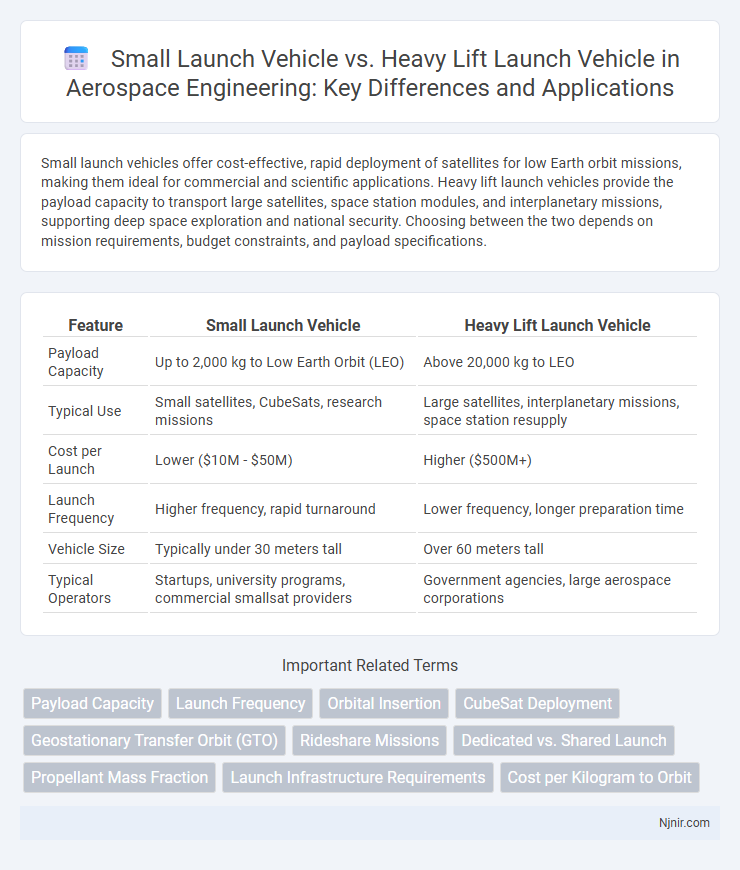

Small launch vehicles offer cost-effective, rapid deployment of satellites for low Earth orbit missions, making them ideal for commercial and scientific applications. Heavy lift launch vehicles provide the payload capacity to transport large satellites, space station modules, and interplanetary missions, supporting deep space exploration and national security. Choosing between the two depends on mission requirements, budget constraints, and payload specifications.

Table of Comparison

| Feature | Small Launch Vehicle | Heavy Lift Launch Vehicle |

|---|---|---|

| Payload Capacity | Up to 2,000 kg to Low Earth Orbit (LEO) | Above 20,000 kg to LEO |

| Typical Use | Small satellites, CubeSats, research missions | Large satellites, interplanetary missions, space station resupply |

| Cost per Launch | Lower ($10M - $50M) | Higher ($500M+) |

| Launch Frequency | Higher frequency, rapid turnaround | Lower frequency, longer preparation time |

| Vehicle Size | Typically under 30 meters tall | Over 60 meters tall |

| Typical Operators | Startups, university programs, commercial smallsat providers | Government agencies, large aerospace corporations |

Introduction to Launch Vehicle Classes

Small launch vehicles are designed for deploying payloads typically under 2,000 kilograms into low Earth orbit (LEO), offering cost-effective access to space for small satellites and CubeSats. Heavy lift launch vehicles can carry payloads exceeding 20,000 kilograms to LEO, enabling large-scale missions including crewed spaceflight, deep-space exploration, and deployment of massive satellite constellations. The distinction between these classes reflects varying mission requirements, payload capacities, and launch costs, impacting the choice of vehicle based on satellite size and orbital destination.

Defining Small vs Heavy Lift Launch Vehicles

Small launch vehicles typically have payload capacities up to 2,000 kilograms to low Earth orbit (LEO), designed for deploying nanosatellites and small spacecraft with rapid turnaround and cost-efficiency. Heavy lift launch vehicles possess payload capacities exceeding 20,000 kilograms to LEO, enabling the transportation of large satellites, interplanetary missions, and deep space exploration components. The distinction hinges on their lifting capability, mission scale, and infrastructure requirements, with small launchers favoring agility and heavy lift systems prioritizing volume and mass.

Historical Evolution of Launch Vehicle Sizes

The historical evolution of launch vehicle sizes reflects advancements in rocket technology and mission requirements, starting with small launch vehicles like the early Vanguard and Juno rockets designed for suborbital and low Earth orbit missions. The growing demand for heavier payloads and interplanetary exploration led to the development of heavy lift launch vehicles such as the Saturn V and Falcon Heavy, capable of delivering tens of tons to orbit. This progression highlights the shift from lightweight, experimental rockets to robust, high-capacity systems critical for deep space missions and large satellite deployments.

Payload Capacity and Mission Profiles

Small launch vehicles typically deliver payloads up to 2,000 kilograms to low Earth orbit, serving missions such as deploying small satellites or CubeSats for Earth observation and communications. Heavy lift launch vehicles support payload capacities exceeding 20,000 kilograms to low Earth orbit, enabling complex missions including large satellite deployments, deep space exploration, and interplanetary probes. Mission profiles for small launch vehicles prioritize cost-effective, rapid access to space, while heavy lift vehicles focus on supporting large-scale scientific, military, or commercial payloads requiring significant mass and volume.

