Additive manufacturing enables the production of complex aerospace components with reduced material waste and shorter lead times compared to conventional machining. Its layer-by-layer fabrication allows for intricate geometries and lightweight structures unattainable through subtractive processes. However, conventional machining still provides superior surface finishes and dimensional accuracy essential for critical aerospace parts.

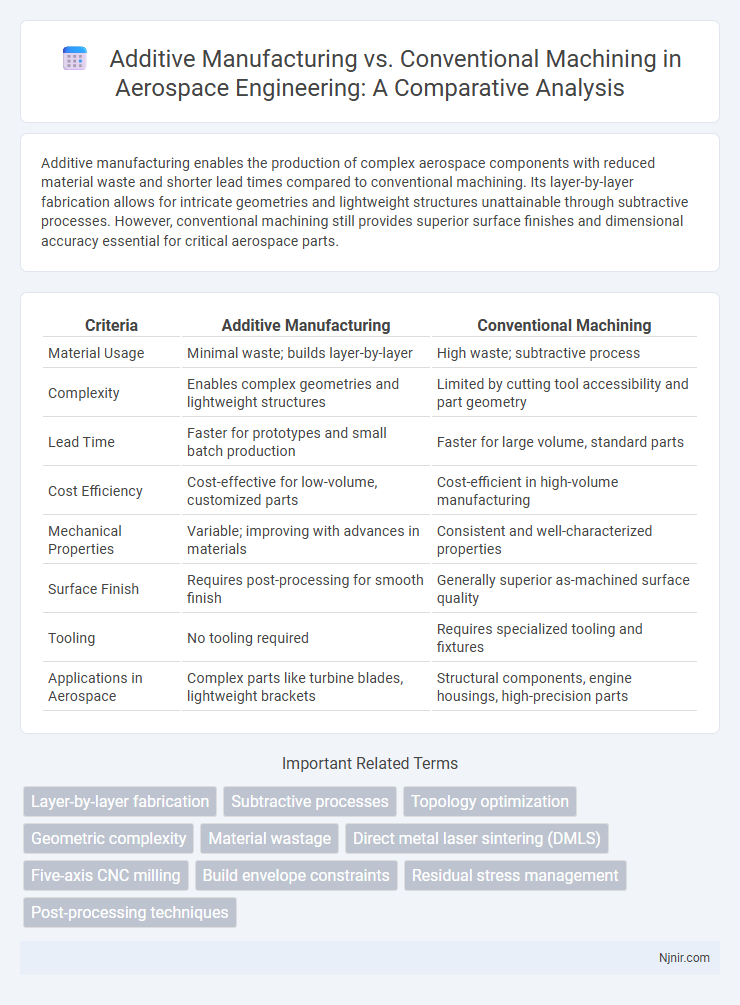

Table of Comparison

| Criteria | Additive Manufacturing | Conventional Machining |

|---|---|---|

| Material Usage | Minimal waste; builds layer-by-layer | High waste; subtractive process |

| Complexity | Enables complex geometries and lightweight structures | Limited by cutting tool accessibility and part geometry |

| Lead Time | Faster for prototypes and small batch production | Faster for large volume, standard parts |

| Cost Efficiency | Cost-effective for low-volume, customized parts | Cost-efficient in high-volume manufacturing |

| Mechanical Properties | Variable; improving with advances in materials | Consistent and well-characterized properties |

| Surface Finish | Requires post-processing for smooth finish | Generally superior as-machined surface quality |

| Tooling | No tooling required | Requires specialized tooling and fixtures |

| Applications in Aerospace | Complex parts like turbine blades, lightweight brackets | Structural components, engine housings, high-precision parts |

Introduction to Additive Manufacturing and Conventional Machining

Additive manufacturing builds objects layer by layer using digital models, enabling complex geometries and material efficiency that conventional machining cannot easily achieve. Conventional machining removes material from a solid block through subtractive processes like milling, turning, or drilling, offering high precision and surface finish but generating more waste. Both methods serve distinct manufacturing needs, with additive manufacturing excelling in rapid prototyping and customization, while conventional machining remains preferred for high-volume, precise metal parts.

Principles and Processes in Aerospace Fabrication

Additive manufacturing in aerospace fabrication builds components layer by layer using digital models, enabling complex geometries and material efficiency not achievable with conventional machining, which removes material through cutting or drilling processes. The principles of additive manufacturing rely on techniques such as selective laser melting and electron beam melting to fuse metal powders, while conventional machining employs subtractive methods like milling and turning to shape blocks of metal. This shift in processes allows aerospace manufacturers to reduce waste, decrease lead times, and produce optimized parts tailored to high-performance requirements.

Material Compatibility and Performance Considerations

Additive manufacturing enables the use of complex geometries with a wide range of thermoplastics, metals, and composites, allowing for tailored material properties that improve performance in lightweight and high-strength applications. Conventional machining supports an extensive variety of metals and alloys, often yielding superior surface finish and tighter tolerances but involves material waste and limitations in fabricating intricate designs. Performance considerations include additive manufacturing's advantage in producing customized, functionally graded materials, while conventional machining excels in high-precision components requiring consistent mechanical properties and surface integrity.

