Single-stage-to-orbit (SSTO) vehicles aim to reach orbit without jettisoning any parts, offering potential advantages in reusability and maintenance simplicity. Multi-stage-to-orbit (MSTO) rockets shed stages during ascent, allowing for optimized mass distribution and higher payload capacity, which improves overall mission efficiency. SSTO designs face challenges in achieving the necessary mass ratio and propulsion efficiency, whereas MSTO systems benefit from proven technology but involve more complex recovery and refurbishment processes.

Table of Comparison

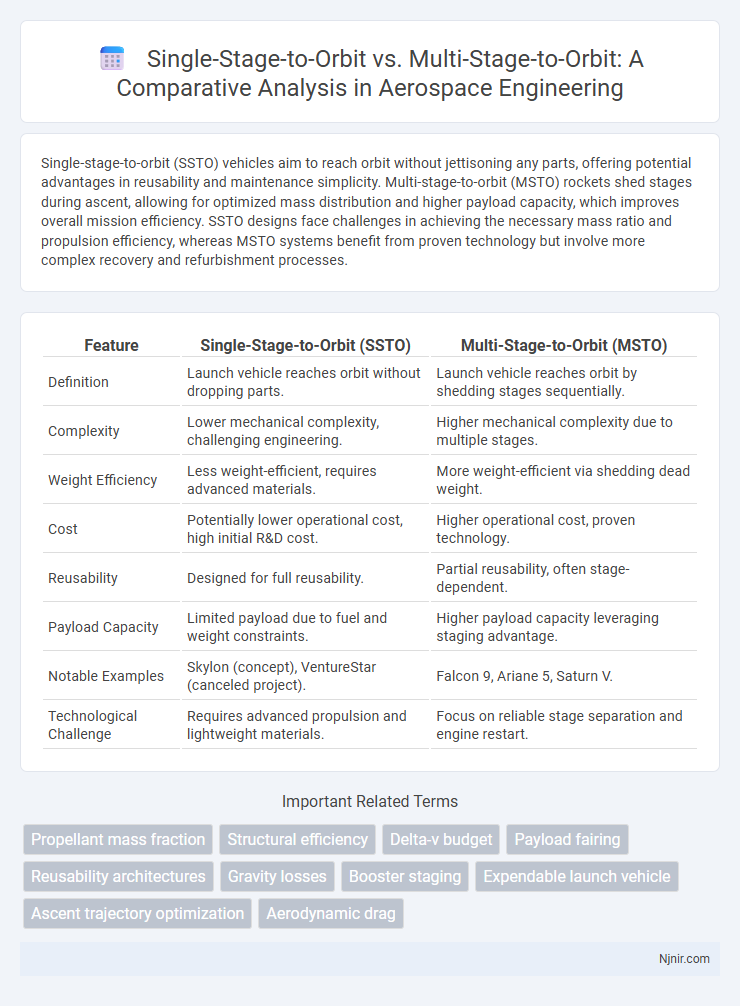

| Feature | Single-Stage-to-Orbit (SSTO) | Multi-Stage-to-Orbit (MSTO) |

|---|---|---|

| Definition | Launch vehicle reaches orbit without dropping parts. | Launch vehicle reaches orbit by shedding stages sequentially. |

| Complexity | Lower mechanical complexity, challenging engineering. | Higher mechanical complexity due to multiple stages. |

| Weight Efficiency | Less weight-efficient, requires advanced materials. | More weight-efficient via shedding dead weight. |

| Cost | Potentially lower operational cost, high initial R&D cost. | Higher operational cost, proven technology. |

| Reusability | Designed for full reusability. | Partial reusability, often stage-dependent. |

| Payload Capacity | Limited payload due to fuel and weight constraints. | Higher payload capacity leveraging staging advantage. |

| Notable Examples | Skylon (concept), VentureStar (canceled project). | Falcon 9, Ariane 5, Saturn V. |

| Technological Challenge | Requires advanced propulsion and lightweight materials. | Focus on reliable stage separation and engine restart. |

Introduction to Orbit Launch Methods

Single-stage-to-orbit (SSTO) vehicles achieve orbit using a single rocket stage, simplifying design and reducing launch costs, but require advanced propulsion systems and lightweight materials to overcome gravity losses. Multi-stage-to-orbit (MSTO) rockets discard stages sequentially, optimizing mass efficiency and achieving higher payload capacity despite increased system complexity. Both methods are fundamental in space launch technology, with SSTO promising reusability and MSTO offering proven reliability for heavy payloads.

