Monocoque structures rely on the external skin to bear most of the load, resulting in a lightweight yet strong design ideal for streamlined aerospace applications. Semi-monocoque construction combines a load-bearing skin with an internal framework of ribs and stringers, enhancing durability and damage tolerance while maintaining high strength-to-weight ratios. This hybrid approach offers improved resistance to stress and deformation, making it the preferred choice for most modern aircraft fuselages.

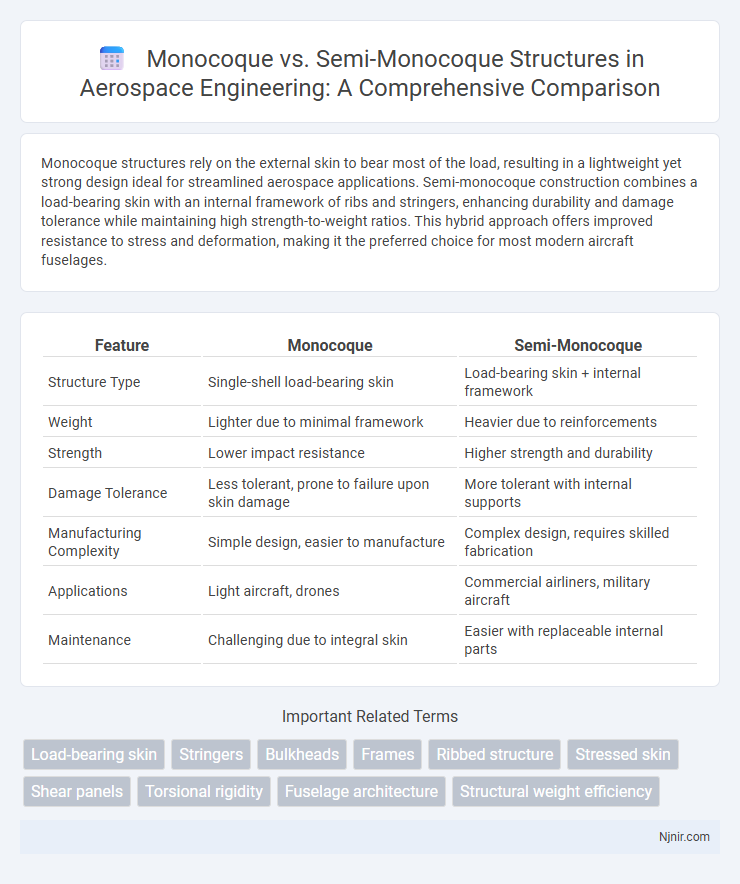

Table of Comparison

| Feature | Monocoque | Semi-Monocoque |

|---|---|---|

| Structure Type | Single-shell load-bearing skin | Load-bearing skin + internal framework |

| Weight | Lighter due to minimal framework | Heavier due to reinforcements |

| Strength | Lower impact resistance | Higher strength and durability |

| Damage Tolerance | Less tolerant, prone to failure upon skin damage | More tolerant with internal supports |

| Manufacturing Complexity | Simple design, easier to manufacture | Complex design, requires skilled fabrication |

| Applications | Light aircraft, drones | Commercial airliners, military aircraft |

| Maintenance | Challenging due to integral skin | Easier with replaceable internal parts |

Introduction to Aircraft Fuselage Structures

Monocoque aircraft fuselage structures derive their strength primarily from a stressed outer skin, eliminating the need for internal frames, which results in a lightweight design but can be less resistant to localized damage. Semi-monocoque fuselage structures combine a load-bearing skin with an internal framework of frames and stringers, providing enhanced durability, damage tolerance, and the ability to support higher stress loads. This structural approach is widely used in modern commercial and military aircraft due to its balance of strength, weight, and repairability.

Understanding Monocoque Construction

Monocoque construction uses the external skin to support structural loads, eliminating the need for an internal frame, which results in lightweight and fuel-efficient designs commonly used in modern aircraft and automotive industries. Semi-monocoque construction combines a load-bearing skin with an internal framework of ribs, stringers, and bulkheads, providing greater strength and damage tolerance while maintaining a relatively light structure. Understanding the balance between monocoque and semi-monocoque designs is crucial for optimizing structural integrity, weight, and performance in engineering applications.

Principles of Semi-Monocoque Design

Semi-monocoque design enhances structural integrity by combining a load-bearing skin with an internal framework of stringers and frames to distribute stress efficiently. This principle allows the aircraft fuselage to maintain strength while minimizing weight, optimizing aerodynamic performance and durability. Unlike pure monocoque, which relies solely on the skin for load support, semi-monocoque balances rigidity and flexibility through its reinforced sections.

Material Choices in Monocoque and Semi-Monocoque

Monocoque structures primarily utilize advanced composite materials such as carbon fiber and fiberglass to achieve high strength-to-weight ratios and enhanced rigidity. Semi-monocoque designs combine metal alloys like aluminum or titanium with composite reinforcements to optimize durability and impact resistance while maintaining relatively low weight. Material selection in both structures directly influences load distribution efficiency and overall performance in aerospace and automotive applications.

