Boundary layer control techniques enhance aerodynamic efficiency by manipulating airflow to delay separation and reduce drag, whereas vortex generators create small, controlled vortices that energize the boundary layer and prevent flow separation. Both methods improve aircraft performance by maintaining smooth airflow over control surfaces, but vortex generators are particularly effective at low speeds or high angles of attack. Implementing these strategies optimizes lift-to-drag ratio and fuel efficiency in aerospace applications.

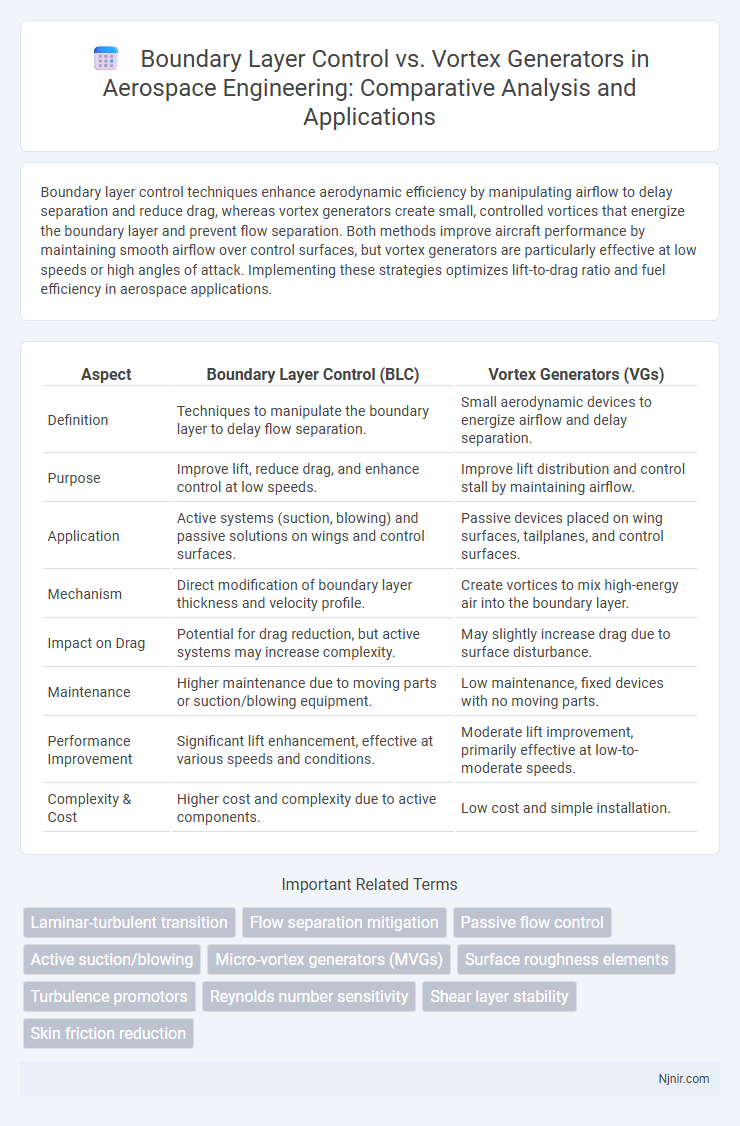

Table of Comparison

| Aspect | Boundary Layer Control (BLC) | Vortex Generators (VGs) |

|---|---|---|

| Definition | Techniques to manipulate the boundary layer to delay flow separation. | Small aerodynamic devices to energize airflow and delay separation. |

| Purpose | Improve lift, reduce drag, and enhance control at low speeds. | Improve lift distribution and control stall by maintaining airflow. |

| Application | Active systems (suction, blowing) and passive solutions on wings and control surfaces. | Passive devices placed on wing surfaces, tailplanes, and control surfaces. |

| Mechanism | Direct modification of boundary layer thickness and velocity profile. | Create vortices to mix high-energy air into the boundary layer. |

| Impact on Drag | Potential for drag reduction, but active systems may increase complexity. | May slightly increase drag due to surface disturbance. |

| Maintenance | Higher maintenance due to moving parts or suction/blowing equipment. | Low maintenance, fixed devices with no moving parts. |

| Performance Improvement | Significant lift enhancement, effective at various speeds and conditions. | Moderate lift improvement, primarily effective at low-to-moderate speeds. |

| Complexity & Cost | Higher cost and complexity due to active components. | Low cost and simple installation. |

Introduction to Boundary Layer Control in Aerospace Engineering

Boundary layer control in aerospace engineering involves manipulating the thin layer of air adjacent to aircraft surfaces to reduce drag and delay flow separation, enhancing aerodynamic efficiency. Vortex generators are small aerodynamic devices strategically placed on wings or control surfaces to create controlled vortices that energize the boundary layer, promoting smoother airflow and improved lift. Effective boundary layer control techniques, including vortex generators, contribute to fuel efficiency, increased maneuverability, and overall performance optimization in modern aircraft design.

Overview of Vortex Generators and Their Functions

Vortex generators are small aerodynamic devices installed on aircraft wings or turbine blades to enhance boundary layer control by creating controlled vortices that energize the airflow. These vortices delay flow separation, reduce drag, and improve lift by maintaining smoother airflow over the surface at higher angles of attack. Unlike traditional boundary layer control methods that may rely on suction or blowing, vortex generators provide a passive, low-maintenance solution to enhancing aerodynamic efficiency and stability.

Fundamental Principles of Boundary Layer Control

Boundary layer control involves manipulating the thin layer of fluid near a surface to reduce drag and delay flow separation, enhancing aerodynamic efficiency. Vortex generators work by creating small, controlled vortices that re-energize the boundary layer, maintaining attached flow and improving lift. Both methods rely on managing the momentum distribution within the boundary layer to optimize performance in fluid dynamics applications.

