Ablative shielding protects spacecraft by gradually eroding and dissipating heat during reentry, offering reliable thermal protection for single-use missions. Reusable heat shields, made from advanced materials such as reinforced carbon-carbon composites, withstand multiple reentries without significant degradation, reducing long-term costs and increasing mission frequency. Optimizing heat shield design enhances spacecraft safety, thermal efficiency, and sustainability in aerospace engineering.

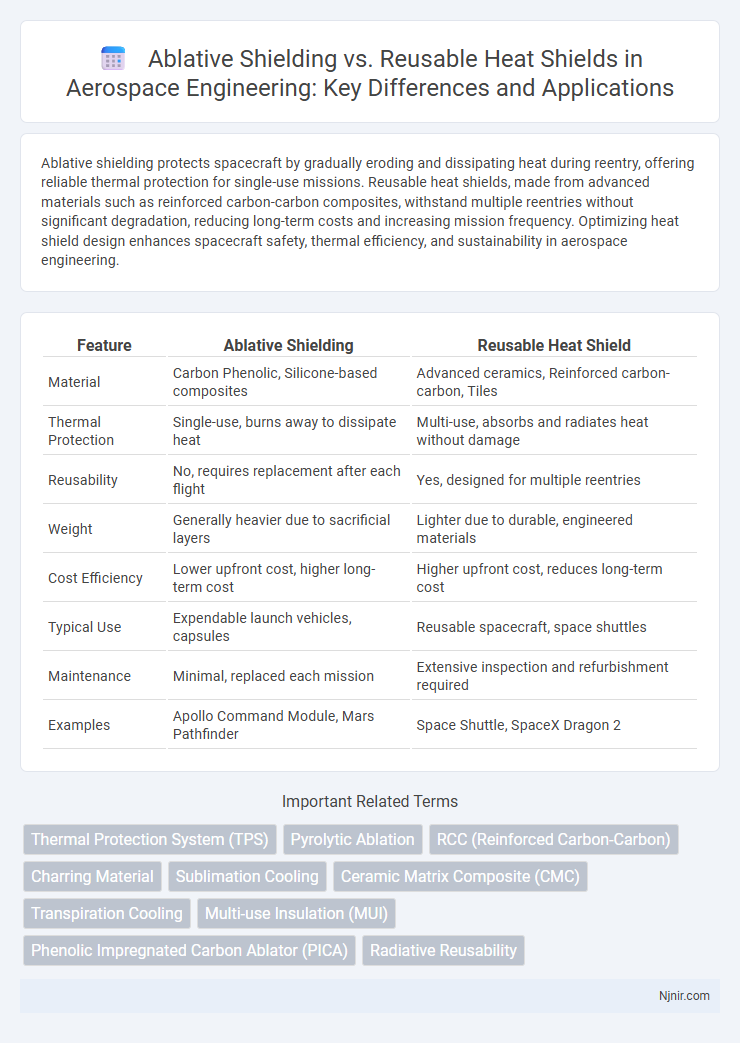

Table of Comparison

| Feature | Ablative Shielding | Reusable Heat Shield |

|---|---|---|

| Material | Carbon Phenolic, Silicone-based composites | Advanced ceramics, Reinforced carbon-carbon, Tiles |

| Thermal Protection | Single-use, burns away to dissipate heat | Multi-use, absorbs and radiates heat without damage |

| Reusability | No, requires replacement after each flight | Yes, designed for multiple reentries |

| Weight | Generally heavier due to sacrificial layers | Lighter due to durable, engineered materials |

| Cost Efficiency | Lower upfront cost, higher long-term cost | Higher upfront cost, reduces long-term cost |

| Typical Use | Expendable launch vehicles, capsules | Reusable spacecraft, space shuttles |

| Maintenance | Minimal, replaced each mission | Extensive inspection and refurbishment required |

| Examples | Apollo Command Module, Mars Pathfinder | Space Shuttle, SpaceX Dragon 2 |

Introduction to Thermal Protection Systems in Aerospace

Thermal protection systems in aerospace utilize ablative shielding by absorbing and dissipating heat through material erosion during reentry, providing reliable protection for single-use spacecraft. Reusable heat shields, constructed from advanced ceramics and insulating materials, maintain structural integrity across multiple missions, enabling cost-effective space exploration. Both systems balance thermal resistance, weight, and durability to safeguard spacecraft from extreme aerodynamic heating in atmospheric reentry environments.

