirl Injectors and Pintle Injectors. Swirl Injectors leverage vortex formation for uniform mixing, while Pintle Injectors offer variable flow rates and adjustable spray patterns, crucial for next-generation combustion engines. Integration of smart sensors and adaptive control systems is expected to optimize injector performance, reduce emissions, and improve fuel efficiency across automotive and aerospace applications.

Atomization Efficiency

Swirl injectors achieve higher atomization efficiency than pintle injectors by generating strong tangential flow that produces finer droplets and better fuel-air mixing.

Shear Coaxial Flow

Shear coaxial flow in swirl injectors enhances atomization through rotational momentum, while pintle injectors achieve efficient mixing via adjustable needle displacement controlling the fuel flow pattern.

Combustion Stability

Swirl injectors enhance combustion stability by creating a strong rotational flow that promotes thorough fuel-air mixing, while pintle injectors offer adjustable flow patterns but generally provide less stable combustion under varying operating conditions.

Propellant Mixing

Swirl injectors enhance propellant mixing by creating a centrifugal flow that atomizes fuel more uniformly, while pintle injectors achieve mixing through axial jets and radial displacement for controlled combustion stability.

Radial Momentum Injection

Swirl injectors enhance radial momentum injection through tangential flow creating a rotating spray pattern, while pintle injectors deliver radial momentum primarily via axial spray that expands outward around the pintle tip.

Film Cooling

Swirl injectors enhance film cooling efficiency by producing a highly atomized fuel spray that improves film coverage, while pintle injectors offer adjustable spray patterns that optimize localized cooling effectiveness.

Thrust Chamber Performance

Swirl injectors enhance thrust chamber performance by promoting superior fuel-oxidizer mixing and atomization, resulting in more efficient combustion compared to pintle injectors, which offer simpler design and throttling capabilities but with less uniform mixture distribution.

Recirculation Zone

Swirl injectors create a stable recirculation zone that enhances fuel-air mixing and combustion efficiency, whereas pintle injectors produce a less defined recirculation zone leading to different spray patterns and potentially less efficient mixing.

Droplet Size Distribution

Swirl injectors produce a narrower droplet size distribution with smaller, more uniform droplets compared to pintle injectors, which generate a wider range of droplet sizes due to their simpler flow pattern.

Injector Faceplate Erosion

Swirl injectors tend to exhibit lower injector faceplate erosion compared to pintle injectors due to their enhanced atomization and reduced localized thermal stresses.

Swirl Injector vs Pintle Injector Infographic

njnir.com

njnir.com