Composite materials in aerospace engineering offer superior strength-to-weight ratios compared to aluminum alloys, leading to significant fuel efficiency and performance improvements. Their resistance to corrosion and fatigue enhances structural durability, reducing maintenance costs over the aircraft's lifespan. However, aluminum alloys remain favored for their cost-effectiveness and proven reliability in a wide range of aerospace applications.

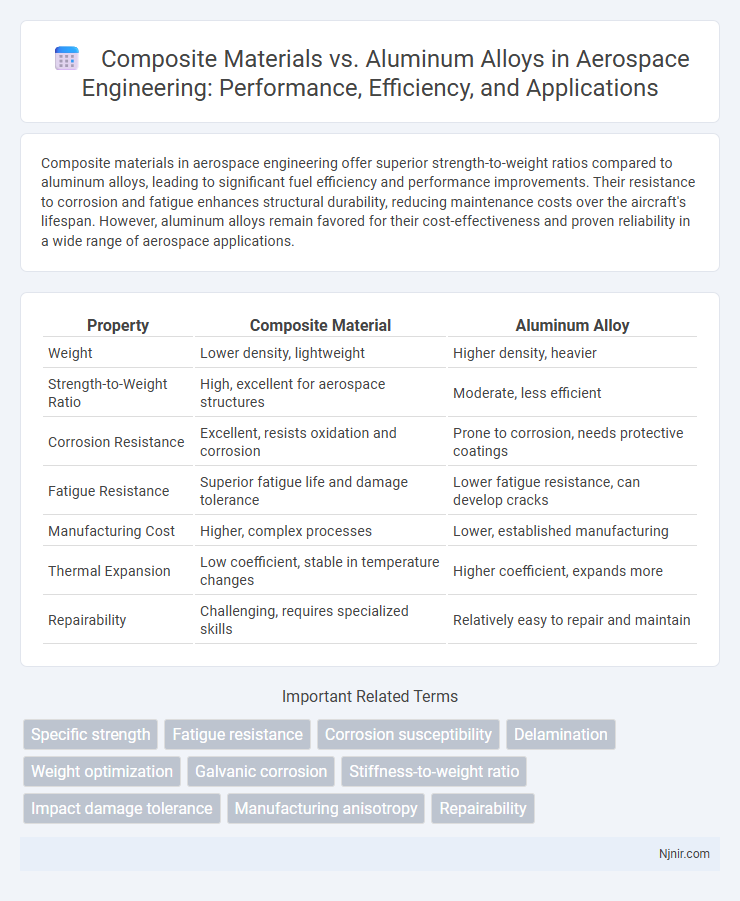

Table of Comparison

| Property | Composite Material | Aluminum Alloy |

|---|---|---|

| Weight | Lower density, lightweight | Higher density, heavier |

| Strength-to-Weight Ratio | High, excellent for aerospace structures | Moderate, less efficient |

| Corrosion Resistance | Excellent, resists oxidation and corrosion | Prone to corrosion, needs protective coatings |

| Fatigue Resistance | Superior fatigue life and damage tolerance | Lower fatigue resistance, can develop cracks |

| Manufacturing Cost | Higher, complex processes | Lower, established manufacturing |

| Thermal Expansion | Low coefficient, stable in temperature changes | Higher coefficient, expands more |

| Repairability | Challenging, requires specialized skills | Relatively easy to repair and maintain |

Introduction to Aerospace Materials

Composite materials in aerospace offer superior strength-to-weight ratios compared to aluminum alloys, enabling enhanced fuel efficiency and payload capacity. Aluminum alloys, traditionally used for their excellent machinability and corrosion resistance, are gradually being supplemented or replaced by advanced composites like carbon fiber-reinforced polymers. The aerospace industry increasingly favors composites for critical airframe components due to their fatigue resistance and design flexibility.

Overview of Composite Materials

Composite materials consist of two or more distinct substances combined to achieve superior strength-to-weight ratios and corrosion resistance compared to aluminum alloys. Common composites include carbon fiber-reinforced polymers, which offer high stiffness and fatigue resistance essential for aerospace and automotive applications. These materials provide tailored mechanical properties through controlled fiber orientation and matrix selection, resulting in enhanced performance over traditional aluminum alloys in specific engineering scenarios.

Overview of Aluminum Alloys

Aluminum alloys consist primarily of aluminum combined with elements such as copper, magnesium, silicon, and zinc to enhance strength, corrosion resistance, and machinability. These alloys are widely used in aerospace, automotive, and construction industries due to their lightweight and high strength-to-weight ratio. Compared to composite materials, aluminum alloys offer excellent thermal conductivity and ease of recycling, making them a sustainable choice for many engineering applications.

