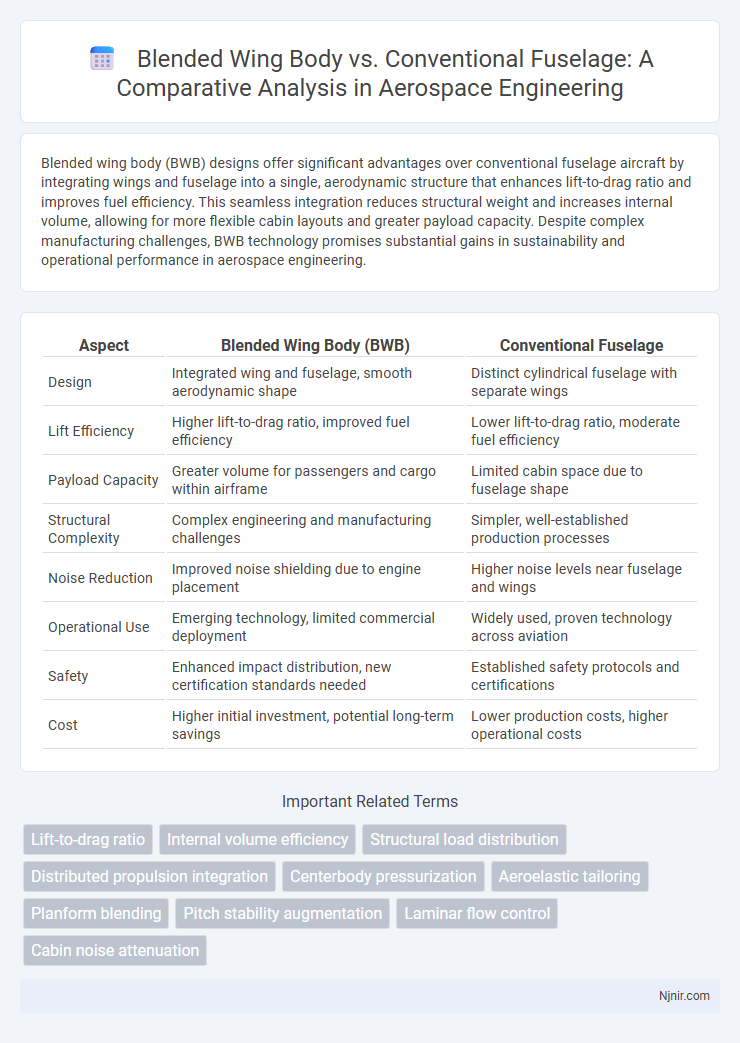

Blended wing body (BWB) designs offer significant advantages over conventional fuselage aircraft by integrating wings and fuselage into a single, aerodynamic structure that enhances lift-to-drag ratio and improves fuel efficiency. This seamless integration reduces structural weight and increases internal volume, allowing for more flexible cabin layouts and greater payload capacity. Despite complex manufacturing challenges, BWB technology promises substantial gains in sustainability and operational performance in aerospace engineering.

Table of Comparison

| Aspect | Blended Wing Body (BWB) | Conventional Fuselage |

|---|---|---|

| Design | Integrated wing and fuselage, smooth aerodynamic shape | Distinct cylindrical fuselage with separate wings |

| Lift Efficiency | Higher lift-to-drag ratio, improved fuel efficiency | Lower lift-to-drag ratio, moderate fuel efficiency |

| Payload Capacity | Greater volume for passengers and cargo within airframe | Limited cabin space due to fuselage shape |

| Structural Complexity | Complex engineering and manufacturing challenges | Simpler, well-established production processes |

| Noise Reduction | Improved noise shielding due to engine placement | Higher noise levels near fuselage and wings |

| Operational Use | Emerging technology, limited commercial deployment | Widely used, proven technology across aviation |

| Safety | Enhanced impact distribution, new certification standards needed | Established safety protocols and certifications |

| Cost | Higher initial investment, potential long-term savings | Lower production costs, higher operational costs |

Introduction to Aircraft Fuselage Designs

Blended wing body (BWB) aircraft fuse the wing and fuselage into a seamless aerodynamic shape, enhancing lift and fuel efficiency compared to conventional fuselage designs, which feature a distinct cylindrical body for passenger and cargo space. The BWB design reduces drag and structural weight by distributing loads more evenly, improving overall aircraft performance and environmental impact. Conventional fuselages remain prevalent due to established manufacturing processes and interior layout flexibility, while BWBs are gaining interest in next-generation aerospace development for their innovative aerodynamic advantages.

Overview of Conventional Tube-and-Wing Configurations

Conventional tube-and-wing aircraft feature a cylindrical fuselage with distinct wings attached to the sides, providing proven structural simplicity and ease of manufacturing. This design efficiently accommodates passengers and cargo within the fuselage while allowing straightforward integration of engines and landing gear. Although less aerodynamically efficient than blended wing body designs, tube-and-wing configurations offer reliable performance and well-established maintenance practices.

Fundamentals of Blended Wing Body (BWB) Architecture

Blended Wing Body (BWB) architecture integrates the wing and fuselage into a single seamless structure, enhancing aerodynamic efficiency by reducing drag and improving lift-to-drag ratio compared to conventional fuselage designs. This design distributes structural loads more evenly and increases internal volume, allowing for lighter airframes and improved fuel efficiency. BWB fundamentally relies on advanced materials and computational fluid dynamics to optimize airflow and structural integrity within its unconventional, wide, and flat body shape.