Cost Analysis: Development and Launch

Small launch vehicles generally require lower development costs due to simpler designs and smaller payload capacities, making them cost-effective for frequent, low-mass satellite deployments. Heavy lift launch vehicles involve significantly higher development and manufacturing expenses from advanced engineering, robust propulsion systems, and larger fuel requirements, but they enable the transport of oversized payloads or multiple satellites in a single launch. Per kilogram of payload, small launch vehicles often offer competitive pricing for small satellite operators, whereas heavy lift vehicles achieve cost efficiency through economies of scale on large or multiple payload missions.

Flexibility and Deployment Frequency

Small launch vehicles offer exceptional flexibility with rapid deployment capabilities suited for frequent, low-cost satellite launches, enabling agile responses to market demands. Heavy lift launch vehicles, designed for large payloads, have less frequent launches due to complex integration and higher costs, limiting deployment frequency but providing the capacity for significant, singular missions. The trade-off between these launch vehicle classes centers on balancing payload size with launch cadence and mission adaptability.

Infrastructure and Ground Support Requirements

Small launch vehicles typically require minimal infrastructure and ground support, making them compatible with existing small-scale launch pads and mobile launch platforms. Heavy lift launch vehicles demand extensive ground facilities including reinforced launch pads, powerful fueling systems, and advanced payload integration centers to manage their size and weight. The complexity and cost of infrastructure for heavy lift launches significantly exceed those needed for small launch operations, impacting site selection and operational readiness.

Technology and Propulsion Comparisons

Small launch vehicles utilize compact, efficient engines like electric pumps and solid rocket boosters to optimize cost and flexibility for payloads under 2,000 kilograms, emphasizing rapid manufacturing and launch cadence. Heavy lift launch vehicles employ advanced staged combustion or full-flow oxygen-rich cycles with multiple high-thrust engines, such as RS-25 or RD-170 variants, enabling payload capacities exceeding 20,000 kilograms to low Earth orbit. Propulsion advancements in heavy lift rockets focus on maximizing thrust-to-weight ratios and reusability, whereas small launchers prioritize modularity and simplified engine designs to reduce operational complexity.

Market Demand and Commercial Trends

Small launch vehicles cater to the growing demand for deploying small satellites and constellations quickly and cost-effectively, addressing the surge in CubeSat and nanosatellite markets. Heavy lift launch vehicles serve the expanding needs of large-scale missions including deep space exploration, space station resupply, and deploying mega-constellations, driven by government and commercial space agencies. Current commercial trends indicate a rising preference for small launch vehicles due to lower launch costs and increased launch frequency, while heavy lift vehicles remain crucial for complex payloads requiring substantial lift capacity.

Future Outlook in Launch Vehicle Development

Small launch vehicles are expected to dominate the near-term market due to increasing demand for deploying small satellite constellations and cost-effective access to space. Heavy lift launch vehicles will continue advancing with innovations in reusable technology and higher payload capacities to support deep space exploration and large-scale space infrastructure projects. The future outlook suggests a complementary ecosystem where small launchers handle frequent, agile deployments while heavy lift vehicles enable ambitious scientific and commercial missions.

Payload Capacity

Small launch vehicles typically have a payload capacity under 2,000 kilograms to low Earth orbit (LEO), while heavy lift launch vehicles can deliver payloads exceeding 20,000 kilograms to LEO.

Launch Frequency

Small launch vehicles offer higher launch frequency with quicker turnaround times compared to heavy lift launch vehicles, which have lower launch frequency due to complex preparation and higher costs.

Orbital Insertion

Small launch vehicles achieve orbital insertion with payloads typically under 2,000 kg, while heavy lift launch vehicles can insert payloads exceeding 20,000 kg into orbit, enabling larger and more complex missions.

CubeSat Deployment

Small launch vehicles offer cost-effective, dedicated CubeSat deployment with flexible scheduling, whereas heavy lift launch vehicles provide high-capacity rideshare options but involve longer wait times and higher costs for CubeSat launches.

Geostationary Transfer Orbit (GTO)

Small launch vehicles typically deliver payloads up to 1.5 metric tons to Geostationary Transfer Orbit (GTO), while heavy lift launch vehicles can transport 10 metric tons or more, providing greater payload capacity and flexibility for large communications satellites.

Rideshare Missions

Small launch vehicles offer cost-effective and flexible rideshare missions for deploying multiple small satellites, whereas heavy lift launch vehicles provide larger payload capacity ideal for consolidated, high-mass rideshare deployments in space exploration and commercial applications.

Dedicated vs. Shared Launch

Small launch vehicles offer dedicated launches for specific payloads, while heavy lift launch vehicles typically provide shared launch opportunities to accommodate multiple payloads simultaneously.

Propellant Mass Fraction

Heavy lift launch vehicles typically exhibit a higher propellant mass fraction, often exceeding 85%, compared to small launch vehicles whose propellant mass fraction ranges between 70% and 80%, reflecting their greater fuel requirements to deliver heavier payloads into orbit.

Launch Infrastructure Requirements

Small launch vehicles require minimal launch infrastructure with smaller pads and reduced ground support, while heavy lift launch vehicles demand extensive, robust infrastructure including reinforced launch pads, large fueling facilities, and advanced ground support systems.

Cost per Kilogram to Orbit

Small launch vehicles typically cost between $10,000 to $40,000 per kilogram to orbit, whereas heavy-lift launch vehicles can reduce the cost to approximately $1,000 to $5,000 per kilogram due to economies of scale and higher payload capacities.

Small launch vehicle vs Heavy lift launch vehicle Infographic

njnir.com

njnir.com