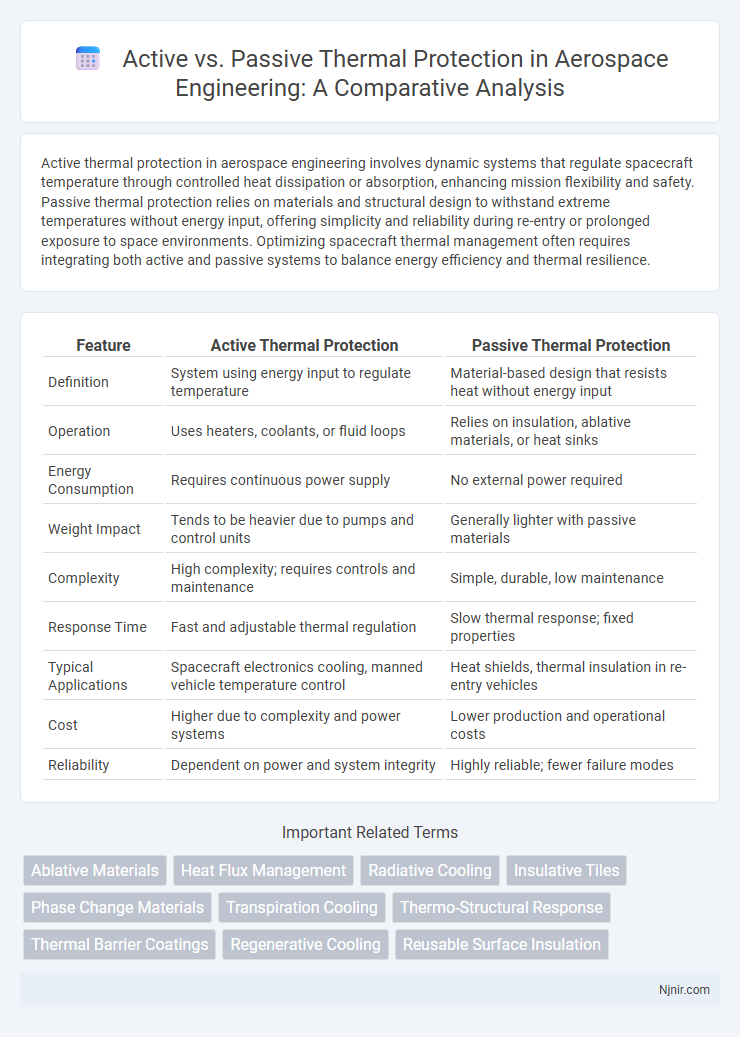

Active thermal protection in aerospace engineering involves dynamic systems that regulate spacecraft temperature through controlled heat dissipation or absorption, enhancing mission flexibility and safety. Passive thermal protection relies on materials and structural design to withstand extreme temperatures without energy input, offering simplicity and reliability during re-entry or prolonged exposure to space environments. Optimizing spacecraft thermal management often requires integrating both active and passive systems to balance energy efficiency and thermal resilience.

Table of Comparison

| Feature | Active Thermal Protection | Passive Thermal Protection |

|---|---|---|

| Definition | System using energy input to regulate temperature | Material-based design that resists heat without energy input |

| Operation | Uses heaters, coolants, or fluid loops | Relies on insulation, ablative materials, or heat sinks |

| Energy Consumption | Requires continuous power supply | No external power required |

| Weight Impact | Tends to be heavier due to pumps and control units | Generally lighter with passive materials |

| Complexity | High complexity; requires controls and maintenance | Simple, durable, low maintenance |

| Response Time | Fast and adjustable thermal regulation | Slow thermal response; fixed properties |

| Typical Applications | Spacecraft electronics cooling, manned vehicle temperature control | Heat shields, thermal insulation in re-entry vehicles |

| Cost | Higher due to complexity and power systems | Lower production and operational costs |

| Reliability | Dependent on power and system integrity | Highly reliable; fewer failure modes |

Introduction to Thermal Protection in Aerospace Engineering

Thermal protection in aerospace engineering involves safeguarding spacecraft and aircraft components from extreme temperature variations encountered during missions. Active thermal protection systems utilize sensors and control mechanisms to regulate temperature dynamically, often involving heating elements or fluid loops to manage heat flow. Passive thermal protection relies on insulating materials, coatings, and heat shields designed to absorb, reflect, or dissipate heat without requiring power or moving parts, ensuring reliability during critical phases like atmospheric re-entry.

Fundamentals of Active and Passive Thermal Protection Systems

Active thermal protection systems regulate heat through mechanical or electrical means, such as fluid circulation or refrigeration units, to maintain desired temperatures in dynamic environments. Passive thermal protection relies on materials with inherent insulating properties or phase-change characteristics, like multi-layer insulation or ablative heat shields, to minimize heat transfer without external energy input. Understanding these fundamentals highlights that active systems provide adaptive temperature control, whereas passive systems offer simplicity and reliability through material design.

Key Materials Used in Passive Thermal Protection

Passive thermal protection relies on materials such as ablative composites, ceramic tiles, and insulating fibrous blankets to withstand extreme heat without active cooling. Ablative composites absorb and dissipate heat through controlled decomposition, while ceramic tiles provide high-temperature resistance and thermal insulation. Fibrous insulation materials like silica or alumina fibers enhance thermal stability by trapping air, reducing heat transfer during re-entry or high-temperature exposure.

