Fly-by-wire systems replace traditional mechanical control with electronic interfaces, enhancing aircraft responsiveness and reducing pilot workload. Direct control relies on physical linkages between the cockpit and control surfaces, offering simplicity but less adaptability to modern flight conditions. Fly-by-wire technology integrates advanced sensors and computers, enabling precise maneuvering, improved safety, and system redundancy not achievable with direct control.

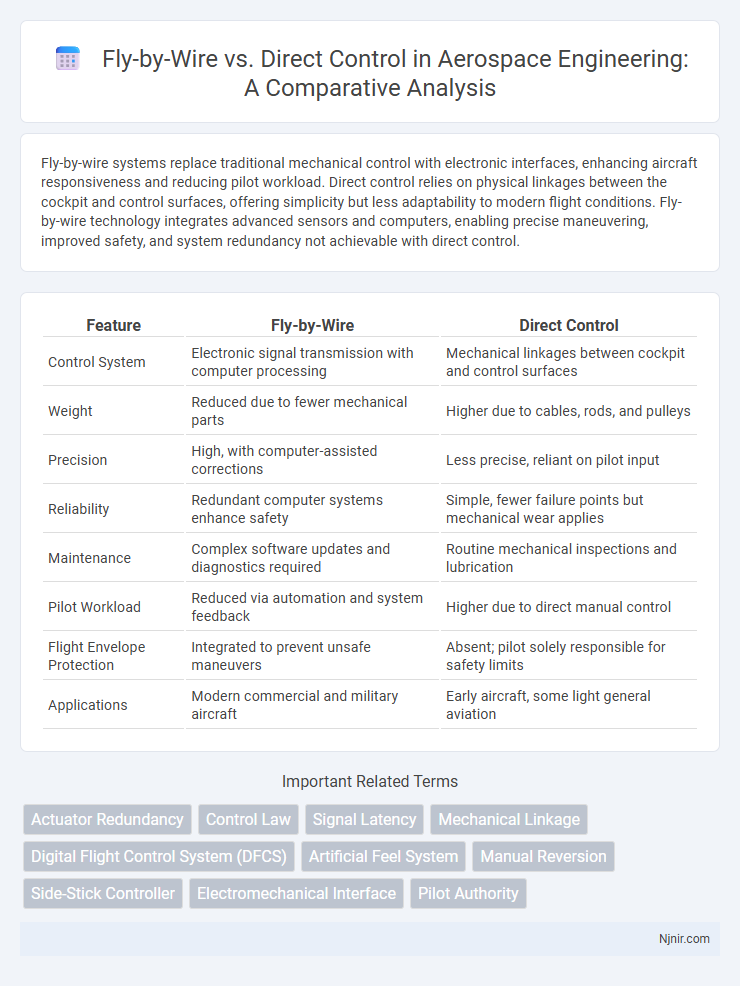

Table of Comparison

| Feature | Fly-by-Wire | Direct Control |

|---|---|---|

| Control System | Electronic signal transmission with computer processing | Mechanical linkages between cockpit and control surfaces |

| Weight | Reduced due to fewer mechanical parts | Higher due to cables, rods, and pulleys |

| Precision | High, with computer-assisted corrections | Less precise, reliant on pilot input |

| Reliability | Redundant computer systems enhance safety | Simple, fewer failure points but mechanical wear applies |

| Maintenance | Complex software updates and diagnostics required | Routine mechanical inspections and lubrication |

| Pilot Workload | Reduced via automation and system feedback | Higher due to direct manual control |

| Flight Envelope Protection | Integrated to prevent unsafe maneuvers | Absent; pilot solely responsible for safety limits |

| Applications | Modern commercial and military aircraft | Early aircraft, some light general aviation |

Introduction to Flight Control Systems

Flight control systems transform pilot inputs into aircraft movements, with fly-by-wire systems replacing traditional mechanical linkages with electronic signals for enhanced precision and safety. Direct control relies on mechanical or hydraulic connections, providing tactile feedback but often increasing weight and maintenance complexity. Fly-by-wire technology integrates sensors, computers, and actuators to optimize flight stability, reduce pilot workload, and enable advanced features like autopilot and envelope protection.

Fundamentals of Direct Control

Direct control in aircraft systems involves a mechanical linkage between the pilot's controls and the control surfaces, enabling immediate and unmediated response to pilot input. Unlike fly-by-wire systems that rely on electronic signals and computer intermediaries, direct control provides a tactile feedback loop and inherent simplicity, reducing the risk of system failures due to software or electronic malfunctions. This fundamental approach emphasizes pilot skill and mechanical reliability, making it prevalent in older or smaller aircraft where system weight and complexity are critical factors.

Principles of Fly-By-Wire Technology

Fly-by-wire (FBW) technology replaces traditional mechanical flight controls with electronic interfaces, using sensors, computers, and actuators to transmit pilot inputs digitally. FBW systems enhance aircraft stability and safety by integrating flight control computers that interpret and optimize commands, providing automatic protections against aerodynamic stalls and structural limits. This digital architecture reduces weight and maintenance while allowing for advanced control laws that improve overall flight performance compared to direct mechanical linkages.

Evolution of Aircraft Control Methods

The evolution of aircraft control methods has progressed from direct mechanical linkages to advanced fly-by-wire systems that replace manual controls with electronic signals, enhancing precision and safety. Fly-by-wire technology integrates computer systems to process pilot inputs and automatically adjust flight control surfaces, reducing pilot workload and allowing for more complex aerodynamic designs. Direct control, characterized by cables and rods physically connected to control surfaces, is simpler but limits responsiveness and adaptability compared to the sophisticated fly-by-wire systems used in modern commercial and military aircraft.

