Ionic wind propulsion offers a quieter and more efficient alternative to traditional ducted fan propulsion by generating thrust through ionized air molecules without moving parts. This technology reduces mechanical wear and enhances aerodynamic performance in aerospace applications, making it ideal for precise control and low-noise environments. Although ionic wind systems currently produce lower thrust levels compared to ducted fans, ongoing advancements promise increased power and scalability for future aerospace vehicles.

Table of Comparison

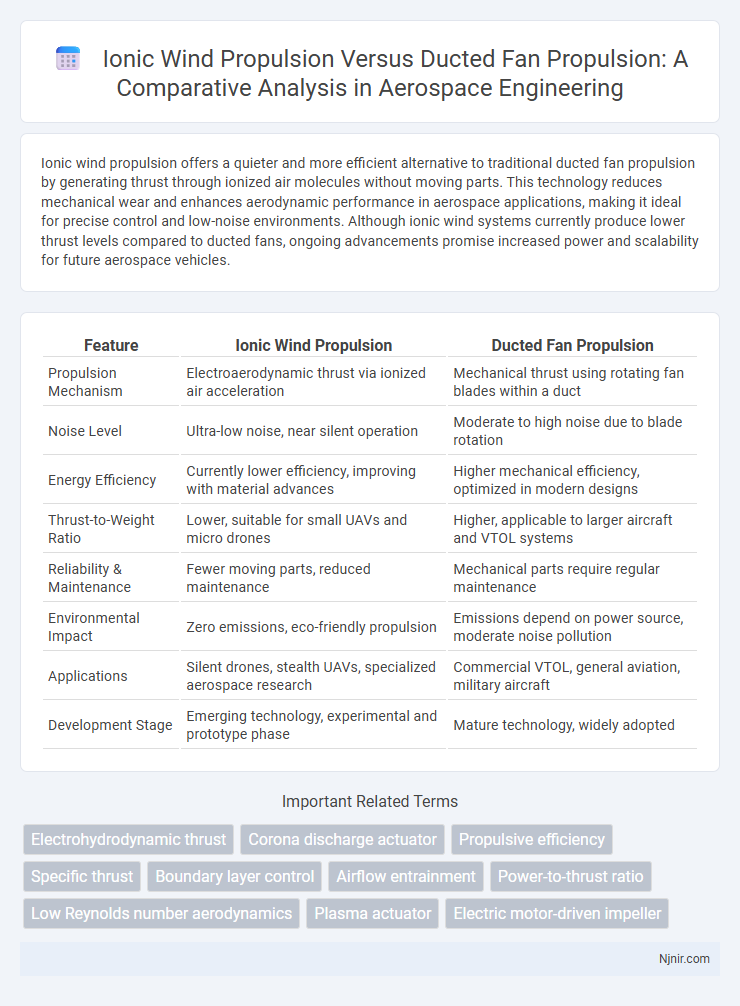

| Feature | Ionic Wind Propulsion | Ducted Fan Propulsion |

|---|---|---|

| Propulsion Mechanism | Electroaerodynamic thrust via ionized air acceleration | Mechanical thrust using rotating fan blades within a duct |

| Noise Level | Ultra-low noise, near silent operation | Moderate to high noise due to blade rotation |

| Energy Efficiency | Currently lower efficiency, improving with material advances | Higher mechanical efficiency, optimized in modern designs |

| Thrust-to-Weight Ratio | Lower, suitable for small UAVs and micro drones | Higher, applicable to larger aircraft and VTOL systems |

| Reliability & Maintenance | Fewer moving parts, reduced maintenance | Mechanical parts require regular maintenance |

| Environmental Impact | Zero emissions, eco-friendly propulsion | Emissions depend on power source, moderate noise pollution |

| Applications | Silent drones, stealth UAVs, specialized aerospace research | Commercial VTOL, general aviation, military aircraft |

| Development Stage | Emerging technology, experimental and prototype phase | Mature technology, widely adopted |