Understanding Ablative Shielding Technologies

Ablative shielding technology protects spacecraft by absorbing and dissipating intense heat through the controlled erosion of its outer layer, effectively managing thermal loads during atmospheric reentry. Unlike reusable heat shields that retain thermal protection for multiple missions, ablative shields are designed for single-use applications, making them cost-effective for expendable missions. Understanding the material properties and erosion mechanics of ablative composites is critical for optimizing heat flux resistance and ensuring spacecraft integrity under extreme reentry conditions.

Fundamentals of Reusable Heat Shield Systems

Reusable heat shield systems utilize advanced materials like reinforced carbon-carbon and silica-based tiles designed to withstand multiple re-entries by managing extreme thermal loads through radiation and conduction mechanisms. Unlike ablative shielding which sacrifices outer layers to dissipate heat via material erosion, reusable shields maintain structural integrity with robust thermal protection coatings and active cooling techniques. Key fundamentals include thermal resistance, mechanical durability, and ease of refurbishment critical for cost-effective spacecraft thermal protection during repeated atmospheric entries.

Key Performance Metrics: Ablative vs. Reusable Shields

Ablative shielding offers superior thermal protection by sacrificing material through controlled erosion, effectively dissipating intense heat during atmospheric reentry, with high heat absorption capacity but limited to single-use applications. Reusable heat shields utilize advanced ceramic or composite materials designed for multiple missions, emphasizing durability and thermal resistance while maintaining structural integrity under cyclic thermal stress. Key performance metrics highlight ablative shields' exceptional peak heat flux tolerance versus reusable shields' cost-efficiency and rapid turnaround enabled by minimal maintenance requirements.

Material Science: Ablative vs. Reusable Heat Shield Materials

Ablative heat shields utilize materials such as phenolic composites that char, melt, and vaporize to dissipate heat through sacrificial erosion, providing superior protection during intense reentry conditions. Reusable heat shields are typically made from high-temperature ceramics or reinforced carbon-carbon composites, designed to withstand multiple thermal cycles without significant material degradation. Advanced material science explores hybrid composites and nanoparticle reinforcements to enhance thermal stability, durability, and weight efficiency in both ablative and reusable heat shield technologies.

Cost Analysis: Manufacturing and Operational Considerations

Ablative shielding involves single-use materials that char and erode during re-entry, resulting in higher manufacturing costs for each mission but lower maintenance expenses, whereas reusable heat shields, such as those made from reinforced carbon-carbon or silica tiles, have higher initial production costs due to complex fabrication and stringent quality control requirements. Operationally, reusable heat shields reduce long-term costs by allowing multiple flights with refurbishment, but require thorough inspection and potential repairs after each mission, increasing downtime and labor expenses. Cost analysis must account for the trade-off between upfront manufacturing investment in reusable systems and the recurring expense of ablative shield replacement, balancing mission frequency and reliability demands.

Maintenance and Turnaround Times

Ablative shielding requires extensive replacement after each use due to material erosion, leading to longer maintenance and turnaround times. Reusable heat shields, made from durable materials like reinforced carbon-carbon or silica tiles, allow for quicker inspections and refurbishment, significantly reducing downtime between missions. Efficient maintenance of reusable shields is critical for operational cost savings and increased flight frequency in space programs.

