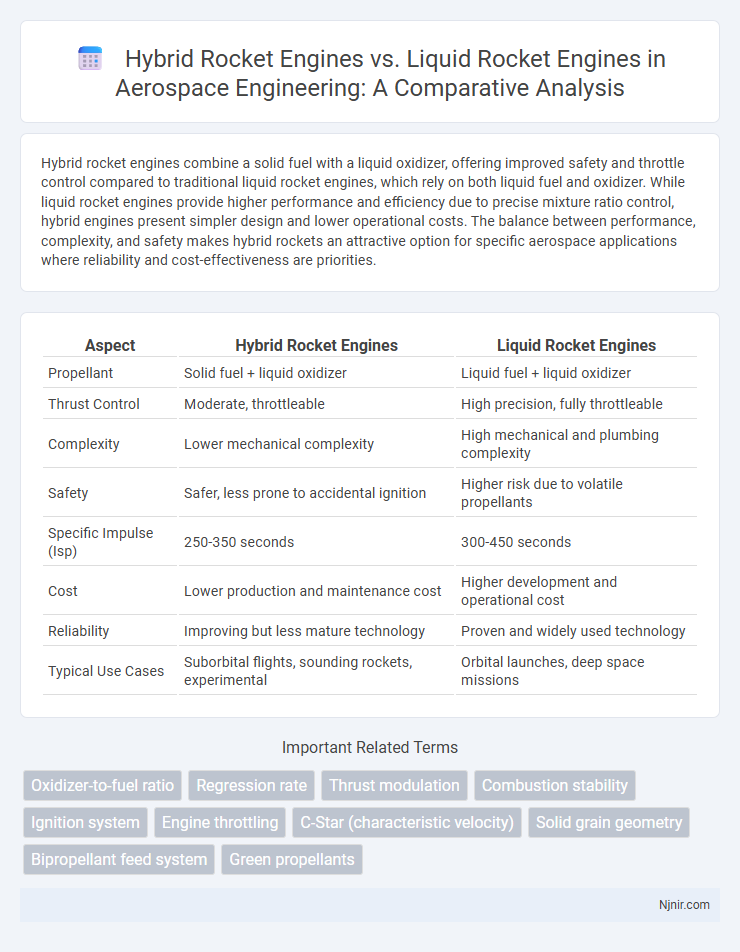

Hybrid rocket engines combine a solid fuel with a liquid oxidizer, offering improved safety and throttle control compared to traditional liquid rocket engines, which rely on both liquid fuel and oxidizer. While liquid rocket engines provide higher performance and efficiency due to precise mixture ratio control, hybrid engines present simpler design and lower operational costs. The balance between performance, complexity, and safety makes hybrid rockets an attractive option for specific aerospace applications where reliability and cost-effectiveness are priorities.

Table of Comparison

| Aspect | Hybrid Rocket Engines | Liquid Rocket Engines |

|---|---|---|

| Propellant | Solid fuel + liquid oxidizer | Liquid fuel + liquid oxidizer |

| Thrust Control | Moderate, throttleable | High precision, fully throttleable |

| Complexity | Lower mechanical complexity | High mechanical and plumbing complexity |

| Safety | Safer, less prone to accidental ignition | Higher risk due to volatile propellants |

| Specific Impulse (Isp) | 250-350 seconds | 300-450 seconds |

| Cost | Lower production and maintenance cost | Higher development and operational cost |

| Reliability | Improving but less mature technology | Proven and widely used technology |

| Typical Use Cases | Suborbital flights, sounding rockets, experimental | Orbital launches, deep space missions |

Introduction to Rocket Propulsion Technologies

Hybrid rocket engines combine a solid fuel with a liquid or gaseous oxidizer, offering controllability and safety advantages over liquid rocket engines, which use liquid fuel and oxidizer stored separately. Liquid rocket engines provide higher performance due to precise thrust modulation and efficient combustion but involve complex plumbing and cryogenic storage systems. Both technologies play crucial roles in modern aerospace propulsion, balancing trade-offs between simplicity, cost, and operational flexibility.

Fundamentals of Hybrid Rocket Engines

Hybrid rocket engines utilize a combination of solid fuel and a liquid oxidizer, offering advantages in controllability and safety over fully solid rockets. Their operation is based on the regression rate of the solid fuel grain, which determines the thrust produced as the liquid oxidizer flows and combusts on the fuel surface. Unlike liquid rocket engines, hybrids eliminate complex turbopump systems, providing simpler mechanical designs while maintaining throttleability and restart capability.

Fundamentals of Liquid Rocket Engines

Liquid rocket engines operate by injecting propellants separately into a combustion chamber where they mix and ignite, producing high-efficiency thrust through controlled combustion. These engines utilize turbopumps to deliver precise propellant flow rates, enabling adjustable thrust and restart capability during flight. The combustion process in liquid engines achieves higher specific impulse compared to hybrid rockets, making them preferred for missions requiring sustained and controllable propulsion.

