Hybrid rockets combine solid fuel with a liquid oxidizer, offering simpler design and enhanced safety compared to fully liquid rockets. Liquid rockets provide higher performance and greater thrust control, making them ideal for complex mission profiles. Engineers must weigh the trade-offs between the reliability of hybrids and the efficiency of liquid propulsion systems when selecting the optimal rocket type.

Table of Comparison

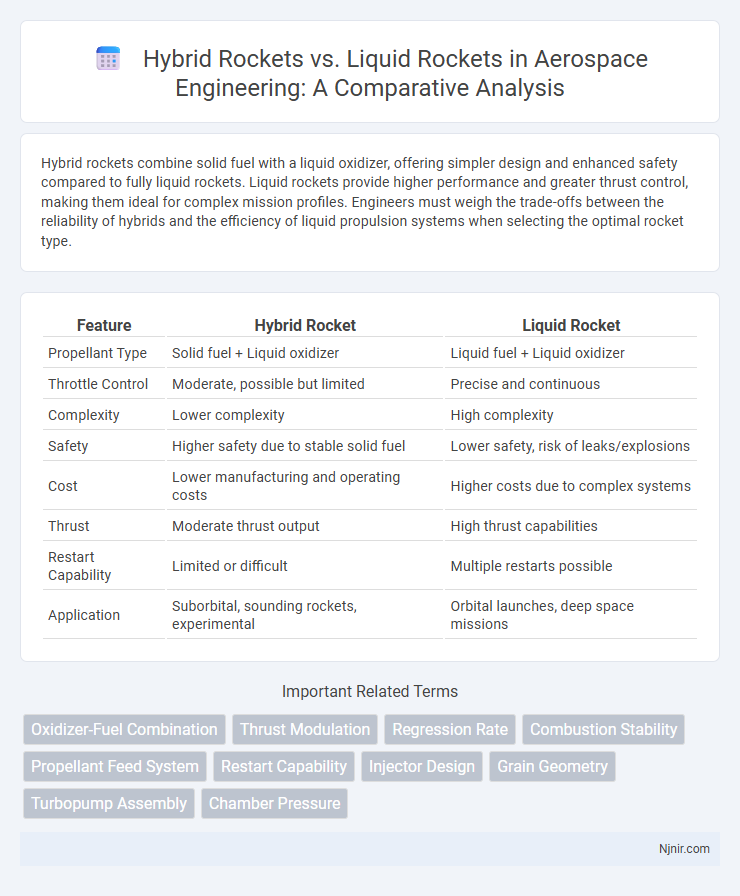

| Feature | Hybrid Rocket | Liquid Rocket |

|---|---|---|

| Propellant Type | Solid fuel + Liquid oxidizer | Liquid fuel + Liquid oxidizer |

| Throttle Control | Moderate, possible but limited | Precise and continuous |

| Complexity | Lower complexity | High complexity |

| Safety | Higher safety due to stable solid fuel | Lower safety, risk of leaks/explosions |

| Cost | Lower manufacturing and operating costs | Higher costs due to complex systems |

| Thrust | Moderate thrust output | High thrust capabilities |

| Restart Capability | Limited or difficult | Multiple restarts possible |

| Application | Suborbital, sounding rockets, experimental | Orbital launches, deep space missions |

Introduction to Rocket Propulsion Systems

Hybrid rockets combine solid fuel with liquid oxidizers, offering a balance between simplicity and controllability in propulsion systems. Liquid rockets utilize liquid propellants stored in separate tanks, delivering high efficiency and precise thrust control through complex engine designs. Both systems play crucial roles in aerospace applications, with hybrids often favored for safety and cost-effectiveness, while liquids excel in performance and mission versatility.

Fundamental Principles of Hybrid Rockets

Hybrid rockets combine a solid fuel with a liquid or gaseous oxidizer, enabling controlled combustion through the precise regulation of the oxidizer flow. The fundamental principle relies on the separation of fuel and oxidizer phases, offering safety advantages and throttle control compared to fully solid or liquid rockets. This design allows for simpler engine architecture, reduced combustion instability, and improved performance flexibility in hybrid propulsion systems.

Fundamental Principles of Liquid Rockets

Liquid rockets operate by combusting liquid propellants, typically a fuel like liquid hydrogen and an oxidizer such as liquid oxygen, within a combustion chamber to generate high-pressure and high-temperature gases that are expelled through a nozzle to produce thrust. The precise control of propellant flow rates using turbopumps enables variable thrust and efficient combustion, enhancing performance compared to hybrid rockets that combine solid fuel with liquid oxidizers. Liquid propulsion systems rely on complex plumbing, cooling mechanisms, and ignition systems to sustain combustion and maximize engine efficiency, distinguishing them from the simpler design of hybrid rockets.

Performance Comparison: Thrust and Efficiency

Hybrid rockets offer moderate thrust levels between solid and liquid rockets, leveraging a combination of solid fuel and liquid oxidizer to enhance control and safety. Liquid rockets provide superior thrust and higher specific impulse due to precise combustion of liquid propellants, resulting in greater efficiency for complex missions. Thrust performance in liquid rockets typically ranges from 200 kN to over 1,000 kN with specific impulses up to 450 seconds, while hybrid rockets usually achieve thrusts under 500 kN and specific impulses around 300 seconds.