Key Differences: Fly-By-Wire vs Direct Control

Fly-by-wire systems replace traditional mechanical flight controls with electronic interfaces, allowing computer-mediated input that enhances aircraft stability and reduces pilot workload. Direct control relies on mechanical linkages between the cockpit and control surfaces, providing immediate tactile feedback but limited adaptability and increased pilot effort. Fly-by-wire offers advanced safety features like automatic stability corrections and envelope protection, whereas direct control depends entirely on pilot skill without automated intervention.

Safety and Redundancy Considerations

Fly-by-wire systems enhance safety through computerized control, enabling multiple redundant channels that detect and correct pilot input errors, reducing the risk of mechanical failure compared to direct control systems. Direct control relies on mechanical linkages, which are simpler but susceptible to physical wear and damage, offering limited redundancy in critical flight control paths. The integration of fault-tolerant architectures in fly-by-wire ensures continuous operation despite component failures, making it the preferred choice for modern commercial and military aircraft safety standards.

Impact on Aircraft Performance and Efficiency

Fly-by-wire systems enhance aircraft performance by precisely managing control inputs through electronic signals, reducing pilot workload and enabling more aerodynamic maneuvers that improve fuel efficiency. Direct control systems rely on mechanical linkages, which can introduce friction and delay, limiting responsiveness and increasing pilot effort, potentially resulting in less optimized flight paths and higher fuel consumption. The integration of fly-by-wire technology allows for advanced flight control algorithms that optimize lift-to-drag ratios, contributing to significant efficiency gains over traditional direct control setups.

Pilot Experience and Human-Machine Interface

Fly-by-wire systems enhance pilot experience by providing electronic flight control inputs that improve aircraft stability, reduce workload, and offer customizable control feedback. Direct control systems rely on mechanical linkages, giving pilots tactile feedback but increasing physical effort and limiting automation integration. Advanced fly-by-wire human-machine interfaces feature intuitive displays and adaptive controls, optimizing situational awareness and reducing pilot fatigue compared to traditional direct control setups.

Maintenance and System Reliability

Fly-by-wire systems reduce maintenance requirements by replacing mechanical linkages with electronic controls, minimizing wear and tear and enabling real-time diagnostics for proactive issue detection. Direct control systems rely on physical connections that demand regular inspections and adjustments due to mechanical stress and potential component fatigue. The enhanced system reliability of fly-by-wire technology improves overall aircraft safety by integrating redundancy and fault-tolerant features that are less prone to mechanical failure compared to traditional direct control methods.

Future Trends in Aircraft Control Systems

Future trends in aircraft control systems emphasize increased integration of fly-by-wire technology with advanced automation and artificial intelligence to enhance safety, efficiency, and responsiveness. Direct control systems are gradually being supplemented or replaced by adaptive fly-by-wire interfaces that allow real-time system adjustments based on pilot inputs and environmental data. Continued development in sensor fusion, machine learning algorithms, and cybersecurity measures will drive the evolution of aircraft control towards more intelligent, resilient, and autonomous systems.

Actuator Redundancy

Fly-by-wire systems enhance actuator redundancy by employing multiple independent electronic channels to ensure reliable control, whereas direct control systems rely on mechanical linkages with limited redundancy options.

Control Law

Fly-by-wire systems use computerized control laws to interpret pilot inputs and adjust aircraft control surfaces electronically, whereas direct control relies on mechanical linkages transmitting pilot commands without computational enhancement.

Signal Latency

Fly-by-wire systems significantly reduce signal latency compared to direct control by electronically transmitting pilot inputs through digital computers, enhancing aircraft responsiveness and precision.

Mechanical Linkage

Fly-by-wire replaces traditional mechanical linkage with electronic signals for aircraft control, enhancing precision, reducing weight, and increasing system reliability compared to direct mechanical control.

Digital Flight Control System (DFCS)

Digital Flight Control Systems (DFCS) enable fly-by-wire technology by replacing traditional direct control with computer-mediated inputs that optimize aircraft stability, responsiveness, and safety.

Artificial Feel System

The Fly-by-wire system uses an Artificial Feel System to simulate natural control feedback, enhancing pilot input precision compared to the lack of tactile response in Direct control systems.

Manual Reversion

Manual reversion in fly-by-wire systems allows pilots to regain direct control of the aircraft through mechanical linkages when the electronic flight control system fails, contrasting with direct control systems where pilots continuously manipulate control surfaces without electronic intermediaries.

Side-Stick Controller

The Side-Stick Controller in Fly-by-Wire systems enhances pilot precision and safety by electronically transmitting inputs to flight controls, unlike Direct Control where pilot commands mechanically actuate control surfaces.

Electromechanical Interface

Fly-by-wire systems utilize electromechanical interfaces with sensors and actuators to translate pilot inputs into digital signals for flight control computers, whereas direct control relies on mechanical linkages and cables for immediate manual operation.

Pilot Authority

Fly-by-wire systems enhance pilot authority by electronically interpreting control inputs for smoother, more precise maneuvering compared to the direct physical link responsiveness of traditional direct control systems.

Fly-by-wire vs Direct control Infographic

njnir.com

njnir.com