Vertical launch systems provide rapid deployment and reduced infrastructure footprint by launching rockets straight upward, optimizing thrust against gravity for efficient orbit insertion. Horizontal launch techniques, commonly used by spaceplanes, enable runway-based operations with reusable vehicles and potential cost savings through aircraft-like turnaround times. Both methods present unique challenges in propulsion dynamics and structural design, influencing mission profiles and payload capabilities in aerospace engineering.

Table of Comparison

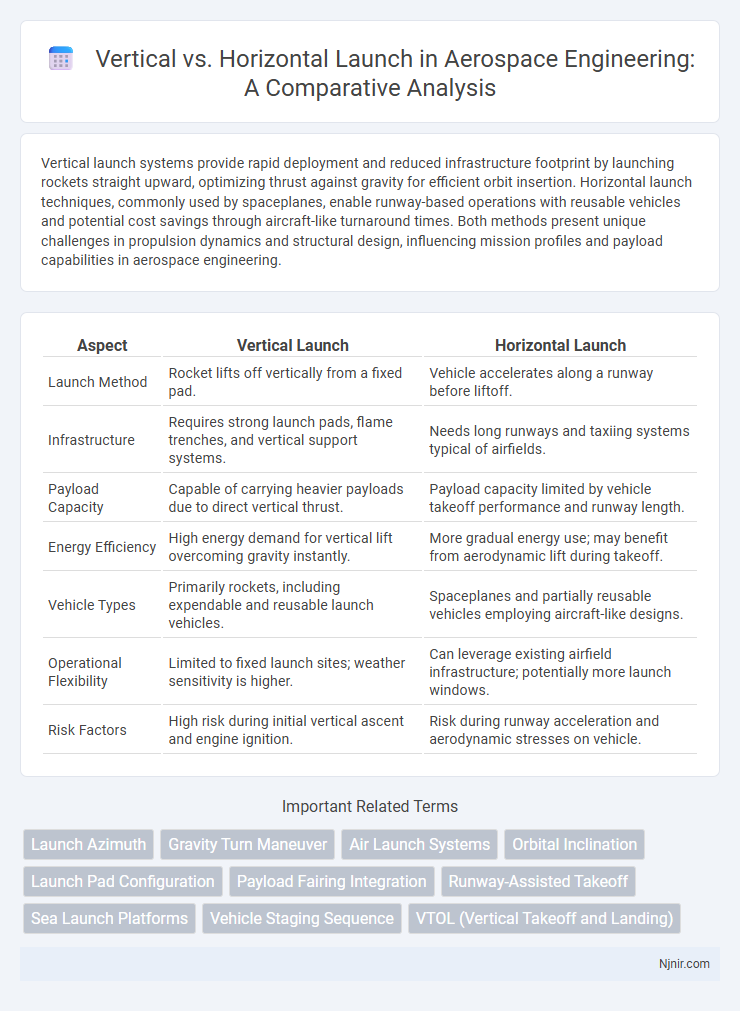

| Aspect | Vertical Launch | Horizontal Launch |

|---|---|---|

| Launch Method | Rocket lifts off vertically from a fixed pad. | Vehicle accelerates along a runway before liftoff. |

| Infrastructure | Requires strong launch pads, flame trenches, and vertical support systems. | Needs long runways and taxiing systems typical of airfields. |

| Payload Capacity | Capable of carrying heavier payloads due to direct vertical thrust. | Payload capacity limited by vehicle takeoff performance and runway length. |

| Energy Efficiency | High energy demand for vertical lift overcoming gravity instantly. | More gradual energy use; may benefit from aerodynamic lift during takeoff. |

| Vehicle Types | Primarily rockets, including expendable and reusable launch vehicles. | Spaceplanes and partially reusable vehicles employing aircraft-like designs. |

| Operational Flexibility | Limited to fixed launch sites; weather sensitivity is higher. | Can leverage existing airfield infrastructure; potentially more launch windows. |

| Risk Factors | High risk during initial vertical ascent and engine ignition. | Risk during runway acceleration and aerodynamic stresses on vehicle. |

Introduction to Launch Methods in Aerospace Engineering

Vertical launch and horizontal launch represent two primary aerospace engineering methods for deploying spacecraft or rockets. Vertical launch involves ascending directly upward from a launchpad, optimizing thrust-to-weight ratio and allowing for rapid clearance of dense atmospheric layers. Horizontal launch, often used by spaceplanes and some air-launched rockets, benefits from initial aerodynamic lift and can reduce fuel consumption during early flight phases by leveraging runway or air carrier assistance.

Defining Vertical Launch Systems

Vertical Launch Systems (VLS) are missile launching platforms where missiles are fired vertically from ships or land-based silos, allowing for rapid, 360-degree target engagement without the need to reposition the launcher. Unlike horizontal launch methods that require missile orientation toward the target prior to launch, VLS enables quicker reaction times and increased salvo fire capabilities, which are critical in modern naval warfare and air defense systems. This technology optimizes space on vessels and enhances operational efficiency by allowing multiple missile types to be stored and launched from a single, compact module.

Understanding Horizontal Launch Approaches

Horizontal launch approaches utilize runways or smooth surfaces for aircraft or rockets to gain initial velocity, enhancing control and stability during takeoff. This method is often favored in spaceplanes and reusable launch systems where aerodynamic lift aids in efficient ascent and reduced fuel consumption. Understanding horizontal launch techniques reveals benefits like cost-effectiveness, reduced structural stress, and greater flexibility for payload deployment.