Load Distribution in Fuselage Structures

Monocoque fuselage structures distribute loads primarily through the external skin, relying on its strength and stiffness to maintain shape and handle aerodynamic forces. Semi-monocoque designs incorporate a combination of a load-bearing skin and an underlying framework of stringers and frames, which enhances structural integrity and improves load distribution by sharing stresses between components. This hybrid approach in semi-monocoque structures results in increased durability and damage tolerance compared to purely monocoque constructions.

Weight and Structural Efficiency Comparison

Monocoque structures feature a single shell that bears all loads, resulting in a lightweight design with high structural efficiency ideal for small aircraft and automotive applications. Semi-monocoque designs incorporate a load-bearing skin supported by an internal framework of frames and stringers, offering enhanced strength and damage tolerance at a slightly increased weight. The balance between minimal weight and structural resilience makes semi-monocoque the preferred choice for large commercial aircraft where safety and durability are critical.

Repair and Maintenance Considerations

Monocoque structures, composed of a single shell without internal framework, often require specialized techniques for repair due to their continuous load-bearing skin, making damage assessment and patching more complex compared to semi-monocoque designs. Semi-monocoque fuselages feature a combination of a load-bearing skin reinforced by an internal framework of stringers and frames, allowing easier access for inspections and localized repairs without compromising overall integrity. Maintenance operations in semi-monocoque aircraft are generally more straightforward, enhancing serviceability and reducing downtime through modular replacements and targeted structural assessments.

Application Examples in Modern Aerospace Engineering

Monocoque structures are commonly applied in lightweight UAVs and gliders, where the outer shell bears most of the load, offering weight savings and aerodynamic efficiency. Semi-monocoque designs dominate commercial airliners and military fighter jets, combining a stressed skin with internal frames and stringers to provide superior strength and damage tolerance. This hybrid approach in semi-monocoque aircraft facilitates maintenance and enhances structural resilience under dynamic flight stresses.

Advantages and Limitations of Each Structure

Monocoque structures offer superior strength-to-weight ratios by distributing stress across the entire skin, resulting in lightweight and highly aerodynamic designs ideal for modern aircraft. However, monocoque frames can be more susceptible to localized damage, leading to potential structural failure if the skin is compromised. Semi-monocoque designs combine a load-bearing skin with internal frames and stringers, enhancing damage tolerance and ease of repair, but this added complexity often results in increased weight and manufacturing costs.

Future Trends in Aircraft Structural Design

Future trends in aircraft structural design emphasize the evolution from traditional monocoque to advanced semi-monocoque structures, enhancing durability and weight efficiency by combining stressed skin with internal frameworks. Innovations in composite materials and additive manufacturing enable semi-monocoque designs to achieve superior strength-to-weight ratios, improving fuel efficiency and reducing environmental impact. Emerging smart structures with embedded sensors in semi-monocoque frameworks facilitate real-time health monitoring and adaptive load management, driving the next generation of aerospace engineering.

Load-bearing skin

Monocoque structures rely entirely on load-bearing skin to support stresses, whereas semi-monocoque designs combine load-bearing skin with internal frames or stringers for enhanced strength and durability.

Stringers

Stringers in monocoque structures primarily support tensile loads by reinforcing the skin, whereas in semi-monocoque designs, stringers distribute stress between the skin and internal frames, enhancing overall structural rigidity.

Bulkheads

Bulkheads in monocoque structures serve as integral load-bearing components, while in semi-monocoque designs, bulkheads provide additional reinforcement and support to the primary outer skin and frame.

Frames

Monocoque frames integrate the structure and skin into a single load-bearing shell, offering lightweight strength, while semi-monocoque frames combine a skeletal frame with additional skin support to enhance durability and impact resistance.

Ribbed structure

Monocoque structures rely solely on their ribbed shell for strength and load distribution, whereas semi-monocoque designs integrate a ribbed framework with a supportive internal skeleton for enhanced durability and weight efficiency.

Stressed skin

Monocoque structures rely entirely on stressed skin to bear loads, whereas semi-monocoque designs combine stressed skin with internal frames for enhanced strength and rigidity.

Shear panels

Shear panels in monocoque structures carry all the load through the external skin, while in semi-monocoque designs, the shear panels work with internal frames and stringers to distribute stresses more efficiently.

Torsional rigidity

Monocoque structures offer higher torsional rigidity due to their integral load-bearing skin, whereas semi-monocoque designs balance torsional strength with added internal reinforcements for improved durability.

Fuselage architecture

Monocoque fuselage architecture relies on a single shell structure to bear loads, while semi-monocoque combines a load-bearing skin with internal frames and stringers for increased strength and damage tolerance.

Structural weight efficiency

Monocoque structures offer higher structural weight efficiency by integrating the skin and frame into a single load-bearing shell, whereas semi-monocoque designs balance weight and strength by combining a load-bearing skin with internal supports.

monocoque vs semi-monocoque Infographic

njnir.com

njnir.com