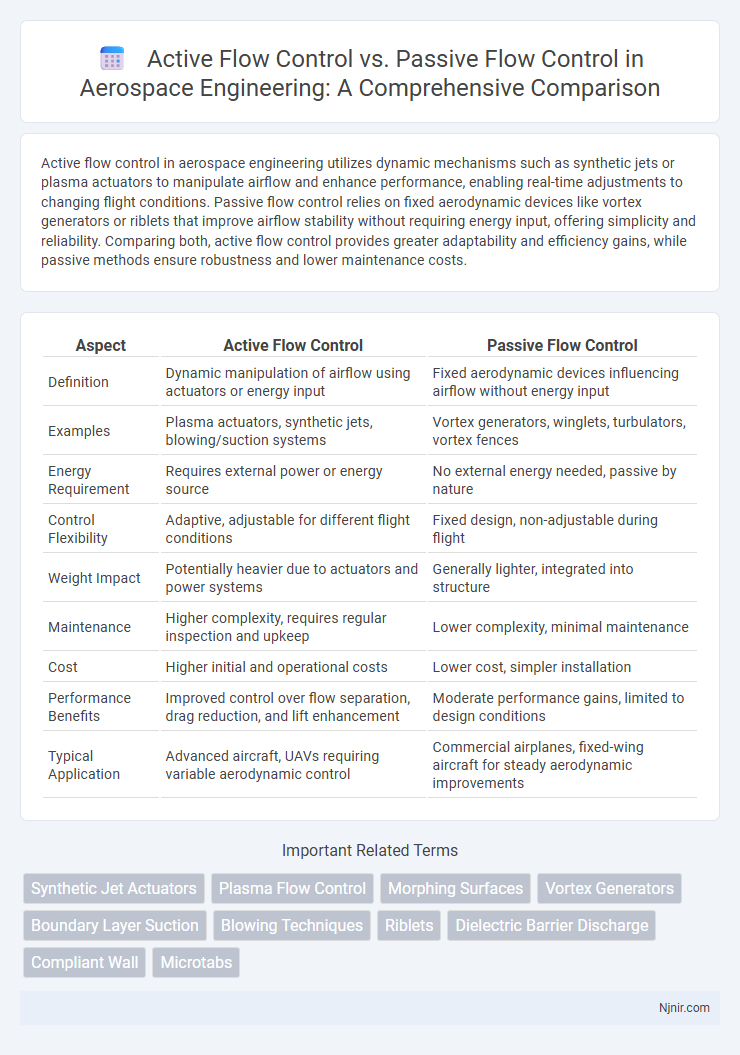

Active flow control in aerospace engineering utilizes dynamic mechanisms such as synthetic jets or plasma actuators to manipulate airflow and enhance performance, enabling real-time adjustments to changing flight conditions. Passive flow control relies on fixed aerodynamic devices like vortex generators or riblets that improve airflow stability without requiring energy input, offering simplicity and reliability. Comparing both, active flow control provides greater adaptability and efficiency gains, while passive methods ensure robustness and lower maintenance costs.

Table of Comparison

| Aspect | Active Flow Control | Passive Flow Control |

|---|---|---|

| Definition | Dynamic manipulation of airflow using actuators or energy input | Fixed aerodynamic devices influencing airflow without energy input |

| Examples | Plasma actuators, synthetic jets, blowing/suction systems | Vortex generators, winglets, turbulators, vortex fences |

| Energy Requirement | Requires external power or energy source | No external energy needed, passive by nature |

| Control Flexibility | Adaptive, adjustable for different flight conditions | Fixed design, non-adjustable during flight |

| Weight Impact | Potentially heavier due to actuators and power systems | Generally lighter, integrated into structure |

| Maintenance | Higher complexity, requires regular inspection and upkeep | Lower complexity, minimal maintenance |

| Cost | Higher initial and operational costs | Lower cost, simpler installation |

| Performance Benefits | Improved control over flow separation, drag reduction, and lift enhancement | Moderate performance gains, limited to design conditions |

| Typical Application | Advanced aircraft, UAVs requiring variable aerodynamic control | Commercial airplanes, fixed-wing aircraft for steady aerodynamic improvements |

Introduction to Flow Control in Aerospace Engineering

Active flow control in aerospace engineering involves the use of energy input, such as synthetic jets or plasma actuators, to manipulate airflow over aircraft surfaces for enhanced performance and reduced drag. Passive flow control relies on fixed geometric features like vortex generators or surface roughness to alter airflow without external energy, offering simplicity and reliability. Understanding the distinctions between active and passive flow control is critical for designing aerodynamic systems that optimize lift, control flow separation, and improve fuel efficiency in modern aircraft.

Fundamentals of Active Flow Control

Active Flow Control involves dynamically manipulating fluid flows using energy inputs like actuators or synthetic jets to enhance aerodynamic performance, reduce drag, or delay flow separation. It relies on real-time adjustments to alter boundary layer behavior, increasing control authority over flow structures compared to Passive Flow Control, which uses fixed devices like vortex generators or riblets without energy input. Fundamentals of Active Flow Control include understanding flow instability mechanisms, actuator placement, feedback systems, and energy efficiency to optimize flow manipulation and improve overall system effectiveness in applications such as aircraft wings, turbines, and automotive aerodynamics.

Principles of Passive Flow Control

Passive flow control relies on fixed aerodynamic features such as vortex generators, riblets, or winglets to manipulate airflow without external energy input, enhancing lift and reducing drag through the stabilization of boundary layers. These devices exploit natural fluid dynamics principles like delaying flow separation and minimizing turbulence by altering surface geometry. The simplicity and reliability of passive flow control make it widely applicable in aerospace and automotive industries, offering continuous aerodynamic benefits with minimal maintenance.