Key Design Differences: Vertical vs. Horizontal Launch

Vertical launch systems utilize a vertical missile canister or silo, enabling rapid 360-degree targeting and minimized launch footprints, ideal for constrained naval and land platforms. Horizontal launch designs involve missiles being ejected or propelled from a horizontal tube or rail, requiring larger clearance and offering easier maintenance access but limited directional firing arcs. The decision between vertical and horizontal launch hinges on factors such as space constraints, mission versatility, and platform integration complexity.

Advantages of Vertical Launch in Aerospace Applications

Vertical launch systems in aerospace offer significant advantages including the ability to save ground space and reduce infrastructure complexity compared to horizontal launch pads. They enable rapid multi-directional deployment and improve payload protection during launch by minimizing aerodynamic stress. Enhanced flexibility for launch trajectory and easier integration with modular rocket designs make vertical launch ideal for versatile space missions.

Benefits of Horizontal Launch Systems

Horizontal launch systems enable aircraft to take off and land on conventional runways, allowing for flexible operational deployment and reduced infrastructure costs compared to vertical launch platforms. These systems improve payload capacity and fuel efficiency by eliminating the need for powerful vertical lift components, thereby enhancing overall mission range and performance. Integration with existing airport facilities supports rapid turnaround and maintenance, increasing sortie rates and reducing deployment time.

Cost Comparison: Vertical vs. Horizontal Launch

Vertical launch systems typically incur higher initial development and infrastructure costs due to the complexity of rocket design and specialized launch pads. Horizontal launches, often utilizing aircraft as carriers, can reduce ground infrastructure expenses and allow for greater reuse of launch equipment, which lowers operational costs. Over time, the cost efficiency of horizontal launches tends to improve with advancements in air-launched vehicle technology and operational flexibility.

Performance and Payload Considerations

Vertical launch systems offer superior payload capacity due to efficient use of thrust vectors and reduced aerodynamic drag during liftoff, making them ideal for heavy or bulky payloads. Horizontal launch vehicles benefit from runway-based launch infrastructure, which can lower operational costs and enhance reusability but may impose limits on payload size and mass due to aerodynamic constraints during takeoff. Performance trade-offs depend on mission profiles, with vertical launches excelling in maximizing payload-to-orbit ratios and horizontal launches favoring rapid turnaround and flexible launch operations.

Notable Aerospace Missions and Launch System Choices

Notable aerospace missions such as SpaceX's Starship and NASA's Space Shuttle illustrate distinct choices between vertical and horizontal launch systems, reflecting mission-specific requirements and technological advancements. Vertical launch systems dominate heavy payload deployment and interplanetary missions due to their efficient thrust-to-weight ratio and rapid ascent capabilities, exemplified by missions like Apollo and Falcon 9. Horizontal launch systems, significant in reusable spacecraft like Boeing's X-37B and the Space Shuttle, enable runway landings and enhanced reusability, influencing design decisions for long-duration, low Earth orbit missions.

Future Trends in Launch Technology and Direction

Future trends in launch technology emphasize vertical launch systems for their cost-efficiency and reusability, driven by companies like SpaceX and Blue Origin advancing rapid turnaround and fuel optimization. Horizontal launch methods, leveraging aircraft like Virgin Orbit's LauncherOne, offer flexibility in launch locations and altitude advantages, promoting responsiveness for small satellite deployment. Hybrid approaches combining vertical and horizontal technologies are emerging to maximize payload versatility and reduce infrastructure demands in next-generation space access solutions.

Launch Azimuth

Vertical launch systems enable a wider and more flexible launch azimuth range compared to horizontal launch systems, enhancing mission trajectory options and orbital insertion precision.

Gravity Turn Maneuver

Vertical launch maximizes initial thrust alignment with gravity, enabling a smoother gravity turn maneuver that efficiently transitions the rocket's trajectory from vertical ascent to horizontal orbital insertion.

Air Launch Systems

Air launch systems employ vertical launch methods from airborne platforms to achieve greater fuel efficiency and flexibility compared to traditional horizontal ground launches.

Orbital Inclination

Vertical launch systems enable more flexible orbital inclination adjustments by allowing rockets to ascend directly from the launch pad, while horizontal launch methods typically require air-launch platforms that limit initial trajectory options and thus orbital inclination versatility.

Launch Pad Configuration

Vertical launch pads feature a stationary platform with exhaust deflectors for upward rocket ignition, while horizontal launch pads utilize a horizontal rail or gantry system to support and transport the rocket to a vertical position before liftoff.

Payload Fairing Integration

Vertical launch systems enable more streamlined payload fairing integration by facilitating easier encapsulation and separation mechanisms compared to the complex aerodynamic and structural challenges in horizontal launch configurations.

Runway-Assisted Takeoff

Runway-assisted horizontal launch enables aircraft to achieve optimal lift and speed using the runway length, contrasting with vertical launch systems that rely on thrust vectoring without runway dependence.

Sea Launch Platforms

Vertical launch sea platforms offer faster missile deployment and enhanced payload capacity compared to horizontal launch systems, which require more complex handling and longer preparation times.

Vehicle Staging Sequence

Vertical launch vehicles typically utilize sequential multi-stage separation from bottom to top during ascent, whereas horizontal launch systems often involve rocket stages igniting sequentially while maintaining forward velocity on a runway.

VTOL (Vertical Takeoff and Landing)

VTOL technology enables aircraft to perform vertical takeoff and landing without runways, providing enhanced operational flexibility compared to horizontal launch systems requiring runway space.

Vertical Launch vs Horizontal Launch Infographic

njnir.com

njnir.com