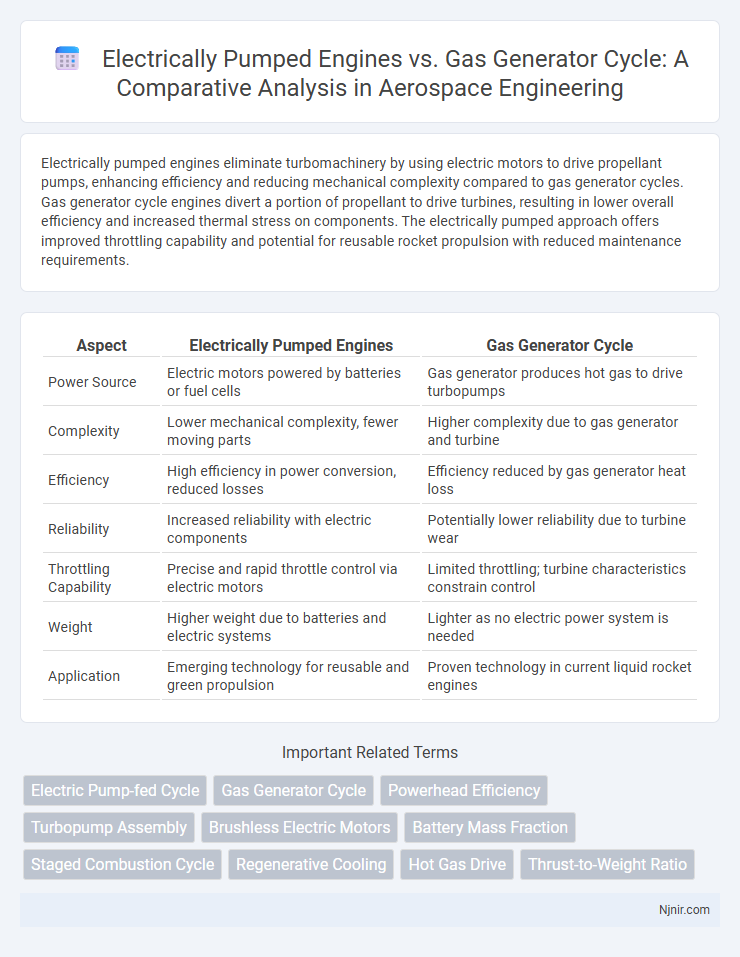

Electrically pumped engines eliminate turbomachinery by using electric motors to drive propellant pumps, enhancing efficiency and reducing mechanical complexity compared to gas generator cycles. Gas generator cycle engines divert a portion of propellant to drive turbines, resulting in lower overall efficiency and increased thermal stress on components. The electrically pumped approach offers improved throttling capability and potential for reusable rocket propulsion with reduced maintenance requirements.

Table of Comparison

| Aspect | Electrically Pumped Engines | Gas Generator Cycle |

|---|---|---|

| Power Source | Electric motors powered by batteries or fuel cells | Gas generator produces hot gas to drive turbopumps |

| Complexity | Lower mechanical complexity, fewer moving parts | Higher complexity due to gas generator and turbine |

| Efficiency | High efficiency in power conversion, reduced losses | Efficiency reduced by gas generator heat loss |

| Reliability | Increased reliability with electric components | Potentially lower reliability due to turbine wear |

| Throttling Capability | Precise and rapid throttle control via electric motors | Limited throttling; turbine characteristics constrain control |

| Weight | Higher weight due to batteries and electric systems | Lighter as no electric power system is needed |

| Application | Emerging technology for reusable and green propulsion | Proven technology in current liquid rocket engines |

Introduction to Rocket Propulsion Cycles

Electric pump-fed rocket engines utilize electric motors to drive propellant pumps, allowing precise control of flow rates and simplifying engine design by eliminating complex turbomachinery. Gas generator cycle engines operate by burning a portion of propellants in a gas generator to drive turbines connected to pumps, providing high thrust but involving higher thermal and mechanical stresses. Both cycles represent fundamental propulsion methods with distinct trade-offs in efficiency, complexity, and operational flexibility within modern rocket engine design.

Fundamentals of Electrically Pumped Engines

Electrically pumped engines use electric motors to drive propellant pumps, eliminating the need for gas generators and their associated turbine machinery, which simplifies engine design and improves efficiency. These engines allow precise control of propellant flow rates, enhancing throttle response and reducing mechanical complexity compared to the gas generator cycle, where combustion gas drives turbines to power pumps. The fundamental advantage lies in the decoupling of pumping mechanisms from combustion, enabling higher performance flexibility and potential reuse in rocket propulsion systems.

Overview of Gas Generator Cycle Engines

Gas generator cycle engines use a separate combustion chamber called the gas generator to produce hot gases that drive the turbine powering the fuel and oxidizer pumps. This cycle allows for efficient turbopump operation while the main combustion chamber operates at higher pressures and temperatures, improving overall engine performance. Commonly employed in rocket engines like the Rocketdyne F-1 and SpaceX Merlin, gas generator cycles balance complexity, reliability, and thrust output for various launch applications.

Key Components Comparison

Electrically pumped engines use electric motors powered by batteries to drive the propellant pumps, eliminating the need for a separate gas generator. In contrast, gas generator cycle engines rely on a dedicated gas generator that burns propellant to produce high-pressure gas for turbine operation. Key components in electrically pumped systems include electric motors, batteries, and power electronics, while gas generator cycles feature combustion chambers, turbines, and gas generators.

