Fiber optic sensors offer significant advantages over traditional sensors in aerospace engineering due to their lightweight, immunity to electromagnetic interference, and ability to operate in extreme environments. These sensors provide higher sensitivity and faster response times, enabling precise monitoring of structural health and performance in aircraft and spacecraft. Their integration enhances safety and efficiency by delivering real-time data for predictive maintenance and system optimization.

Table of Comparison

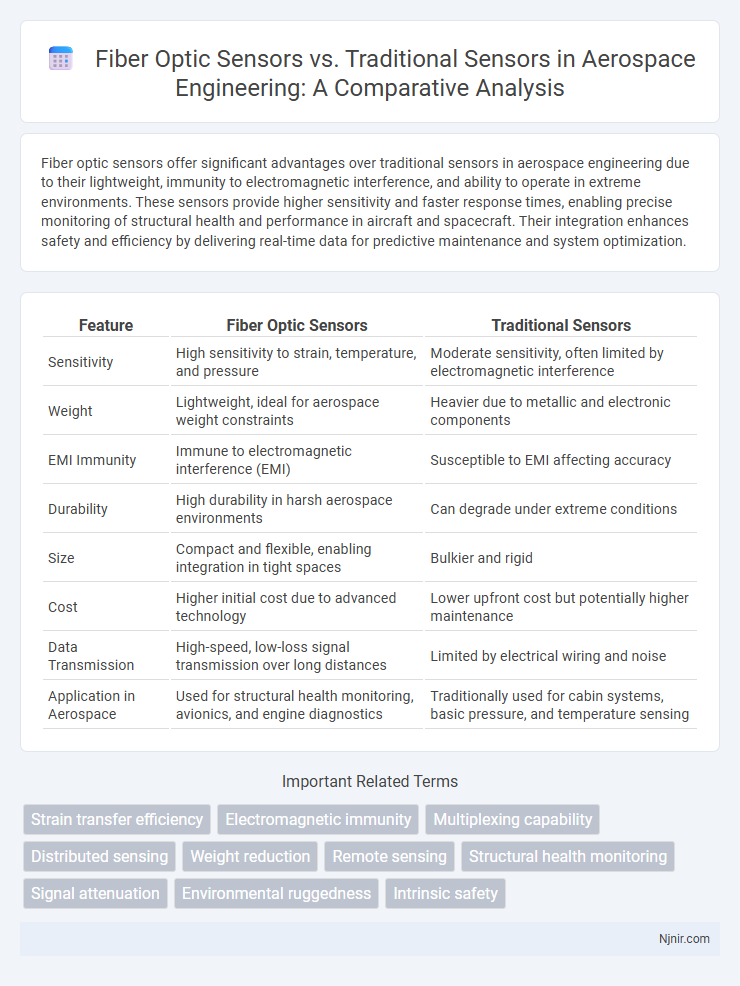

| Feature | Fiber Optic Sensors | Traditional Sensors |

|---|---|---|

| Sensitivity | High sensitivity to strain, temperature, and pressure | Moderate sensitivity, often limited by electromagnetic interference |

| Weight | Lightweight, ideal for aerospace weight constraints | Heavier due to metallic and electronic components |

| EMI Immunity | Immune to electromagnetic interference (EMI) | Susceptible to EMI affecting accuracy |

| Durability | High durability in harsh aerospace environments | Can degrade under extreme conditions |

| Size | Compact and flexible, enabling integration in tight spaces | Bulkier and rigid |

| Cost | Higher initial cost due to advanced technology | Lower upfront cost but potentially higher maintenance |

| Data Transmission | High-speed, low-loss signal transmission over long distances | Limited by electrical wiring and noise |

| Application in Aerospace | Used for structural health monitoring, avionics, and engine diagnostics | Traditionally used for cabin systems, basic pressure, and temperature sensing |

Introduction to Sensing Technologies in Aerospace

Fiber optic sensors in aerospace provide enhanced sensitivity, immunity to electromagnetic interference, and lightweight integration compared to traditional electronic sensors. These sensors utilize light transmission through optical fibers to detect strain, temperature, and pressure with high accuracy, crucial for real-time structural health monitoring and safety. Their ability to operate in harsh environments and offer multiplexing capabilities makes them superior for advanced aerospace applications.

Fundamentals of Fiber Optic Sensors

Fiber optic sensors utilize light transmission through optical fibers to detect changes in temperature, pressure, strain, and other physical parameters with high sensitivity and immunity to electromagnetic interference. Unlike traditional sensors that rely on electrical signals, fiber optic sensors operate on principles such as intensity modulation, phase modulation, and wavelength shift, enabling precise remote sensing in harsh environments. The core advantage lies in their ability to provide distributed sensing over long distances with minimal signal loss, making them ideal for structural health monitoring and industrial applications.

Overview of Traditional Sensors Used in Aerospace

Traditional sensors in aerospace commonly include piezoelectric, capacitive, and resistive types, widely used for measuring parameters such as pressure, temperature, strain, and vibration. These conventional sensors rely on electrical signals, which can be susceptible to electromagnetic interference and signal degradation over long distances. In contrast, fiber optic sensors offer superior sensitivity, immunity to electromagnetic interference, and the ability to perform distributed sensing along the length of an optical fiber.

