Liftbody designs generate lift primarily through the shape of the vehicle's body, resulting in improved aerodynamic efficiency and better fuel economy during atmospheric flight. Blunt body configurations prioritize thermal protection by presenting a larger surface area to absorb and dissipate heat during reentry, enhancing structural safety. Comparing both, liftbodies excel in maneuverability and glide range, while blunt bodies offer superior heat shielding critical for high-speed atmospheric descent.

Table of Comparison

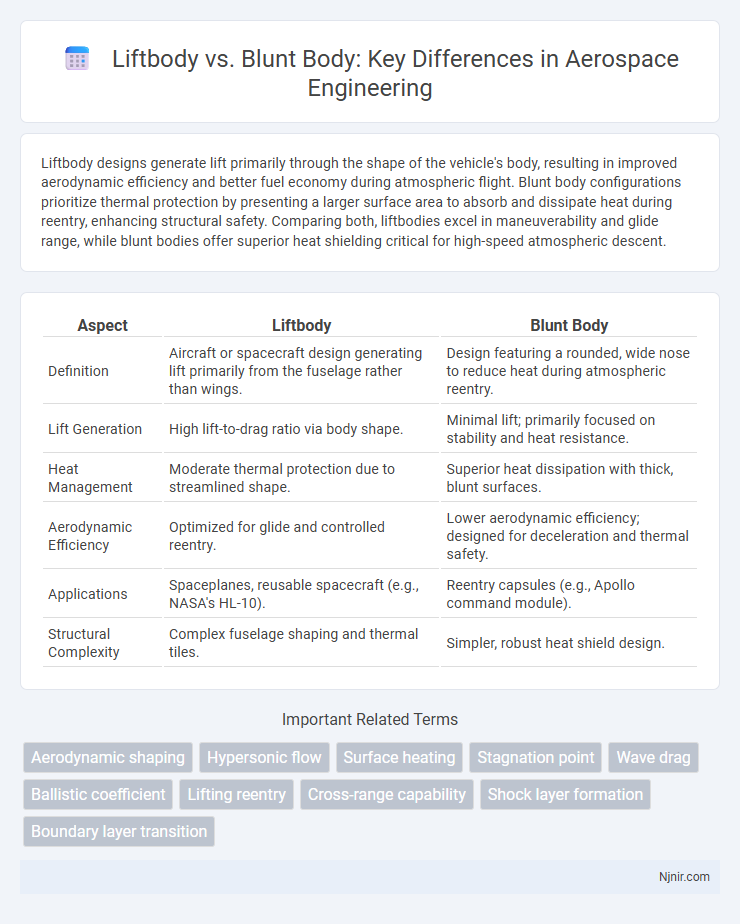

| Aspect | Liftbody | Blunt Body |

|---|---|---|

| Definition | Aircraft or spacecraft design generating lift primarily from the fuselage rather than wings. | Design featuring a rounded, wide nose to reduce heat during atmospheric reentry. |

| Lift Generation | High lift-to-drag ratio via body shape. | Minimal lift; primarily focused on stability and heat resistance. |

| Heat Management | Moderate thermal protection due to streamlined shape. | Superior heat dissipation with thick, blunt surfaces. |

| Aerodynamic Efficiency | Optimized for glide and controlled reentry. | Lower aerodynamic efficiency; designed for deceleration and thermal safety. |

| Applications | Spaceplanes, reusable spacecraft (e.g., NASA's HL-10). | Reentry capsules (e.g., Apollo command module). |

| Structural Complexity | Complex fuselage shaping and thermal tiles. | Simpler, robust heat shield design. |

Introduction to Aerospace Body Designs

Liftbody designs enhance aerodynamic efficiency by generating lift primarily from the fuselage shape, reducing the reliance on wings and improving fuel economy in spacecraft and high-speed aircraft. Blunt body designs feature rounded, less streamlined shapes that increase drag and heat dissipation, commonly used in re-entry vehicles to protect against intense atmospheric heating. Understanding the trade-offs between lift generation and thermal protection is crucial in aerospace body design for optimizing performance and safety.

Defining Liftbody and Blunt Body Concepts

Liftbody designs integrate the fuselage and wing structures to generate aerodynamic lift, enhancing lift-to-drag ratio and fuel efficiency. Blunt body configurations feature rounded, non-streamlined shapes that minimize heat buildup during high-speed reentry but increase drag. Understanding liftbody focuses on aerodynamic lift generation, whereas blunt body emphasizes thermal protection and stability during atmospheric entry.

Aerodynamic Principles: Liftbody vs Blunt Body

Liftbody designs generate significant aerodynamic lift through the shape of the fuselage, enhancing stability and reducing the reliance on wings for lift in aerospace applications. Blunt body shapes prioritize drag reduction by managing shock waves and controlling heat distribution, which is critical during high-speed re-entry and hypersonic flight. The aerodynamic principles of liftbodies involve smooth airflow manipulation to maximize lift-to-drag ratios, whereas blunt bodies focus on minimizing thermal loads and aerodynamic drag with a wider, more rounded frontal area.

Structural Considerations in Body Design

Liftbody designs emphasize smooth, aerodynamically contoured surfaces that distribute structural loads evenly, enhancing overall strength while minimizing weight. Blunt body structures prioritize reinforced frontal sections to withstand high impact forces and improve crashworthiness, often resulting in increased material thickness and weight. Optimizing structural integrity in liftbody shapes demands advanced composite materials and load-path analyses, whereas blunt bodies rely on traditional high-strength alloys and robust frame constructions for durability.