Mechanical Properties Comparison

Composite materials typically exhibit higher specific strength and stiffness compared to aluminum alloys, making them ideal for applications requiring lightweight and high-performance mechanical properties. Aluminum alloys offer superior ductility and impact resistance, which contribute to better energy absorption and durability under dynamic loading conditions. The choice between composites and aluminum alloys depends on balancing factors such as tensile strength, fatigue resistance, and weight savings tailored to specific engineering requirements.

Weight and Structural Efficiency

Composite materials typically offer a significantly lower weight compared to aluminum alloys, enhancing fuel efficiency and payload capacity in aerospace and automotive applications. Their high strength-to-weight ratio results in superior structural efficiency, providing equivalent or greater load-bearing capacity while minimizing mass. Aluminum alloys, although lightweight, usually have higher density and lower stiffness, making composites the preferred choice for weight-sensitive and performance-driven designs.

Corrosion Resistance and Durability

Composite materials exhibit superior corrosion resistance compared to aluminum alloys, as they are inherently immune to rust and chemical degradation. Aluminum alloys, while durable, are prone to oxidation and require protective coatings to prevent corrosion, especially in marine or acidic environments. The enhanced durability of composites under harsh conditions makes them ideal for applications demanding long-term resistance to environmental factors.

Manufacturing and Fabrication Processes

Composite materials are manufactured through processes such as lay-up, filament winding, and resin transfer molding, which allow for complex shapes and tailored mechanical properties with minimized weight. Aluminum alloys undergo casting, extrusion, forging, and machining, offering high strength-to-weight ratios and excellent machinability but limited design flexibility compared to composites. Fabrication of composites requires curing under controlled temperature and pressure, while aluminum alloy parts often rely on heat treatment and welding techniques to achieve desired mechanical characteristics.

Cost Analysis and Economic Considerations

Composite materials often have higher upfront costs due to expensive raw materials and complex manufacturing processes, while aluminum alloys benefit from established production methods and lower initial expenses. Life-cycle cost analysis reveals composites offer long-term savings through reduced maintenance, corrosion resistance, and weight-related fuel efficiency, especially in aerospace and automotive industries. Economic considerations include tooling costs, production volume, and recyclability, where aluminum alloys generally have cost advantages in high-volume applications due to better-established recycling infrastructure.

Application Examples in Aircraft Structures

Composite materials are increasingly used in aircraft structures such as fuselage panels, wing skins, and tail sections due to their high strength-to-weight ratio and corrosion resistance. Aluminum alloys remain prevalent in structural components like frames, bulkheads, and landing gear because of their excellent machinability and fatigue resistance. The Boeing 787 Dreamliner and Airbus A350 extensively utilize composites to reduce weight and improve fuel efficiency, whereas traditional aluminum alloys are often favored in older models and areas requiring higher impact toughness.

Future Trends in Aerospace Material Selection

Composite materials are increasingly favored over aluminum alloys in aerospace for their superior strength-to-weight ratio and corrosion resistance, driving advancements in fuel efficiency and performance. Emerging trends highlight the integration of nanomaterials and enhanced resin systems to improve durability and damage tolerance in composites. Lightweight aluminum alloys continue evolving with improved fatigue resistance and recyclability, but composite dominance is expected as manufacturers prioritize sustainability and innovative structural designs.

Specific strength

Composite materials exhibit higher specific strength compared to aluminum alloys, making them ideal for lightweight structural applications.

Fatigue resistance

Composite materials exhibit superior fatigue resistance compared to aluminum alloys, enabling longer service life and enhanced durability in cyclic stress applications.

Corrosion susceptibility

Composite materials exhibit significantly lower corrosion susceptibility compared to aluminum alloys, making them more suitable for environments prone to moisture and chemical exposure.

Delamination

Composite materials exhibit higher risks of delamination compared to aluminum alloys due to their layered structure and weaker interlaminar bonding.

Weight optimization

Composite materials offer significant weight optimization over aluminum alloys by providing higher strength-to-weight ratios and enhanced design flexibility for lightweight structural applications.

Galvanic corrosion

Composite materials exhibit significantly lower susceptibility to galvanic corrosion compared to aluminum alloys due to their non-metallic matrix, which prevents the formation of electrochemical cells.

Stiffness-to-weight ratio

Composite materials exhibit a higher stiffness-to-weight ratio compared to aluminum alloys, making them ideal for lightweight structural applications requiring superior rigidity.

Impact damage tolerance

Composite materials generally exhibit higher impact damage tolerance than aluminum alloys due to their superior energy absorption and damage containment properties.

Manufacturing anisotropy

Composite materials exhibit significantly lower manufacturing anisotropy compared to aluminum alloys, resulting in more consistent mechanical properties and enhanced performance in aerospace and automotive applications.

Repairability

Composite materials typically require specialized repair techniques and longer curing times, whereas aluminum alloys allow for quicker, more straightforward repairs using conventional metalworking tools.

composite material vs aluminum alloy Infographic

njnir.com

njnir.com