Defining Single-Stage-to-Orbit (SSTO)

Single-Stage-to-Orbit (SSTO) vehicles achieve orbit without shedding parts, relying on a single rocket body to reach orbital velocity and altitude. SSTO designs reduce complexity and turnaround time by eliminating the need for stage separation, but require advanced lightweight materials and highly efficient propulsion systems, such as aerospike engines or advanced cryogenic fuels. Compared to Multi-Stage-to-Orbit (MSTO) rockets, SSTO faces significant engineering challenges in balancing structural mass, fuel capacity, and thrust-to-weight ratio to overcome Earth's gravity in one continuous ascent.

Understanding Multi-Stage-to-Orbit (MSTO)

Multi-Stage-to-Orbit (MSTO) rockets achieve orbital velocity by discarding stages sequentially, reducing mass and improving efficiency during ascent. Each stage contains its own engines and fuel tanks optimized for specific altitude ranges, enabling higher payload capacity compared to single-stage vehicles. MSTO designs are favored for heavy-lift launches due to their improved thrust-to-weight ratio and established reliability in overcoming Earth's gravity.

Historical Developments and Milestones

Single-stage-to-orbit (SSTO) concepts date back to early space exploration research, with significant milestones including the X-15 rocket plane tests in the 1960s and later the DC-X program in the 1990s aimed at reusable SSTO technology. Multi-stage-to-orbit (MSTO) has dominated spaceflight since the 1950s, with landmark achievements such as the Saturn V rocket enabling the Apollo moon missions and the Space Shuttle program, which utilized multiple stages including solid boosters and an orbiter. Technological advances and evolving mission requirements have continuously shaped the development trajectories of both SSTO and MSTO systems, highlighting distinct engineering challenges and operational trade-offs.

Propulsion Systems and Design Complexity

Single-stage-to-orbit (SSTO) vehicles utilize a single integrated propulsion system designed for the entire ascent, demanding highly efficient rocket engines with optimized thrust-to-weight ratios and advanced fuel mixtures to maximize payload capacity. Multi-stage-to-orbit (MSTO) rockets employ multiple propulsion systems arranged in stages that are sequentially jettisoned, reducing weight during flight but increasing overall design complexity due to the need for reliable stage separation mechanisms and varied engine configurations. SSTO design simplifies structural elements by avoiding interstage components, whereas MSTO systems require intricate staging hardware and coordination of propulsion transitions to ensure mission success.

Payload Capacity and Performance Efficiency

Single-stage-to-orbit (SSTO) vehicles typically have lower payload capacity due to the need to carry all propellant and structural mass from launch to orbit without discarding stages. Multi-stage-to-orbit (MSTO) rockets enhance performance efficiency by shedding empty fuel tanks and engines during ascent, significantly increasing payload mass to orbit. MSTO designs achieve higher payload fractions, often exceeding 3-5% of initial launch mass, whereas SSTO vehicles rarely surpass 1-2%, limiting their operational payload capability.

Reusability and Cost Effectiveness

Single-stage-to-orbit (SSTO) vehicles offer potential reusability benefits by minimizing the number of components requiring refurbishment, reducing turnaround time and operational complexity. Multi-stage-to-orbit (MSTO) systems, while traditionally less reusable due to discarded stages, have increasingly incorporated reusable boosters and engines to improve cost efficiency. SSTO designs typically face higher engineering challenges and material costs, but streamlined maintenance can lower overall expenses compared to MSTO architectures with complex staging and recovery processes.

Technical Challenges and Engineering Solutions

Single-stage-to-orbit (SSTO) faces significant technical challenges such as achieving extremely high mass fractions and efficient propulsion systems to reach orbital velocity without dropping stages. Engineering solutions for SSTO often involve advanced materials to reduce weight, high-performance engines with reusable designs, and innovative thermal protection systems to manage re-entry heat. Multi-stage-to-orbit (MSTO) addresses these challenges by discarding spent stages, allowing each stage to be optimized for different flight phases, which simplifies propulsion demands and improves overall mass efficiency despite increased complexity in vehicle design and staging mechanisms.

