Cryogenic propellants, such as liquid hydrogen and liquid oxygen, offer higher specific impulse and performance but require complex insulation and handling due to their extremely low temperatures. Storable propellants, like hydrazine and nitrogen tetroxide, remain liquid at ambient conditions, enabling simpler storage and longer mission durations, though they typically have lower efficiency and higher toxicity. The choice between cryogenic and storable propellants depends on mission requirements, including engine performance, storage constraints, and safety considerations.

Table of Comparison

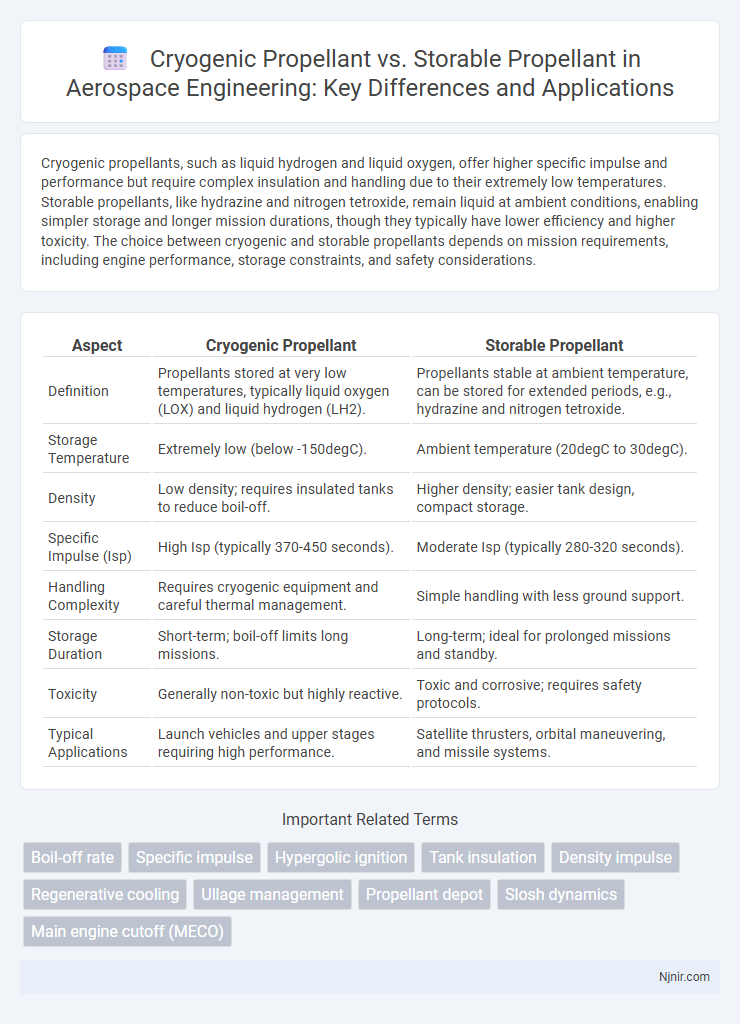

| Aspect | Cryogenic Propellant | Storable Propellant |

|---|---|---|

| Definition | Propellants stored at very low temperatures, typically liquid oxygen (LOX) and liquid hydrogen (LH2). | Propellants stable at ambient temperature, can be stored for extended periods, e.g., hydrazine and nitrogen tetroxide. |

| Storage Temperature | Extremely low (below -150degC). | Ambient temperature (20degC to 30degC). |

| Density | Low density; requires insulated tanks to reduce boil-off. | Higher density; easier tank design, compact storage. |

| Specific Impulse (Isp) | High Isp (typically 370-450 seconds). | Moderate Isp (typically 280-320 seconds). |

| Handling Complexity | Requires cryogenic equipment and careful thermal management. | Simple handling with less ground support. |

| Storage Duration | Short-term; boil-off limits long missions. | Long-term; ideal for prolonged missions and standby. |

| Toxicity | Generally non-toxic but highly reactive. | Toxic and corrosive; requires safety protocols. |

| Typical Applications | Launch vehicles and upper stages requiring high performance. | Satellite thrusters, orbital maneuvering, and missile systems. |