Mechanisms and Technologies Behind Active Thermal Protection

Active thermal protection utilizes dynamic cooling mechanisms such as fluid loops, thermoelectric coolers, and phase change materials to regulate temperature by actively removing or redistributing heat. These technologies integrate sensors and control systems that monitor thermal conditions and adjust cooling intensity in real time, optimizing efficiency and protecting sensitive components. In contrast, passive thermal protection relies on materials with high thermal resistance or heat capacity, such as insulative foams or heat sinks, which do not require energy input or active modulation.

Comparative Performance: Active vs Passive Methods

Active thermal protection systems regulate heat through dynamic mechanisms such as fluid circulation or electrical cooling, enabling precise temperature control in high-performance applications like aerospace and electronics. Passive thermal protection relies on insulating materials and structural design to absorb, reflect, or dissipate heat without energy input, offering simplicity and reliability in environments with predictable thermal loads. Comparatively, active methods provide superior adaptability and responsiveness for variable heat conditions, while passive methods excel in durability and energy efficiency during steady-state operations.

Weight, Cost, and Complexity Considerations

Active thermal protection systems typically involve heavier components such as pumps, sensors, and liquid coolant, increasing overall system weight and complexity. Passive thermal protection often relies on lighter materials like insulation or phase-change substances, resulting in lower weight and simpler design but may incur higher upfront material costs. Cost considerations vary as active systems demand more maintenance and energy consumption, while passive systems offer durability with minimal upkeep expenses.

Application Scenarios: When to Use Active or Passive Tactics

Active thermal protection is ideal for dynamic environments where temperature fluctuations occur rapidly, such as in aerospace, electric vehicle battery systems, and high-performance electronics, requiring real-time temperature regulation to prevent overheating. Passive thermal protection suits applications with relatively stable thermal conditions or where maintenance access is limited, including building insulation, outdoor equipment enclosures, and wearable technology, relying on materials like phase-change substances, thermal insulators, or reflective coatings for steady-state heat management. Selecting between active and passive tactics depends on factors like thermal load variability, power availability, system complexity, and maintenance needs within the specific application scenario.

Real-world Examples: Case Studies in Aerospace Missions

Active thermal protection systems, such as those used on the Mars Curiosity rover, employ heaters and coolant loops to regulate temperature dynamically during extreme environmental changes. Passive thermal protection examples include the Apollo Command Module's ablative heat shield, which absorbs and dissipates heat through material composition without mechanical intervention. Case studies show active systems offer precise temperature control in variable conditions, while passive approaches provide reliable, maintenance-free protection during brief, intense thermal events.

Future Trends in Thermal Protection Systems

Future trends in thermal protection systems highlight a shift towards advanced active thermal protection technologies, incorporating smart materials and real-time temperature regulation for enhanced efficiency in extreme environments. Innovations in phase-change materials and adaptive cooling mechanisms are expected to complement passive thermal barriers, providing dynamic responses to varying thermal loads. Research emphasizes integration of nanotechnology and AI-driven monitoring to optimize performance, durability, and energy consumption in aerospace, automotive, and wearable applications.

Conclusions and Recommendations for Design Choices

Active Thermal Protection systems offer precise temperature control through dynamic heat regulation, making them ideal for environments with fluctuating thermal loads. Passive Thermal Protection relies on materials with inherent insulating properties, providing reliable, maintenance-free defense in stable or predictable temperature conditions. Design choices should prioritize active systems for high-performance applications requiring adaptability, while passive systems suit cost-sensitive, low-maintenance scenarios with consistent thermal demands.

Ablative Materials

Ablative materials in active thermal protection systems absorb and dissipate heat through controlled erosion, providing superior protection compared to passive thermal protection that relies on fixed insulation without material consumption.

Heat Flux Management

Active Thermal Protection systems optimize heat flux management through dynamic cooling techniques, whereas Passive Thermal Protection relies on fixed insulating materials to absorb and dissipate heat.

Radiative Cooling

Active thermal protection enhances radiative cooling through dynamic heat dissipation mechanisms, whereas passive thermal protection relies solely on material properties to emit thermal radiation without external energy input.

Insulative Tiles

Insulative tiles in passive thermal protection provide consistent heat resistance without energy consumption, while active thermal protection systems dynamically regulate temperature but rely on power sources and complex mechanisms.

Phase Change Materials

Phase Change Materials in Active Thermal Protection dynamically regulate temperature by absorbing and releasing heat during phase transitions, unlike Passive Thermal Protection which relies solely on insulation without thermal energy storage.

Transpiration Cooling

Transpiration cooling, an active thermal protection method, enhances heat dissipation by actively pumping coolant through porous surfaces, unlike passive thermal protection systems that rely solely on material properties and insulation.

Thermo-Structural Response

Active thermal protection systems dynamically regulate heat flow to optimize thermo-structural response, whereas passive thermal protection relies on material properties and insulation to withstand thermal loads without active control.

Thermal Barrier Coatings

Thermal Barrier Coatings offer passive thermal protection by providing a durable insulating layer that reduces heat transfer and enhances component longevity compared to active thermal protection systems that rely on dynamic cooling mechanisms.

Regenerative Cooling

Regenerative cooling in active thermal protection systems circulates coolant through engine walls to absorb and dissipate heat efficiently, providing superior thermal management compared to passive thermal protection that relies solely on insulating materials.

Reusable Surface Insulation

Reusable Surface Insulation (RSI) utilizes active thermal protection systems that regulate heat through controlled cooling mechanisms, offering superior adaptability compared to passive thermal protection which relies solely on fixed materials to resist temperature extremes.

Active Thermal Protection vs Passive Thermal Protection Infographic

njnir.com

njnir.com