Environmental Impact Comparison

Single-stage-to-orbit (SSTO) vehicles typically generate less space debris and reduce material waste since they do not discard stages during ascent, lowering environmental contamination risks in orbit and on Earth. Multi-stage-to-orbit (MSTO) rockets, however, often release multiple spent boosters and fuel tanks, contributing to increased ocean and land pollution alongside higher atmospheric emissions from repeated engine firings during stage separations. Lifecycle assessments reveal SSTO systems may offer reduced carbon footprints and fewer toxic propellant residues, whereas MSTO benefits from optimized fuel efficiency per stage at the expense of greater environmental disturbance due to discarded hardware.

Future Outlook and Industry Trends

Single-stage-to-orbit (SSTO) technology promises simplified launch processes with reusable vehicles aiming to reduce costs and turnaround times, attracting significant interest from aerospace startups and national space agencies focused on rapid deployment and sustainable space access. Multi-stage-to-orbit (MSTO) systems continue to dominate due to their proven reliability and efficiency in payload delivery, with ongoing advancements in lightweight materials and reusable components enhancing performance and lowering expenses. Industry trends indicate a competitive coexistence where SSTO development advances through breakthroughs in propulsion and thermal protection, while MSTO benefits from incremental optimization, reflecting a diversified approach to next-generation space launch solutions.

Propellant mass fraction

Single-stage-to-orbit vehicles require significantly higher propellant mass fractions, often exceeding 80%, compared to multi-stage-to-orbit vehicles, which optimize mass efficiency by shedding stages and typically operate with lower overall propellant mass fractions.

Structural efficiency

Single-stage-to-orbit vehicles typically suffer from lower structural efficiency due to the need to carry full fuel loads and heavier heat shielding, whereas multi-stage-to-orbit designs optimize structural efficiency by shedding mass at each stage, enabling higher payload fractions.

Delta-v budget

Single-stage-to-orbit vehicles require significantly higher delta-v budgets, typically over 9.3 km/s including gravity and atmospheric losses, compared to multi-stage-to-orbit rockets that achieve orbital velocity more efficiently by discarding stages and thus reducing the total delta-v needed for orbit insertion.

Payload fairing

Single-stage-to-orbit vehicles require larger, more complex payload fairings due to their need to maintain structural integrity and thermal protection throughout ascent, while multi-stage-to-orbit rockets can employ smaller, optimized fairings tailored to individual stages, enhancing payload capacity and aerodynamic efficiency.

Reusability architectures

Single-stage-to-orbit (SSTO) vehicles prioritize full reusability with simpler architectures but face challenges in mass fraction and performance, while multi-stage-to-orbit (MSTO) designs achieve higher payload capacity and efficiency by discarding stages, with partial reusability increasingly enabled through advancements in booster recovery and refurbishment technologies.

Gravity losses

Single-stage-to-orbit rockets experience significantly higher gravity losses compared to multi-stage-to-orbit vehicles due to prolonged engine burn times required to reach orbital velocity without shedding mass.

Booster staging

Single-stage-to-orbit vehicles eliminate booster staging complexity but face higher mass fraction challenges, while multi-stage-to-orbit rockets utilize booster staging to shed weight and improve overall payload efficiency.

Expendable launch vehicle

Single-stage-to-orbit expendable launch vehicles offer simpler design and quicker launch turnaround compared to multi-stage expendable launch vehicles, which provide higher payload capacity and greater efficiency by shedding stages during ascent.

Ascent trajectory optimization

Single-stage-to-orbit vehicles face greater ascent trajectory optimization challenges due to higher mass fractions and limited staging flexibility compared to multi-stage-to-orbit systems, which leverage sequential staging to achieve optimized velocity increments and fuel efficiency.

Aerodynamic drag

Single-stage-to-orbit vehicles experience higher aerodynamic drag due to their larger mass and surface area throughout flight, whereas multi-stage-to-orbit rockets reduce drag by shedding stages and thus decreasing weight and cross-sectional area during ascent.

Single-stage-to-orbit vs Multi-stage-to-orbit Infographic

njnir.com

njnir.com