Mechanisms of Action: Passive vs Active Boundary Layer Techniques

Boundary layer control techniques can be categorized into passive and active methods, with vortex generators serving as a key example of passive devices that create small vortices to energize the boundary layer, delaying flow separation and reducing drag. Active boundary layer control involves external energy input, such as suction, blowing, or synthetic jets, to manipulate the flow more dynamically and yield greater control over boundary layer characteristics. The passive approach relies on fixed aerodynamic surfaces for continuous flow modification, whereas active techniques enable on-demand adaptability for optimizing performance under varying flight conditions.

Vortex Generators: Design, Placement, and Variations

Vortex generators are small aerodynamic devices designed to delay boundary layer separation by creating controlled vortices that energize the airflow over a surface, improving lift and reducing drag. Their placement is critical, typically near the leading edge or regions prone to flow separation, tailored to specific airfoil shapes and operating conditions for optimal effectiveness. Variations in vortex generator design include discrete vane-type, delta-winglets, and vortex generator jets, each optimized to generate vortices of differing strength and coverage to suit various aerodynamic applications.

Comparative Aerodynamic Effects: Boundary Layer Control vs Vortex Generators

Boundary layer control techniques actively manipulate airflow to delay flow separation and reduce drag, enhancing lift and improving overall aerodynamic efficiency, especially at high angles of attack. Vortex generators, by contrast, are passive devices that energize the boundary layer by creating vortices, promoting flow attachment and preventing stall with minimal added weight or complexity. While boundary layer control systems provide more precise and adjustable aerodynamic improvements, vortex generators offer a cost-effective and maintenance-friendly solution for improving aircraft performance and stability.

Impact on Aircraft Performance and Fuel Efficiency

Boundary layer control techniques enhance aircraft performance by delaying flow separation and reducing drag, resulting in improved lift-to-drag ratio and fuel efficiency. Vortex generators create controlled vortices that energize the boundary layer, delaying stall and improving control surface effectiveness without significant weight penalties. Integrating these technologies optimizes aerodynamic efficiency, leading to reduced fuel consumption and extended operational range.

Applications in Modern Aircraft: Case Studies and Examples

Boundary layer control techniques in modern aircraft, such as suction systems and blowing devices, are extensively applied to delay flow separation and improve aerodynamic efficiency, as demonstrated in the NASA F-15 ACTIVE project which utilized active suction to enhance maneuverability. Vortex generators, small aerodynamic surfaces on wings and tailplanes, promote turbulent mixing to energize the boundary layer and are widely employed in commercial jets like the Boeing 737 and Airbus A320 to maintain lift at high angles of attack and reduce stall risk. Case studies reveal that combining these methods on aircraft such as the Lockheed Martin F-22 Raptor integrates the benefits of both passive and active flow control to optimize performance in diverse flight regimes.

Maintenance, Cost, and Integration Considerations

Boundary layer control systems generally require complex maintenance due to moving parts and active components, while vortex generators offer lower maintenance with passive, fixed devices. Cost-wise, vortex generators are more budget-friendly both in initial installation and maintenance, contrasting with the higher expenses associated with boundary layer control systems. Integration of vortex generators is typically simpler and less intrusive, making them suitable for retrofitting, whereas boundary layer control systems may demand significant design alterations and space, impacting aircraft structural and system compatibility.

Future Trends in Boundary Layer Management Technologies

Future trends in boundary layer management technologies emphasize the integration of adaptive boundary layer control systems using smart materials and real-time flow sensing to optimize aerodynamic efficiency. Vortex generators are evolving with microscale designs and active control mechanisms to reduce drag and delay flow separation more effectively. Advanced computational fluid dynamics (CFD) and artificial intelligence are driving the development of hybrid boundary layer control methods combining passive and active elements to improve performance in aerospace and automotive applications.

Laminar-turbulent transition

Vortex generators effectively delay laminar-turbulent transition by energizing the boundary layer and controlling flow separation, enhancing aerodynamic performance compared to traditional passive boundary layer control techniques.

Flow separation mitigation

Vortex generators enhance boundary layer control by energizing the airflow to delay flow separation, thereby improving aerodynamic performance and reducing drag on aircraft surfaces.

Passive flow control

Passive boundary layer control using vortex generators enhances aerodynamic efficiency by delaying flow separation and reducing drag without requiring external energy input.

Active suction/blowing

Active suction/blowing in boundary layer control enhances aerodynamic performance by precisely manipulating airflow separation compared to passive vortex generators.

Micro-vortex generators (MVGs)

Micro-vortex generators (MVGs) enhance boundary layer control by creating fine-scale vortices that delay flow separation and reduce drag more effectively than conventional vortex generators.

Surface roughness elements

Surface roughness elements in boundary layer control enhance flow stability by disrupting airflow, while vortex generators use small aerodynamic surfaces to energize the boundary layer and delay flow separation.

Turbulence promotors

Vortex generators enhance boundary layer control by promoting turbulence that delays flow separation and improves aerodynamic efficiency.

Reynolds number sensitivity

Boundary layer control effectiveness varies significantly with Reynolds number, as vortex generators optimize flow separation delay primarily in moderate to high Reynolds number regimes.

Shear layer stability

Boundary layer control techniques enhance shear layer stability by delaying flow separation, whereas vortex generators energize the boundary layer to improve its resistance to adverse pressure gradients and promote dynamic shear layer stability.

Skin friction reduction

Vortex generators effectively reduce skin friction by energizing the boundary layer and delaying flow separation, thereby enhancing aerodynamic efficiency compared to traditional boundary layer control methods.

boundary layer control vs vortex generators Infographic

njnir.com

njnir.com