Introduction to Propellant Types in Aerospace Engineering

Cryogenic propellants, such as liquid hydrogen and liquid oxygen, offer high specific impulse and energy density, making them ideal for upper-stage rockets and deep-space missions. Storable propellants, including hydrazine and nitrogen tetroxide, remain stable at ambient temperatures, providing reliable performance for long-duration missions and spacecraft requiring multiple engine restarts. Understanding the trade-offs between cryogenic and storable propellants is essential in aerospace engineering for optimizing rocket propulsion systems based on mission requirements.

Defining Cryogenic Propellants

Cryogenic propellants are liquefied gases stored at extremely low temperatures, typically below -150degC, enabling high density and energy efficiency for rocket propulsion. Common cryogenic propellants include liquid hydrogen (LH2) and liquid oxygen (LOX), which offer superior specific impulse compared to storable propellants like hydrazine and nitrogen tetroxide. These propellants require sophisticated insulation and handling systems to maintain their ultra-cold state and prevent boil-off during storage and flight.

Understanding Storable Propellants

Storable propellants, composed mainly of hydrazine and nitrogen tetroxide, offer significant advantages in spacecraft design due to their ability to remain stable and usable at room temperature for extended periods, unlike cryogenic propellants which require ultra-low temperatures for storage. These hypergolic fuels ignite spontaneously on contact, enabling simpler and more reliable engine ignition systems critical for mission flexibility and long-duration space missions. Their density and storability reduce the complexity of thermal management systems, making storable propellants ideal for satellites, upper stages, and deep space probes.

Key Physical and Chemical Properties

Cryogenic propellants such as liquid oxygen and liquid hydrogen possess extremely low boiling points, requiring insulated storage tanks to maintain their cryogenic state and prevent rapid boil-off, with densities generally lower than storable propellants. Storable propellants like hydrazine and nitrogen tetroxide remain liquid at ambient temperatures, exhibiting higher vapor pressures and greater chemical stability but tend to be hypergolic and highly toxic. The choice impacts propulsion system complexity, where cryogenics offer higher specific impulse while storables allow simpler engine design and long-term storage without refrigeration.

Storage and Handling Requirements

Cryogenic propellants, such as liquid hydrogen and liquid oxygen, require storage at extremely low temperatures below -150degC to maintain their liquid state, demanding highly insulated tanks and specialized handling equipment to prevent boil-off and ensure safety. Storable propellants, typically hypergolic fuels like hydrazine or nitrogen tetroxide, remain liquid at ambient temperatures, enabling simpler storage and handling without the need for cryogenic refrigeration systems. The trade-off involves increased complexity and cost for cryogenic systems but offers higher performance and specific impulse compared to storable propellants that provide operational readiness and ease of use.

Performance Metrics: Specific Impulse and Efficiency

Cryogenic propellants, such as liquid hydrogen and liquid oxygen, deliver higher specific impulse values typically around 450 seconds, translating to superior efficiency and greater thrust-to-weight ratios for launch vehicles. Storable propellants, like hydrazine and nitrogen tetroxide, offer lower specific impulse, usually between 280 to 320 seconds, but provide advantages in long-term storage stability and operational readiness. The choice between these propellant types hinges on mission requirements balancing specific impulse and efficiency against handling complexity and storage constraints.

Applications in Launch Vehicles and Spacecraft

Cryogenic propellants, such as liquid hydrogen and liquid oxygen, are primarily used in launch vehicles requiring high specific impulse and performance, enabling heavy payload capacities and deep-space missions like the Space Shuttle and Ariane 5. Storable propellants, including hydrazine and nitrogen tetroxide, are favored for spacecraft propulsion due to their stability at ambient temperatures, facilitating long-term missions, satellite station-keeping, and orbital maneuvering without the need for complex cooling systems. The choice between cryogenic and storable propellants directly impacts mission duration, vehicle design, and operational complexity in both launch and in-space propulsion systems.