Key Technologies in Active Flow Control

Active Flow Control technologies harness energy input to manipulate airflow dynamically, enhancing lift, reducing drag, and delaying flow separation through methods such as synthetic jet actuators, plasma actuators, and oscillating flaps. Synthetic jet actuators create controlled vortices by vibrating diaphragms to inject momentum into the boundary layer, while plasma actuators generate ionized air for non-mechanical flow modification, offering rapid response with minimal mechanical complexity. Oscillating flaps induce periodic disturbances that energize the boundary layer, enabling precise control over flow structures compared to passive flow control devices, which rely on fixed geometries and do not require external energy input.

Typical Passive Flow Control Devices

Typical passive flow control devices include vortex generators, riblets, and surface roughness elements designed to alter flow behavior without energy input. These devices manipulate boundary layer characteristics to reduce drag, delay flow separation, or enhance mixing by maintaining stable flow patterns. Their effectiveness depends on geometric configuration and placement, offering a reliable, low-maintenance solution compared to active flow control systems.

Performance Comparison: Active vs Passive

Active flow control systems leverage real-time adjustments to manipulate fluid dynamics, resulting in enhanced performance metrics such as increased lift, reduced drag, and improved fuel efficiency compared to passive flow control methods. Passive flow control relies on fixed devices like vortex generators or riblets that provide consistent but less adaptable aerodynamic benefits, often leading to lower overall effectiveness in varying operational conditions. Studies demonstrate that active flow control can achieve up to 20% more drag reduction and lift enhancement, significantly outperforming passive techniques in dynamic environments.

Energy Consumption and Efficiency

Active flow control systems utilize energy-consuming devices like actuators or synthetic jets to manipulate fluid dynamics, resulting in higher energy consumption but improved aerodynamic efficiency and control. Passive flow control relies on fixed geometric modifications such as vortex generators or turbulators, which consume no external energy and offer moderate improvements in flow stability and drag reduction. Energy efficiency favors passive methods due to zero power input, while active control achieves superior performance metrics at the cost of increased operational energy expenditure.

Applications in Aircraft Design

Active flow control in aircraft design utilizes dynamic devices like synthetic jets and plasma actuators to manipulate airflow, enhancing lift, reducing drag, and improving maneuverability during various flight phases. Passive flow control relies on fixed structures such as vortex generators, turbulators, and vortex fences to delay flow separation and maintain stable aerodynamic performance without external energy input. Active methods offer adaptability for performance optimization in different flight conditions, while passive techniques provide reliable and low-maintenance solutions for steady-state efficiency.

Challenges and Limitations

Active flow control faces challenges such as high energy consumption, complex system integration, and sensitivity to operational conditions, limiting its practical deployment in aerodynamic applications. Passive flow control, while more reliable and energy-efficient, struggles with adaptability to varying flow regimes and often provides less precise control over turbulence and separation. Both methods require careful consideration of trade-offs between effectiveness, implementation complexity, and operational environments to optimize performance in aerospace and automotive engineering.

Future Trends in Flow Control Systems

Future trends in flow control systems emphasize increased integration of active flow control technologies, leveraging real-time sensing and adaptive algorithms to optimize aerodynamic performance and energy efficiency. Passive flow control methods continue evolving with advanced materials and surface textures that reduce drag and delay flow separation without external energy input. The convergence of smart sensors, machine learning, and energy-efficient actuation promises more responsive and sustainable solutions in aerospace, automotive, and industrial applications.

Synthetic Jet Actuators

Synthetic jet actuators in active flow control generate controlled oscillatory jets without net mass injection, providing dynamic boundary layer manipulation superior to passive flow control's fixed geometry devices for enhancing aerodynamic performance.

Plasma Flow Control

Plasma flow control, an active flow control technique using ionized gas to manipulate aerodynamic surfaces, offers precise, energy-efficient performance improvements over traditional passive flow control methods like vortex generators and turbulators.

Morphing Surfaces

Morphing surfaces in active flow control dynamically adapt shape to optimize aerodynamics, offering superior performance and efficiency compared to fixed-geometry passive flow control methods.

Vortex Generators

Active flow control using adjustable vortex generators dynamically enhances boundary layer separation delay, whereas passive vortex generators rely on fixed structures to induce vortices for improved aerodynamic performance.

Boundary Layer Suction

Boundary layer suction in active flow control effectively reduces drag and delays flow separation by actively removing low-momentum fluid, contrasting with passive flow control methods that rely on static surface modifications.

Blowing Techniques

Blowing techniques in active flow control precisely manipulate airflow by injecting momentum through controlled jets, unlike passive flow control which relies on fixed geometric modifications to alter the flow behavior.

Riblets

Riblets, a passive flow control technique inspired by shark skin, reduce drag by minimizing turbulent vortices on surfaces without external energy input, whereas active flow control methods dynamically manipulate airflow using actuators or synthetic jets to achieve similar drag reduction but with higher energy consumption.

Dielectric Barrier Discharge

Dielectric Barrier Discharge (DBD) enables active flow control by generating plasma-induced momentum to manipulate airflow dynamically, offering superior adaptability compared to passive flow control methods that rely on fixed physical structures.

Compliant Wall

Compliant walls in active flow control dynamically adapt surface characteristics to reduce drag and suppress turbulence, offering more efficient and controllable aerodynamic performance compared to passive flow control methods.

Microtabs

Microtabs in active flow control dynamically modify airflow to reduce drag and delay separation, offering superior adaptability compared to fixed passive flow control devices.

Active Flow Control vs Passive Flow Control Infographic

njnir.com

njnir.com