Propellant Types and Storage Requirements

Hybrid rockets use a combination of solid fuel and liquid oxidizer, offering simpler storage requirements since the solid fuel is stable and the liquid oxidizer can be stored at moderate pressures. Liquid rockets utilize both liquid fuel and liquid oxidizer, necessitating complex storage solutions with cryogenic or hypergolic propellants requiring insulated tanks and pressurization systems. The hybrid system's use of less volatile solid fuels reduces handling risks compared to the fully liquid propellant systems that demand precise temperature control and safety measures for both components.

Safety Considerations in Hybrid vs Liquid Rockets

Hybrid rockets offer enhanced safety compared to liquid rockets due to the separation of solid fuel and liquid oxidizer, minimizing the risk of explosive combustion. Liquid rockets involve handling highly volatile propellants stored under high pressure, increasing the potential for leaks and catastrophic failures during fueling, launch, or storage. The simpler design and inert nature of hybrid fuel components reduce ignition hazards and enable safer shutdown and restart procedures, making hybrids favorable in applications where operational safety is critical.

Cost Analysis: Development and Operation

Hybrid rockets typically offer lower development costs due to simpler fuel handling and fewer complex components compared to liquid rockets, which require intricate plumbing and cryogenic systems. Operating expenses for hybrid rockets are generally more affordable because their solid-fuel components reduce the need for expensive propellant storage and fueling infrastructure found in liquid propulsion systems. Liquid rockets, despite higher upfront and operational costs, provide better performance control and efficiency, often justifying investment in high-budget space missions.

Environmental Impact Assessment

Hybrid rockets often have a lower environmental impact than liquid rockets due to their simpler design and use of less toxic propellants, which reduces hazardous emissions during operation. Liquid rockets typically rely on highly reactive or toxic fuels such as hydrazine, producing more harmful byproducts and increasing the complexity of handling and disposal. The environmental impact assessment favors hybrid systems for cleaner combustion, reduced ground contamination, and potentially lower carbon footprints in space launch applications.

Applications in Aerospace Missions

Hybrid rockets provide a balance of safety and throttle control, making them ideal for suborbital and research missions where cost efficiency and restart capability are critical. Liquid rockets dominate in orbital launches and deep space exploration due to their high specific impulse, precise thrust modulation, and ability to support multi-stage configurations. The aerospace industry leverages hybrids for experimental payload delivery and reusable vehicle testing, while liquid propulsion systems are preferred for heavy-lift launch vehicles and interplanetary missions.

Future Trends and Technological Advancements

Hybrid rockets offer a blend of solid and liquid propulsion benefits, enhancing safety and throttle control, which positions them as a promising choice for future space missions. Liquid rockets, with advanced cryogenic and electric pump-fed engines, continue to push efficiency and reusability boundaries, essential for long-duration and deep-space exploration. Emerging trends include additive manufacturing for complex engine components and AI-driven control systems, accelerating hybrid and liquid rocket innovation in the coming decades.

Oxidizer-Fuel Combination

Hybrid rockets utilize a liquid oxidizer paired with a solid fuel, offering simplified engine design and throttling capabilities, while liquid rockets combine both liquid oxidizers and liquid fuels for higher performance and precise control.

Thrust Modulation

Hybrid rockets enable precise thrust modulation by controlling oxidizer flow, whereas liquid rockets achieve thrust modulation through variable propellant mixture ratios and pump speeds.

Regression Rate

Hybrid rockets exhibit lower regression rates due to solid fuel grain limitations, while liquid rockets achieve higher thrust control with variable propellant flow.

Combustion Stability

Hybrid rockets offer improved combustion stability due to the separation of solid fuel and liquid oxidizer, reducing combustion oscillations commonly found in liquid rockets.

Propellant Feed System

Hybrid rockets use a simpler, pressure-fed propellant system combining solid fuel and liquid oxidizer, whereas liquid rockets employ complex turbopump-driven feed systems for both liquid fuel and oxidizer delivery.

Restart Capability

Hybrid rockets offer limited mid-flight restart capability compared to liquid rockets, which provide reliable multiple engine restarts for mission flexibility and precise orbital insertion.

Injector Design

Hybrid rocket injectors combine solid and liquid propellant flow systems, offering simpler design and throttling control compared to the complex multi-element injectors required for precise mixing in liquid rockets.

Grain Geometry

Hybrid rockets utilize variable grain geometry to optimize combustion efficiency and thrust profiles, whereas liquid rockets rely on precise injector design for propellant flow control.

Turbopump Assembly

Hybrid rockets generally use simpler, lower-pressure turbopump assemblies compared to the complex, high-pressure turbopumps required for liquid rockets, resulting in reduced weight and cost but lower performance efficiency.

Chamber Pressure

Hybrid rockets typically operate at lower chamber pressures around 10-15 MPa compared to liquid rockets, which achieve higher chamber pressures exceeding 20 MPa, resulting in greater thrust efficiency and performance.

Hybrid Rocket vs Liquid Rocket Infographic

njnir.com

njnir.com