Propellant Types and Selection Criteria

Hybrid rocket engines use a combination of solid fuel and liquid oxidizer, offering simplicity in fuel handling and safety advantages compared to fully liquid engines. Liquid rocket engines utilize separate liquid fuel and oxidizer, enabling precise throttle control and higher specific impulse but requiring complex plumbing and cryogenic storage. Selection of propellants depends on factors such as performance requirements, storability, cost, and mission duration, with hybrids often favored for moderate thrust and safer operations, while liquids excel in high-performance applications demanding variable thrust.

Performance Characteristics: Thrust and Efficiency

Hybrid rocket engines offer a balance of performance characteristics, providing moderate thrust with improved safety and throttling capabilities compared to liquid rocket engines. Liquid rocket engines generally deliver higher thrust and better specific impulse, translating to greater efficiency and more precise control during flight. The combination of solid fuel and liquid oxidizer in hybrid engines results in simpler design and lower cost but typically sacrifices some thrust and efficiency relative to fully liquid propulsion systems.

Safety Considerations and Risk Factors

Hybrid rocket engines offer enhanced safety by combining a solid fuel with a liquid oxidizer, reducing the risk of accidental detonation compared to fully liquid systems. Liquid rocket engines involve handling highly volatile propellants, increasing the potential for leaks and combustion instability, which poses higher operational hazards. The controlled combustion in hybrid rockets limits explosion risks, making them preferable for missions prioritizing safety and lower environmental impact.

Cost Analysis and Manufacturing Complexity

Hybrid rocket engines generally offer lower manufacturing complexity and cost compared to liquid rocket engines, as they use simpler designs combining a solid fuel grain with a liquid oxidizer, reducing the need for intricate plumbing and turbopumps. Liquid rocket engines require precision machining, complex turbopump assemblies, and extensive cooling systems, leading to higher production costs and longer manufacturing times. Cost analysis reveals hybrid engines are more economical for small to medium-sized launches, while liquid engines, despite higher upfront costs, deliver greater performance flexibility for large-scale missions.

Applications in Modern Aerospace Missions

Hybrid rocket engines offer safer operation and throttling flexibility, making them ideal for experimental launch vehicles and suborbital missions. Liquid rocket engines dominate heavy-lift and deep space missions due to their high efficiency, precise thrust control, and restart capabilities. Modern aerospace increasingly integrates both technologies to optimize mission-specific requirements, balancing cost, safety, and performance.

Recent Advances and Emerging Innovations

Recent advances in hybrid rocket engines include improved fuel grain formulations and advanced additive manufacturing techniques, enhancing combustion efficiency and thrust. Emerging innovations in liquid rocket engines highlight the development of ultra-high-performance staged combustion cycles and cryogenic propellants for greater specific impulse. Both propulsion types benefit from enhanced thrust vector control systems, enabling more precise maneuverability and mission adaptability.

Future Prospects and Industry Trends

Hybrid rocket engines offer promising future prospects due to their simplified design, lower operational costs, and enhanced safety compared to liquid rocket engines, which rely on complex plumbing and cryogenic propellants. Industry trends indicate increasing investment in hybrid propulsion for sustainable space exploration and commercial launch systems, with companies prioritizing eco-friendly propellants and modular engine components. Liquid rocket engines continue to dominate heavy-lift applications, but hybrids are positioned to disrupt small to medium payload markets through advances in thrust control and reusability.

Oxidizer-to-fuel ratio

Hybrid rocket engines achieve a more flexible oxidizer-to-fuel ratio compared to liquid rocket engines, enabling precise thrust control and improved combustion efficiency.

Regression rate

Hybrid rocket engines feature a lower and less predictable fuel regression rate compared to the consistently higher regression rate of liquid rocket engines, impacting thrust variability and combustion efficiency.

Thrust modulation

Hybrid rocket engines enable precise thrust modulation by controlling oxidizer flow, offering smoother throttle response compared to the complex valve mechanisms required for liquid rocket engines.

Combustion stability

Hybrid rocket engines often exhibit greater combustion stability compared to liquid rocket engines due to their simpler oxidizer and fuel flow paths, reducing turbulence and combustion instabilities.

Ignition system

Hybrid rocket engines feature simpler and more reliable ignition systems by combining a solid fuel with a liquid oxidizer, whereas liquid rocket engines require complex ignition mechanisms to initiate combustion of both liquid propellants.

Engine throttling

Hybrid rocket engines offer more precise engine throttling control compared to liquid rocket engines due to simpler propellant flow regulation and reduced risk of combustion instability.

C-Star (characteristic velocity)

Hybrid rocket engines typically exhibit lower C-Star values compared to liquid rocket engines due to less efficient combustion processes and propellant mixing.

Solid grain geometry

Hybrid rocket engines use solid grain geometry to optimize fuel regression rates and controllability, offering improved safety and throttling compared to traditional liquid rocket engines.

Bipropellant feed system

Hybrid rocket engines use a simpler, often pressure-fed bipropellant feed system combining solid fuel with liquid oxidizer, whereas liquid rocket engines rely on complex turbopump-driven bipropellant feed systems to inject both liquid fuel and oxidizer.

Green propellants

Hybrid rocket engines using green propellants offer enhanced environmental safety and simplified storage compared to traditional liquid rocket engines reliant on toxic fuels.

hybrid rocket engines vs liquid rocket engines Infographic

njnir.com

njnir.com