Key Differences Between Fiber Optic and Traditional Sensors

Fiber optic sensors use light to detect changes in temperature, pressure, or strain, offering immunity to electromagnetic interference and suitability for harsh environments, unlike traditional electrical sensors which rely on electrical signals and can be affected by electromagnetic noise. These sensors provide higher sensitivity and accuracy, enabling real-time monitoring in applications such as structural health monitoring, medical diagnostics, and industrial process control. Durability and miniaturization of fiber optic sensors also contribute to their preference over traditional sensors in remote or hazardous locations.

Performance Comparison: Accuracy and Reliability

Fiber optic sensors exhibit superior accuracy and reliability compared to traditional sensors due to their immunity to electromagnetic interference and ability to operate in harsh environments. Their high sensitivity enables precise measurements of parameters such as temperature, strain, and pressure with minimal signal degradation over long distances. Traditional sensors often suffer from signal loss and decreased performance in extreme conditions, making fiber optic sensors the preferred choice for critical applications requiring consistent measurement fidelity.

Environmental Suitability: Temperature, Vibration, and Radiation Resistance

Fiber optic sensors exhibit superior environmental suitability compared to traditional sensors, with high resistance to extreme temperatures ranging from -200degC to 700degC, making them ideal for harsh industrial applications. Their immunity to electromagnetic interference and vibration ensures accurate data capture in environments with significant mechanical stress, unlike conventional electronic sensors that can degrade under such conditions. Furthermore, fiber optic sensors withstand intense radiation levels, often found in nuclear and aerospace sectors, where traditional sensors fail due to radiation-induced signal degradation.

Weight and Space Considerations in Sensor Implementation

Fiber optic sensors offer significant advantages over traditional sensors in terms of weight and space efficiency, as their lightweight design reduces overall system mass and enables easier integration in compact environments. Their small size allows for deployment in tight or hard-to-reach areas where bulky traditional sensors would be impractical or impossible to install. These attributes make fiber optic sensors particularly valuable in aerospace, automotive, and medical applications where minimizing weight and optimizing space are critical for performance and safety.

Integration Complexity and Maintenance Requirements

Fiber optic sensors offer significantly lower integration complexity compared to traditional sensors due to their compact size, immunity to electromagnetic interference, and ease of embedding within various materials or structures. Maintenance requirements for fiber optic sensors are minimal because they have no moving parts and exhibit high durability against harsh environmental conditions, reducing downtime and calibration needs. In contrast, traditional sensors typically require more frequent maintenance and recalibration due to mechanical wear and susceptibility to environmental factors, increasing operational costs and complexity.

Cost Analysis and Lifecycle Management

Fiber optic sensors offer lower long-term maintenance costs and extended lifecycles compared to traditional sensors, due to their resistance to electromagnetic interference and harsh environments. Initial installation costs for fiber optic systems can be higher, but reduced downtime and minimal calibration requirements result in overall cost savings during the sensor lifecycle. Lifecycle management benefits also include easier integration with modern monitoring systems and superior durability, reducing replacement frequency and total cost of ownership.

Future Trends and Emerging Applications in Aerospace Sensing

Fiber optic sensors offer unparalleled benefits in aerospace sensing, including immunity to electromagnetic interference, lightweight construction, and high sensitivity, crucial for monitoring structural health and avionics systems. Emerging applications leverage distributed fiber optic sensing for real-time strain, temperature, and vibration measurements across aircraft wings and fuselage, enabling predictive maintenance and enhanced safety. Future trends emphasize integration with wireless networks and artificial intelligence to deliver smarter, more resilient aerospace sensing systems capable of adapting to extreme flight conditions.

Strain transfer efficiency

Fiber optic sensors offer significantly higher strain transfer efficiency compared to traditional sensors due to their superior sensitivity, immunity to electromagnetic interference, and ability to accurately detect minute strain variations over long distances.

Electromagnetic immunity

Fiber optic sensors provide superior electromagnetic immunity compared to traditional sensors, making them ideal for use in environments with high electromagnetic interference.

Multiplexing capability

Fiber optic sensors enable superior multiplexing capabilities by allowing multiple sensing points along a single fiber cable, unlike traditional sensors which typically require individual wiring for each sensor.

Distributed sensing

Fiber optic sensors enable highly precise distributed sensing along extensive lengths, surpassing traditional sensors by providing continuous, real-time data on temperature, strain, and pressure with minimal signal loss.

Weight reduction

Fiber optic sensors achieve significant weight reduction compared to traditional sensors by utilizing lightweight optical fibers instead of bulky metal components.

Remote sensing

Fiber optic sensors enable more accurate and reliable remote sensing over long distances compared to traditional sensors due to their immunity to electromagnetic interference, lightweight design, and high sensitivity to environmental changes.

Structural health monitoring

Fiber optic sensors provide higher sensitivity, immunity to electromagnetic interference, and real-time distributed monitoring capabilities, making them superior to traditional sensors for structural health monitoring of bridges, buildings, and infrastructure.

Signal attenuation

Fiber optic sensors exhibit significantly lower signal attenuation compared to traditional sensors, enabling longer transmission distances and enhanced signal integrity in industrial monitoring applications.

Environmental ruggedness

Fiber optic sensors offer superior environmental ruggedness compared to traditional sensors, with enhanced resistance to electromagnetic interference, extreme temperatures, moisture, and corrosive conditions.

Intrinsic safety

Fiber optic sensors offer intrinsic safety advantages over traditional sensors by eliminating electrical signals in hazardous environments, reducing ignition risks and enhancing operational security.

fibers optics sensors vs traditional sensors Infographic

njnir.com

njnir.com