Design Flexibility and Geometric Complexity

Additive manufacturing enables unparalleled design flexibility by building components layer-by-layer, allowing for complex internal structures and intricate geometries unachievable through subtractive processes. Conventional machining is limited by tool access and material removal constraints, restricting the creation of highly detailed or hollow parts. This advantage of additive manufacturing facilitates lightweight designs and customized solutions critical in aerospace and medical industries.

Production Speed and Turnaround Times

Additive manufacturing offers significantly faster production speed for complex and customized parts by building layer-by-layer directly from digital models, reducing the need for tooling and setup times common in conventional machining. Conventional machining generally requires longer turnaround times due to material removal processes, fixture setups, and multiple tooling changes, especially for intricate geometries. For prototyping and low to medium volume production, additive manufacturing provides a quicker path from design to final product, whereas conventional machining remains efficient for high-volume runs of standardized components.

Cost-Efficiency and Resource Utilization

Additive manufacturing minimizes material waste by building parts layer-by-layer, enhancing resource utilization compared to subtractive methods in conventional machining that remove excess material. Cost-efficiency improves in additive manufacturing for low-volume or complex geometry production due to reduced tooling costs and shorter lead times. In contrast, conventional machining remains more cost-effective for high-volume runs with simpler shapes, leveraging economies of scale and faster cycle times.

Structural Integrity and Component Reliability

Additive manufacturing enhances structural integrity by enabling complex geometries with optimized material distribution, reducing stress concentrators common in conventional machining. Component reliability improves through layer-by-layer fabrication, minimizing residual stresses and defects often introduced by subtractive methods. Metal additive processes, such as selective laser melting, produce parts with comparable or superior fatigue resistance compared to traditional machining.

Sustainability and Waste Reduction

Additive manufacturing significantly enhances sustainability by minimizing material waste, using only the necessary amount of raw material layer by layer, unlike conventional machining which often removes substantial material as scrap. This process reduces energy consumption and lowers carbon emissions by streamlining production and enabling localized manufacturing. Lifecycle assessments reveal that additive manufacturing supports circular economy principles through improved resource efficiency and reduced environmental impact.

Current Aerospace Applications and Case Studies

Additive manufacturing in aerospace enables the production of complex, lightweight components such as fuel nozzles and turbine blades, reducing material waste and lead times compared to conventional machining. Case studies from companies like GE Aviation and Boeing demonstrate enhanced design flexibility and performance improvements by using additive techniques for engine parts and structural components. Conventional machining remains essential for high-precision finishes and large-scale metal parts, but hybrid approaches combining additive and subtractive manufacturing are increasingly adopted to optimize aerospace production efficiency and cost.

Future Trends and Technological Advancements

Additive manufacturing is rapidly advancing with innovations like multi-material printing and faster, high-resolution processes that enable complex geometries unattainable by conventional machining. Integration of AI and machine learning optimizes print parameters and enhances quality control, while hybrid manufacturing systems combine additive and subtractive techniques for improved efficiency. The expansion of metal additive manufacturing and sustainable materials further drives adoption across aerospace, automotive, and medical industries, signaling a shift toward more flexible and sustainable production methods.

Layer-by-layer fabrication

Additive manufacturing creates complex geometries through precise layer-by-layer fabrication, contrasting with conventional machining that removes material from a solid block.

Subtractive processes

Subtractive processes in conventional machining remove material from a solid block using cutting tools, whereas additive manufacturing builds parts layer by layer, minimizing material waste and enabling complex geometries.

Topology optimization

Topology optimization enhances additive manufacturing by enabling complex, weight-efficient designs unachievable through conventional machining constraints.

Geometric complexity

Additive manufacturing enables the creation of highly complex geometries unachievable by conventional machining due to its layer-by-layer construction process.

Material wastage

Additive manufacturing significantly reduces material wastage by building components layer-by-layer only where needed, unlike conventional machining which removes excess material from a solid block resulting in higher scrap rates.

Direct metal laser sintering (DMLS)

Direct Metal Laser Sintering (DMLS) enables complex geometries and material efficiency unattainable by conventional machining, significantly reducing waste and production time in additive manufacturing.

Five-axis CNC milling

Five-axis CNC milling enhances conventional machining by enabling complex geometries and higher precision, while additive manufacturing offers greater design flexibility and material efficiency through layer-by-layer fabrication.

Build envelope constraints

Additive manufacturing offers larger and more complex build envelopes with fewer geometric constraints compared to conventional machining, which is limited by tool accessibility and workpiece size.

Residual stress management

Additive manufacturing enables precise residual stress management through layer-by-layer thermal control, reducing distortion compared to conventional machining's stress concentration from material removal.

Post-processing techniques

Post-processing techniques in additive manufacturing often involve support removal, surface polishing, and heat treatment, whereas conventional machining primarily requires deburring, grinding, and surface finishing to achieve desired tolerances and surface quality.

additive manufacturing vs conventional machining Infographic

njnir.com

njnir.com