Drag reduction devices enhance aerodynamic efficiency by minimizing pressure drag and skin friction on aircraft surfaces. Vortex generators specifically improve airflow attachment by creating controlled vortices, delaying boundary layer separation and reducing wake turbulence. Compared to passive drag reduction methods, vortex generators offer targeted flow control that optimizes lift-to-drag ratios in critical flight conditions.

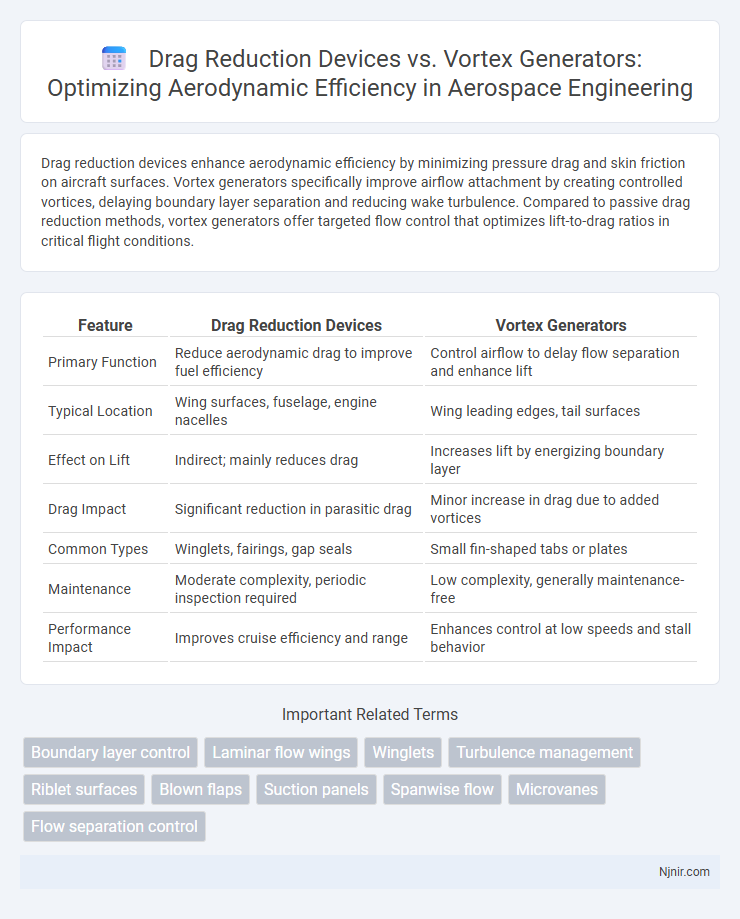

Table of Comparison

| Feature | Drag Reduction Devices | Vortex Generators |

|---|---|---|

| Primary Function | Reduce aerodynamic drag to improve fuel efficiency | Control airflow to delay flow separation and enhance lift |

| Typical Location | Wing surfaces, fuselage, engine nacelles | Wing leading edges, tail surfaces |

| Effect on Lift | Indirect; mainly reduces drag | Increases lift by energizing boundary layer |

| Drag Impact | Significant reduction in parasitic drag | Minor increase in drag due to added vortices |

| Common Types | Winglets, fairings, gap seals | Small fin-shaped tabs or plates |

| Maintenance | Moderate complexity, periodic inspection required | Low complexity, generally maintenance-free |

| Performance Impact | Improves cruise efficiency and range | Enhances control at low speeds and stall behavior |

Introduction to Drag in Aerospace Engineering

Drag reduction devices enhance aerodynamic efficiency by minimizing turbulent airflow separation and lowering pressure drag on aircraft surfaces. Vortex generators, a common drag reduction device, improve boundary layer control by creating small vortices that energize the airflow, delaying flow separation and reducing wake turbulence. Understanding the physics of drag components--pressure drag, skin friction drag, and induced drag--is essential for optimizing these devices in aerospace engineering applications.

Overview of Drag Reduction Devices

Drag reduction devices, including vortex generators, are engineered to improve aerodynamic efficiency by minimizing surface drag on vehicles and aircraft. These devices manipulate airflow to delay boundary layer separation, thereby reducing pressure drag and enhancing fuel efficiency. Common types include vortex generators, boat tails, vortex fences, and active flow control elements, each tailored to specific aerodynamic challenges.

Fundamentals of Vortex Generators

Vortex generators are small aerodynamic surfaces designed to create controlled vortices that energize the boundary layer, delaying flow separation and reducing drag on aircraft wings and turbine blades. Unlike drag reduction devices primarily aimed at minimizing resistance, vortex generators improve lift-to-drag ratio by enhancing airflow attachment and stability. Their fundamental role lies in manipulating airflow to maintain laminar flow over surfaces, thereby optimizing aerodynamic efficiency.