Safety Considerations and Risks

Cryogenic propellants, such as liquid oxygen and liquid hydrogen, pose significant safety risks due to their extremely low temperatures, which can cause material brittleness and frostbite hazards, requiring specialized insulated storage and handling systems. Storable propellants, including hydrazine-based fuels, are chemically toxic and highly corrosive, presenting acute health risks through inhalation or skin contact and necessitating strict handling protocols and protective equipment. Both propellant types require rigorous safety measures to mitigate risks of leaks, fires, or explosions, but cryogenic fuels demand more complex thermal management while storables require enhanced chemical hazard controls.

Cost Implications and Logistics

Cryogenic propellants such as liquid hydrogen and liquid oxygen require complex insulated storage and handling systems, significantly increasing launch infrastructure and vehicle costs. Storable propellants like hydrazine and nitrogen tetroxide, while toxic and lower-performing, offer simpler logistics with ambient temperature storage enabling longer-duration missions without extensive cryogenic support. The trade-off between high initial investment for cryogenics versus ongoing operational costs and handling risks for storables largely drives mission design and budget allocation.

Future Trends and Advancements in Propellant Technologies

Emerging trends in cryogenic propellant technology emphasize enhanced thermal insulation and zero-boil-off storage to improve long-duration space missions, leveraging advanced materials and active cooling systems. Storable propellants are evolving with non-toxic, high-density formulations, aimed at reducing handling hazards and increasing mission safety in reusable launch vehicles. Innovations in hybrid propulsion systems integrating cryogenic and storable propellants promise optimized performance and flexibility for diverse mission profiles in deep space exploration.

Boil-off rate

Cryogenic propellants exhibit higher boil-off rates due to their extremely low storage temperatures compared to storable propellants, which remain stable and experience minimal boil-off at ambient conditions.

Specific impulse

Cryogenic propellants typically offer higher specific impulse values, often exceeding 450 seconds in vacuum, compared to storable propellants which generally deliver specific impulses around 280-320 seconds.

Hypergolic ignition

Hypergolic propellants ignite spontaneously upon contact, providing reliable engine starts unlike cryogenic propellants, which require precise ignition systems due to their extremely low temperatures.

Tank insulation

Cryogenic propellant tanks require advanced multilayer insulation and active cooling systems to maintain ultra-low temperatures, whereas storable propellant tanks use simpler thermal insulation due to their ambient temperature stability.

Density impulse

Cryogenic propellants offer higher specific impulse but lower density impulse compared to storable propellants, which have higher density and thereby provide greater thrust per unit volume.

Regenerative cooling

Regenerative cooling in cryogenic propellant engines efficiently manages extremely low temperatures using the fuel as a coolant, whereas storable propellant engines often rely on less effective thermal protection due to higher operating temperatures and chemical stability.

Ullage management

Efficient ullage management in cryogenic propellant systems involves pressurization to prevent fluid sloshing and maintain tank stability, whereas storable propellants require less ullage control due to their higher density and ambient storage capability.

Propellant depot

Cryogenic propellant depots offer high specific impulse and mass efficiency for deep-space missions but require advanced insulation and boil-off management, whereas storable propellant depots provide simpler storage and handling with lower performance, making depot selection critical for mission duration and refueling strategies.

Slosh dynamics

Cryogenic propellants exhibit more complex and higher-amplitude slosh dynamics compared to storable propellants due to their lower viscosity and temperature sensitivity, necessitating advanced damping systems in spacecraft tank designs.

Main engine cutoff (MECO)

Main Engine Cutoff (MECO) timing in cryogenic propellant systems is precisely controlled due to their higher specific impulse and boil-off sensitivity, whereas storable propellant systems allow more flexible MECO timing but with lower performance efficiency.

cryogenic propellant vs storable propellant Infographic

njnir.com

njnir.com