Efficiency and Performance Analysis

Electrically pumped engines eliminate the need for complex turbomachinery by using electric motors to drive propellant pumps, resulting in improved efficiency through precise flow control and reduced mechanical losses compared to traditional gas generator cycles. Gas generator cycle engines burn a portion of propellant in a gas generator to drive turbines, inherently sacrificing some propellant energy and lowering overall efficiency but offering a proven performance baseline with higher thrust density. Performance analysis shows that electrically pumped engines achieve higher specific impulse and improved throttleability, while gas generator cycles provide robust combustion stability and simpler thermal management, making each suitable for different mission profiles depending on efficiency and operational requirements.

Reliability and Complexity Factors

Electrically pumped engines offer improved reliability by eliminating turbomachinery associated with gas generator cycles, reducing the risk of mechanical failure and simplifying engine operation. Gas generator cycle engines involve complex plumbing and turbopump systems that increase maintenance demands and potential failure points. The simplified architecture of electrically pumped designs enhances operational lifespan and reduces the likelihood of malfunctions in launch or mission-critical scenarios.

Propellant Utilization and Efficiency

Electrically pumped engines achieve higher propellant utilization by precisely controlling turbopump speeds through electric motors, resulting in optimized flow rates and reduced propellant waste. Gas generator cycles, while simpler, experience lower efficiency due to the diversion of propellant to drive turbines, which does not contribute directly to thrust. Consequently, electrically pumped systems offer superior overall efficiency by maximizing propellant conversion into kinetic energy, enhancing specific impulse compared to traditional gas generator engines.

Scalability and Application Suitability

Electrically pumped engines offer superior scalability due to their modular design and precise control over pump speed, making them ideal for small to medium-sized launch vehicles and lunar landers. Gas generator cycle engines excel in high-thrust applications and heavy-lift launch vehicles because of their proven reliability and simpler turbopump drive system. The choice between these technologies depends on mission requirements, with electrically pumped engines favored for flexibility and efficiency in variable thrust scenarios, while gas generator cycles dominate in high-thrust, high-reliability contexts.

Environmental Impact and Sustainability

Electrically pumped engines offer enhanced environmental benefits by eliminating the need for gas generators, reducing toxic emissions and improving overall sustainability. These engines enable more efficient fuel consumption and lower carbon footprints due to their simplified design and precise electric motor control. Gas generator cycle engines generate additional pollutants through combustion in the gas generator, leading to higher greenhouse gas emissions and greater environmental concerns.

Future Trends in Rocket Engine Technology

Electrically pumped engines enhance efficiency and reduce complexity by replacing traditional turbopumps with electric motors powered by advanced battery or fuel cell systems, enabling precise thrust control and reliability improvements. Future trends emphasize integrating high-energy-density batteries and lightweight power electronics to further optimize specific impulse and engine restart capabilities while reducing overall vehicle mass. Advancements in additive manufacturing and thermal management are expected to accelerate the adoption of electric pump-fed architectures over conventional gas generator cycles in next-generation launch vehicles.

Electric Pump-fed Cycle

Electric pump-fed cycles enhance rocket engine efficiency by using electric motors to drive propellant pumps, eliminating complex gas generator components and boosting overall system reliability.

Gas Generator Cycle

Gas generator cycle engines utilize a separate combustion process to drive turbines that power fuel pumps, enhancing performance and reliability compared to electrically pumped systems.

Powerhead Efficiency

Electrically pumped engines achieve higher powerhead efficiency than gas generator cycle engines by eliminating turbine-driven pumps and reducing energy losses.

Turbopump Assembly

Electrically pumped engines utilize electric motors to drive turbopumps, eliminating the complexity and high temperatures of gas generator cycles, which rely on combustion gases to power turbopump assemblies.

Brushless Electric Motors

Brushless electric motors in electrically pumped engines offer higher efficiency and reduced mechanical complexity compared to gas generator cycle systems, enabling precise control and improved reliability in rocket propulsion.

Battery Mass Fraction

Electrically pumped engines typically achieve lower battery mass fractions compared to gas generator cycle engines due to their reliance on high-energy-density batteries instead of heavy turbopumps and gas generator systems.

Staged Combustion Cycle

Electrically pumped engines optimize performance by eliminating turbopumps and complex gas generator cycles, while staged combustion cycle engines enhance efficiency and thrust through high-pressure combustion and full propellant utilization.

Regenerative Cooling

Electrically pumped engines enable efficient regenerative cooling by using electric motors to drive propellant pumps, reducing system complexity and enhancing thermal management compared to traditional gas generator cycle engines.

Hot Gas Drive

Hot gas drive systems in gas generator cycle engines use combustion gases to power turbines directly, whereas electrically pumped engines eliminate hot gas turbines by relying on electric motors powered by batteries or generators for propellant pumping.

Thrust-to-Weight Ratio

Electrically pumped engines achieve higher thrust-to-weight ratios by eliminating heavy turbomachinery and gas generators found in gas generator cycle engines, optimizing overall propulsion efficiency.

Electrically Pumped Engines vs Gas Generator Cycle Infographic

njnir.com

njnir.com