Comparative Analysis: Drag Reduction Devices vs Vortex Generators

Drag reduction devices, such as boat hull modifications and aerodynamic fairings, primarily minimize pressure drag by streamlining flow and reducing wake size, enhancing fuel efficiency and speed. Vortex generators, small aerodynamic surfaces placed on wings or vehicle bodies, improve boundary layer control by energizing the airflow, effectively delaying flow separation but can increase parasite drag slightly. Comparative analysis shows drag reduction devices offer broader drag minimization benefits, while vortex generators excel in maintaining aerodynamic stability and control under specific operating conditions.

Aerodynamic Principles Behind Drag Reduction

Drag reduction devices manipulate airflow to minimize pressure drag and skin friction by streamlining the vehicle shape, reducing turbulence and flow separation. Vortex generators create controlled vortices that energize the boundary layer, delaying flow separation and reducing wake size, which lowers pressure drag. Both methods enhance aerodynamic efficiency by optimizing airflow behavior, though drag reduction devices primarily smooth flow while vortex generators strategically disrupt it to maintain attached flow.

Applications of Drag Reduction Devices in Modern Aircraft

Drag reduction devices in modern aircraft improve fuel efficiency and increase range by minimizing aerodynamic resistance during flight. Vortex generators, small aerodynamic surfaces placed on wings and control surfaces, enhance boundary layer control, delaying flow separation and reducing drag while improving lift characteristics. Applications include commercial airliners, business jets, and military fighters, where both drag reduction devices and vortex generators optimize performance, stability, and fuel economy.

Role of Vortex Generators in Flow Control

Vortex generators are aerodynamic devices designed to delay flow separation by creating controlled vortices that re-energize the boundary layer, enhancing lift and reducing drag. Unlike general drag reduction devices aimed at minimizing resistance, vortex generators specifically manipulate airflow patterns to improve stability and control, particularly on wings or turbine blades. Their strategic placement influences flow separation points, leading to improved overall aerodynamic efficiency and performance.

Performance Benefits and Limitations

Drag reduction devices improve fuel efficiency by minimizing aerodynamic resistance on vehicles, often enhancing high-speed stability but may add weight or complexity to the design. Vortex generators optimize airflow by creating controlled vortices that delay flow separation, improving lift and control at lower speeds, though their effectiveness diminishes at higher velocities. Choosing between these devices depends on specific performance goals, with drag reducers suited for cruising efficiency and vortex generators benefiting maneuverability and stall characteristics.

Recent Innovations in Drag Reduction Technology

Recent innovations in drag reduction technology emphasize advanced drag reduction devices designed to enhance aerodynamic efficiency by minimizing flow separation and turbulence. Vortex generators have evolved with optimized shapes and materials, improving airflow attachment and reducing drag on aircraft and automobiles. Integration of smart materials and active flow control systems in drag reduction devices is driving new performance breakthroughs, enabling adaptive responses to varying aerodynamic conditions.

Future Trends in Aerospace Drag Management

Future trends in aerospace drag management emphasize advanced drag reduction devices that integrate adaptive materials and real-time flow control to optimize aircraft performance. Vortex generators continue evolving, incorporating smart sensor technology to dynamically manipulate boundary layer behavior for improved lift-to-drag ratios. Research focuses on combining these technologies with AI-driven aerodynamic models to achieve significant fuel efficiency and emissions reductions.

Boundary layer control

Drag reduction devices and vortex generators both enhance boundary layer control by delaying flow separation, but vortex generators specifically increase momentum exchange within the boundary layer to maintain attached flow and reduce drag effectively.

Laminar flow wings

Laminar flow wings equipped with vortex generators optimize drag reduction by strategically disrupting boundary layer flow to delay flow separation, while traditional drag reduction devices primarily focus on minimizing surface friction.

Winglets

Winglets, as advanced drag reduction devices, improve aerodynamic efficiency by mitigating wingtip vortices more effectively than traditional vortex generators, thereby reducing induced drag and enhancing fuel efficiency.

Turbulence management

Drag reduction devices minimize turbulence by streamlining airflow, while vortex generators actively manage turbulence by creating controlled vortices to enhance boundary layer stability and delay flow separation.

Riblet surfaces

Riblet surfaces effectively reduce drag by manipulating boundary layer flow, providing superior aerodynamic performance compared to conventional vortex generators.

Blown flaps

Blown flaps enhance lift and reduce drag more effectively than traditional vortex generators by actively controlling airflow momentum over the wing surface.

Suction panels

Suction panels outperform traditional vortex generators in drag reduction by actively removing boundary layer separation through controlled air extraction, enhancing aerodynamic efficiency.

Spanwise flow

Drag reduction devices improve aerodynamic efficiency by minimizing spanwise flow disturbances, whereas vortex generators enhance spanwise flow stability to delay flow separation.

Microvanes

Microvanes outperform traditional vortex generators by reducing drag more efficiently through targeted boundary layer manipulation on aircraft surfaces.

Flow separation control

Drag reduction devices minimize flow separation by streamlining airflow, while vortex generators actively control flow separation by creating vortices that energize the boundary layer and delay separation.

drag reduction devices vs vortex generators Infographic

njnir.com

njnir.com