Applications: Mission Scenarios and Vehicle Compatibility

Ablative shielding excels in single-use mission scenarios such as capsule re-entry from deep space or planetary descent, where intense heat loads require material ablation to dissipate energy effectively. Reusable heat shields, often constructed from high-temperature ceramics or tiles, are preferred for missions involving multiple atmospheric entries, including spaceplanes and orbital vehicles like the Space Shuttle, offering enhanced vehicle compatibility through durability and refurbishment potential. Selecting between ablative and reusable heat shields depends heavily on mission duration, thermal environment, vehicle design constraints, and cost-benefit analyses related to turnaround time and maintenance.

Environmental Impact and Sustainability Perspectives

Ablative shielding, designed to burn away during atmospheric re-entry, generates significant waste and requires extensive material resources for each mission, leading to a higher environmental footprint compared to reusable heat shields. Reusable heat shields, made from durable materials like reinforced carbon-carbon or advanced ceramics, reduce waste and resource consumption by enabling multiple uses, supporting more sustainable spaceflight operations. The shift toward reusable heat shields aligns with growing industry efforts to minimize debris and environmental impact, promoting long-term sustainability in aerospace engineering.

Future Trends in Heat Shield Innovation

Future trends in heat shield innovation emphasize the development of reusable heat shields with advanced materials like ultra-high-temperature ceramics and carbon composites to enhance durability and cost efficiency for multiple reentries. Ablative shielding remains valuable for single-use missions due to its superior ablative properties and lightweight design, particularly in high-performance atmospheric entries. Emerging hybrid solutions integrate both ablative and reusable components, aiming to optimize thermal protection while reducing overall spacecraft mass and turnaround time.

Thermal Protection System (TPS)

Reusable heat shields utilize advanced Thermal Protection Systems (TPS) with durable materials like reinforced carbon-carbon and ceramic tiles to withstand multiple reentries, while ablative shielding relies on sacrificial TPS materials that erode to dissipate heat during a single atmospheric entry.

Pyrolytic Ablation

Pyrolytic ablation in ablative shielding offers superior thermal protection by char-forming and eroding to dissipate heat, unlike reusable heat shields that rely on insulation materials to withstand high reentry temperatures without material loss.

RCC (Reinforced Carbon-Carbon)

Reinforced Carbon-Carbon (RCC) provides superior thermal protection for reusable heat shields by withstanding extreme reentry temperatures and enabling multiple spacecraft missions, unlike ablative shielding which erodes after a single use.

Charring Material

Charring ablative materials provide superior thermal protection by sacrificially absorbing and dissipating heat during atmospheric reentry, contrasting with reusable heat shields that rely on insulating ceramics or tiles to withstand multiple uses without degradation.

Sublimation Cooling

Sublimation cooling in ablative shielding offers efficient heat absorption by phase-change material loss, providing better thermal protection for one-time reentry compared to reusable heat shields relying on surface heat resistance.

Ceramic Matrix Composite (CMC)

Ceramic Matrix Composite (CMC) reusable heat shields offer enhanced thermal durability and structural integrity compared to traditional ablative shielding by enabling multiple reentries without material erosion or replacement.

Transpiration Cooling

Transpiration cooling in reusable heat shields offers superior thermal protection and material longevity compared to single-use ablative shielding by continuously releasing coolant through porous surfaces to absorb heat during high-temperature atmospheric reentry.

Multi-use Insulation (MUI)

Multi-use Insulation (MUI) enables reusable heat shields to withstand multiple reentries by maintaining thermal protection, contrasting with single-use ablative shielding that sacrifices material during each atmospheric entry.

Phenolic Impregnated Carbon Ablator (PICA)

Phenolic Impregnated Carbon Ablator (PICA) offers lightweight, high-performance ablative shielding ideal for single-use spacecraft reentry, while reusable heat shields prioritize durability and thermal protection through materials capable of withstanding multiple entries.

Radiative Reusability

Reusable heat shields offer superior radiative reusability by withstanding multiple high-temperature reentries through durable materials that efficiently radiate heat, unlike ablative shielding which sacrifices material during each use.

ablative shielding vs reusable heat shield Infographic

njnir.com

njnir.com