Aerodynamic Efficiency Comparison

Blended wing body (BWB) designs exhibit significantly lower drag coefficients compared to conventional fuselage aircraft, resulting in enhanced lift-to-drag ratios and improved fuel efficiency. The seamless integration of wings and fuselage in BWB reduces interference drag and promotes smoother airflow, which minimizes turbulent wake formation. Computational fluid dynamics studies reveal that BWBs can achieve up to 20-30% better aerodynamic efficiency, making them advantageous for long-range and heavy payload missions.

Structural Strength and Weight Analysis

Blended wing body (BWB) designs exhibit superior structural strength through load distribution across the entire airframe, reducing stress concentrations typical in conventional fuselage structures. The integration of wing and body allows for a lighter overall weight by eliminating redundant support elements found in traditional cylindrical fuselages. Weight analysis reveals that BWBs achieve enhanced fuel efficiency due to their optimized aerodynamics and reduced structural mass, contributing to improved payload capacity and lower operational costs.

Fuel Consumption and Environmental Impact

Blended wing body (BWB) designs reduce fuel consumption by improving aerodynamic efficiency, resulting in lower drag and enhanced lift-to-drag ratios compared to conventional fuselage aircraft. This increased efficiency translates to significant reductions in carbon dioxide emissions, contributing to a smaller environmental footprint. Research indicates that BWBs can achieve fuel savings of up to 20-30%, making them a promising solution for sustainable aviation development.

Flight Stability and Control Challenges

Blended wing body (BWB) designs present complex flight stability and control challenges compared to conventional fuselage aircraft due to their unique aerodynamic properties and distributed control surfaces. The absence of a distinct tail section in BWB aircraft complicates pitch and yaw stability, requiring advanced fly-by-wire systems and adaptive control algorithms to maintain balanced flight. Conventional fuselage aircraft benefit from well-established stability characteristics and control surface configurations that provide predictable responses, whereas BWB designs demand innovative control strategies to address their inherently nonlinear and coupled flight dynamics.

Payload and Cabin Design Differences

Blended wing body (BWB) aircraft integrate the payload within a wide, continuous wing structure, maximizing internal volume for enhanced payload capacity and flexible cabin layouts, unlike conventional fuselage designs with a tubular body limiting space. BWB cabins enable spacious, open interiors amenable to multiple configurations, improving passenger comfort and cargo versatility. Conventional fuselage aircraft maintain traditional linear cabin designs that constrain seating arrangements and cargo placement due to narrower cross-sections and structural frames.

Manufacturing and Maintenance Considerations

Blended wing body (BWB) aircraft present manufacturing challenges due to their integrated structure, requiring advanced composite materials and precise fabrication techniques, unlike conventional fuselage designs which benefit from standardized, modular assembly lines. Maintenance for BWB is often more complex, as the seamless aerodynamic shape limits access to internal systems and demands specialized inspection tools, whereas conventional fuselage aircraft have easily accessible compartments and established maintenance protocols. Cost implications arise from these factors, with BWBs potentially offering fuel efficiency gains but higher initial manufacturing and upkeep expenses compared to traditional fuselage configurations.

Future Prospects and Industry Adoption

Blended wing body (BWB) aircraft offer significant fuel efficiency improvements and reduced carbon emissions compared to conventional fuselage designs, positioning them as a key innovation for sustainable aviation. Major aerospace companies and research institutions are increasingly investing in BWB technology, driven by regulatory pressure and rising fuel costs, signaling stronger industry adoption in the coming decades. Advances in materials science and aerodynamic modeling are expected to address current manufacturing and certification challenges, accelerating the integration of BWB configurations into commercial fleets by 2040.

Lift-to-drag ratio

The blended wing body design achieves a significantly higher lift-to-drag ratio than conventional fuselage aircraft, enhancing aerodynamic efficiency and fuel economy.

Internal volume efficiency

Blended wing body designs achieve up to 30% greater internal volume efficiency compared to conventional fuselage aircraft by integrating the wing and body into a unified, aerodynamically optimized structure.

Structural load distribution

Blended wing body designs optimize structural load distribution by integrating wings and fuselage into a unified airframe, reducing stress concentrations and enhancing load transfer efficiency compared to traditional fuselage-centric aircraft architectures.

Distributed propulsion integration

Blended wing body designs offer superior distributed propulsion integration by enabling seamless embedding of multiple engines across the airframe, enhancing aerodynamic efficiency and reducing fuel consumption compared to conventional fuselage configurations.

Centerbody pressurization

Blended wing body designs enable more efficient centerbody pressurization by distributing pressure loads across a wider internal volume compared to the concentrated fuselage pressurization in conventional aircraft.

Aeroelastic tailoring

Blended wing body aircraft exhibit superior aeroelastic tailoring capabilities compared to conventional fuselage designs, enabling enhanced structural efficiency and aerodynamic performance through optimized load distribution and material anisotropy control.

Planform blending

Blended wing body designs integrate the wing and fuselage into a seamless planform, enhancing aerodynamic efficiency and reducing drag compared to conventional fuselage aircraft with distinct, separate sections.

Pitch stability augmentation

Blended wing body aircraft demonstrate enhanced pitch stability augmentation compared to conventional fuselage designs due to their integrated aerodynamic surfaces and distributed lift characteristics.

Laminar flow control

Blended wing body designs enable more effective laminar flow control than conventional fuselages by reducing surface curvature and minimizing flow disruptions, resulting in lower drag and improved aerodynamic efficiency.

Cabin noise attenuation

Blended wing body aircraft significantly reduce cabin noise attenuation compared to conventional fuselage designs due to their integrated aerodynamic structure that minimizes engine noise transmission and airflow disturbances.

Blended wing body vs Conventional fuselage Infographic

njnir.com

njnir.com