Thermal Management and Heat Protection

Liftbody designs generate aerodynamic lift through their shape, enabling more efficient thermal management by distributing heat over a larger surface area during atmospheric reentry. Blunt body configurations rely on a thicker shock layer to blunt incoming heat, resulting in higher peak thermal loads but simpler heat protection systems such as ablative shields or reinforced carbon composites. Liftbody vehicles typically utilize advanced thermal protection materials and active cooling techniques to handle distributed heat flux, whereas blunt bodies prioritize robust passive barriers to withstand intense localized heating.

Performance in Atmospheric Re-entry

Liftbody designs excel in atmospheric re-entry by generating significant lift, enabling controlled descent trajectories and reduced thermal loads on the vehicle's surface. Blunt body shapes prioritize drag and shockwave formation to dissipate heat rapidly, resulting in simpler thermal protection but less maneuverability during re-entry. The trade-off between aerodynamic control and heat management defines the performance differences, with liftbodies offering precision landing capabilities and blunt bodies enabling robust heat shielding.

Stability and Control Characteristics

Liftbody designs provide improved stability and control through their aerodynamic shapes that generate lift without traditional wings, enhancing maneuverability during reentry and hypersonic flight. Blunt body configurations prioritize thermal protection and bluntness to reduce heat load, sacrificing some aerodynamic stability and requiring additional control surfaces or thrust vectoring for effective maneuvering. Stability in liftbody vehicles is inherently more balanced due to their distributed lift forces, while blunt bodies rely heavily on external control inputs to maintain trajectory and attitude.

Applications in Modern Aerospace Vehicles

Liftbody designs optimize aerodynamic efficiency by generating lift through the vehicle's body without traditional wings, making them ideal for spacecraft reentry and reusable spaceplanes such as NASA's HL-10 and Boeing X-37. Blunt body shapes prioritize thermal protection and stability at hypersonic speeds, commonly used in reentry capsules like the Apollo Command Module and modern crewed capsules such as SpaceX Dragon. Modern aerospace vehicles leverage liftbody configurations for enhanced maneuverability and range, while blunt bodies remain crucial for robust heat shielding during atmospheric reentry.

Historical Evolution of Body Shapes

Liftbody and blunt body designs emerged from the aerospace industry's quest for efficient reentry vehicles during the mid-20th century. The blunt body concept, pioneered by Theodore von Karman, emphasized aerodynamic heating reduction via a rounded, wide nose, influencing early spacecraft like Mercury and Apollo. Liftbody shapes, developed in the 1960s, prioritized generating lift without wings, leading to experimental aircraft such as NASA's HL-10, which informed modern spaceplane aerodynamics and atmospheric reentry techniques.

Future Trends in Aerospace Body Engineering

Future trends in aerospace body engineering emphasize the integration of liftbody designs to enhance aerodynamic efficiency and fuel savings, leveraging their smoother contours for reduced drag compared to traditional blunt bodies. Advanced materials such as carbon composites and adaptive morphing surfaces enable optimized lift-to-drag ratios, directly impacting spacecraft reentry and hypersonic flight performance. Innovations in computational fluid dynamics and AI-driven design tools further accelerate the development of hybrid configurations, blending liftbody and blunt body characteristics to achieve superior thermal protection and payload capacity.

Aerodynamic shaping

Liftbody designs optimize aerodynamic shaping by generating lift through the vehicle's entire body, enhancing fuel efficiency and stability, while blunt body shapes prioritize structural robustness and internal volume, resulting in higher drag and reduced aerodynamic efficiency.

Hypersonic flow

Liftbody designs generate greater hypersonic flow stability and reduced drag compared to blunt body shapes, enhancing maneuverability and thermal protection during high-speed atmospheric reentry.

Surface heating

Liftbody designs reduce surface heating more effectively than blunt body shapes by promoting smoother airflow and lower aerodynamic drag during high-speed flight.

Stagnation point

The stagnation point on a liftbody generates higher pressure and lower drag compared to a blunt body, enhancing aerodynamic efficiency and stability during flight.

Wave drag

Liftbody designs reduce wave drag more effectively than blunt body shapes by promoting smoother airflow and minimizing shockwave formation at transonic and supersonic speeds.

Ballistic coefficient

Liftbody designs offer lower ballistic coefficients compared to blunt body shapes, resulting in increased atmospheric drag and enhanced deceleration during re-entry.

Lifting reentry

Liftbody reentry vehicles generate aerodynamic lift through their shape to achieve controlled descent and precise landing, whereas blunt body designs rely on blunt contours to create shockwaves that dissipate heat but offer minimal lift during reentry.

Cross-range capability

Liftbody designs offer superior cross-range capability compared to blunt body shapes due to their enhanced aerodynamic lift and maneuverability.

Shock layer formation

Liftbody designs generate thinner, more detached shock layers reducing aerodynamic drag compared to blunt bodies, which produce thicker, stronger shock layers with higher drag and heat transfer rates.

Boundary layer transition

Liftbody designs promote earlier boundary layer transition from laminar to turbulent flow, reducing drag compared to blunt body shapes that maintain thicker laminar boundary layers and experience higher pressure drag.

Liftbody vs Blunt body Infographic

njnir.com

njnir.com