Introduction to Advanced Propulsion Systems in Aerospace

Ionic wind propulsion offers a silent, efficient thrust generation mechanism using electroaerodynamic forces without moving parts, contrasting with ducted fan propulsion which relies on mechanical blades enclosed within a shroud to enhance thrust and reduce noise. Both systems present unique advantages for advanced aerospace applications, where ionic wind systems promise reduced mechanical complexity and enhanced control, while ducted fans deliver higher thrust density critical for larger aircraft. Emerging research focuses on integrating ionic propulsion for small UAVs and drones, leveraging its low noise and maintenance-free operation, whereas ducted fans continue to dominate in commercial and military aircraft requiring robust thrust output and aerodynamic efficiency.

Fundamentals of Ionic Wind Propulsion

Ionic wind propulsion generates thrust by ionizing air molecules that are accelerated through an electric field, producing a flow of charged particles without moving mechanical parts. This method differs fundamentally from ducted fan propulsion, which relies on rotating blades to displace air and create thrust. The key advantage of ionic wind lies in its silent operation, zero mechanical wear, and potential for high efficiency in low-speed applications.

Working Principles of Ducted Fan Propulsion

Ducted fan propulsion operates by enclosing a multi-blade fan within a cylindrical shroud or duct, enhancing thrust efficiency and noise reduction by controlling airflow and minimizing tip vortices. The duct accelerates air through the fan blades driven by an electric or combustion engine, creating a high-velocity jet stream that generates thrust. This configuration improves aerodynamic performance and propulsive efficiency compared to open rotor designs, making it effective for applications in drones, electric vertical takeoff and landing (eVTOL) aircraft, and marine vessels.

Comparative Efficiency: Ionic Wind vs Ducted Fan

Ionic wind propulsion generates thrust by ionizing air and accelerating ions through electric fields, resulting in low mechanical noise and no moving parts but typically lower thrust efficiency compared to ducted fans. Ducted fan propulsion utilizes rotating blades enclosed within a shroud to increase airflow and thrust, offering higher thrust-to-power ratios and improved aerodynamic efficiency under a wide range of operating conditions. While ionic wind excels in silent and compact applications, ducted fans outperform in energy efficiency and thrust output, making them more suitable for high-demand propulsion systems.

Power Consumption and Energy Sources

Ionic Wind Propulsion consumes significantly less power than ducted fan propulsion due to its lack of moving mechanical parts, relying instead on electrohydrodynamic forces generated by high-voltage electric fields. Energy sources for ionic wind systems are typically high-voltage power supplies powered by batteries or renewable energy, making them suitable for lightweight, energy-efficient applications. In contrast, ducted fan propulsion demands higher power input from electric motors or fuel-based engines, resulting in greater energy consumption and a heavier power source to sustain operation.

Noise Levels and Environmental Impact

Ionic wind propulsion generates thrust by ionizing air molecules, resulting in virtually silent operation with negligible mechanical noise, significantly reducing noise pollution compared to ducted fan propulsion, which relies on high-speed rotating blades producing considerable aerodynamic noise. Environmentally, ionic wind systems produce zero direct emissions and operate without combustion, offering a cleaner alternative to ducted fans that often require high energy input and may contribute to higher greenhouse gas emissions depending on the power source. The ion propulsion's minimal moving parts also reduce maintenance waste, enhancing its sustainability advantage over traditional ducted fan systems.

Design Constraints and Scalability

Ionic wind propulsion faces significant design constraints due to low thrust-to-weight ratios and high voltage requirements, limiting its scalability for larger aircraft. Ducted fan propulsion benefits from established aerodynamic principles and higher thrust efficiency, allowing easier scaling for varying aircraft sizes. Material limitations and power supply efficiency remain critical challenges in optimizing both propulsion types for practical, scalable aerospace applications.

Flight Performance and Applications

Ionic wind propulsion offers silent thrust with no moving parts, resulting in high efficiency for small-scale, low-speed applications such as micro aerial vehicles and drones. In contrast, ducted fan propulsion provides greater thrust and better aerodynamic efficiency, enabling faster speeds and heavier payload capacities, making it suitable for commercial and military aircraft. Flight performance of ionic wind systems remains limited by current power density constraints, whereas ducted fans excel in applications requiring robust and sustained high-output propulsion.

Recent Innovations and Research Trends

Recent innovations in Ionic Wind Propulsion emphasize enhanced thrust-to-weight ratios through novel electrode materials and optimized corona discharge configurations, enabling quieter, vibration-free flight. Research in ducted fan propulsion focuses on advanced composite materials and adaptive blade designs to improve aerodynamic efficiency and noise reduction in urban air mobility applications. Comparative studies highlight Ionic Wind's potential for low-speed, low-noise UAVs, while ducted fans dominate high-thrust, versatile propulsion systems in commercial drones and eVTOL aircraft.

Future Prospects in Aerospace Mobility

Ionic wind propulsion offers the potential for ultra-quiet, low-emission aerospace vehicles by eliminating moving parts and reducing mechanical complexity, making it ideal for urban air mobility and short-range drones. Ducted fan propulsion provides higher thrust efficiency and scalability for larger aircraft, supporting advancements in electric vertical takeoff and landing (eVTOL) vehicles and regional air transport. Future aerospace mobility could see hybrid integration of ionic wind systems for noise-sensitive environments and ducted fans for improved performance and payload capacity.

Electrohydrodynamic thrust

Electrohydrodynamic thrust in Ionic Wind Propulsion generates silent, solid-state airflow without moving parts, offering higher efficiency and reduced mechanical wear compared to the mechanically driven, noise-producing Ducted Fan Propulsion systems.

Corona discharge actuator

Corona discharge actuators in Ionic Wind Propulsion generate thrust through ionized air movement without moving parts, offering quieter operation and reduced mechanical complexity compared to the high-thrust, mechanically driven airflow produced by Ducted Fan Propulsion systems.

Propulsive efficiency

Ionic wind propulsion achieves lower propulsive efficiency compared to ducted fan propulsion due to limited thrust-to-power ratio and higher energy losses in ion generation processes.

Specific thrust

Ionic wind propulsion generates lower specific thrust compared to ducted fan propulsion due to its reliance on ionized air acceleration, resulting in higher efficiency at low speeds but limited thrust output for heavier applications.

Boundary layer control

Ionic wind propulsion minimizes boundary layer separation by generating a steady, high-velocity ion wind over surfaces, while ducted fan propulsion enhances boundary layer control through increased airflow momentum and reduced turbulence within the duct.

Airflow entrainment

Ionic wind propulsion produces slower, highly ionized airflow with low entrainment efficiency, whereas ducted fan propulsion generates faster, mechanically-driven airflow with significantly higher entrainment and thrust efficiency.

Power-to-thrust ratio

Ionic wind propulsion achieves a higher power-to-thrust ratio than ducted fan propulsion by generating thrust through electrostatic ion acceleration without moving parts, resulting in greater efficiency and reduced mechanical losses.

Low Reynolds number aerodynamics

Ionic wind propulsion offers efficient thrust generation with minimal mechanical parts at low Reynolds numbers, while ducted fan propulsion provides higher thrust density but experiences increased aerodynamic losses due to viscous effects in low Reynolds number regimes.

Plasma actuator

Plasma actuators in Ionic Wind Propulsion generate ionized airflow without moving parts, offering higher efficiency and lower noise compared to the mechanical complexity and aerodynamic drag of Ducted Fan Propulsion systems.

Electric motor-driven impeller

Electric motor-driven impellers in ionic wind propulsion generate thrust through ionized air acceleration without moving parts, offering silent, low-maintenance operation compared to the mechanically complex, high-thrust ducted fan propulsion systems.

Ionic Wind Propulsion vs Ducted Fan Propulsion Infographic

njnir.com

njnir.com