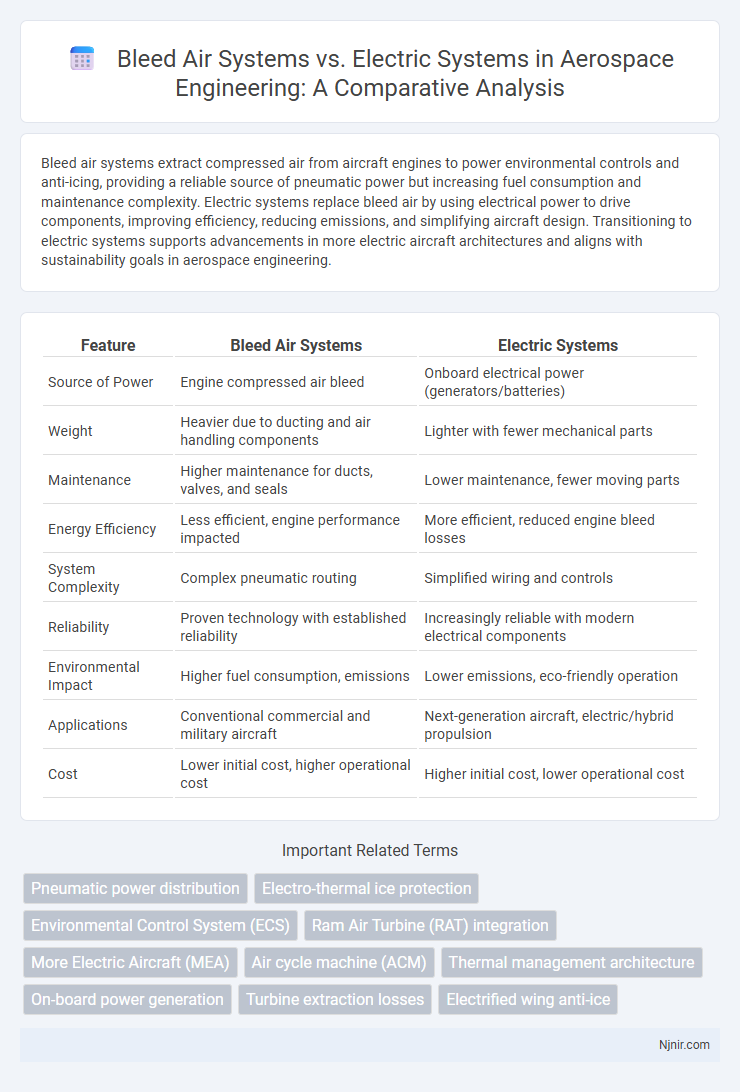

Bleed air systems extract compressed air from aircraft engines to power environmental controls and anti-icing, providing a reliable source of pneumatic power but increasing fuel consumption and maintenance complexity. Electric systems replace bleed air by using electrical power to drive components, improving efficiency, reducing emissions, and simplifying aircraft design. Transitioning to electric systems supports advancements in more electric aircraft architectures and aligns with sustainability goals in aerospace engineering.

Table of Comparison

| Feature | Bleed Air Systems | Electric Systems |

|---|---|---|

| Source of Power | Engine compressed air bleed | Onboard electrical power (generators/batteries) |

| Weight | Heavier due to ducting and air handling components | Lighter with fewer mechanical parts |

| Maintenance | Higher maintenance for ducts, valves, and seals | Lower maintenance, fewer moving parts |

| Energy Efficiency | Less efficient, engine performance impacted | More efficient, reduced engine bleed losses |

| System Complexity | Complex pneumatic routing | Simplified wiring and controls |

| Reliability | Proven technology with established reliability | Increasingly reliable with modern electrical components |

| Environmental Impact | Higher fuel consumption, emissions | Lower emissions, eco-friendly operation |

| Applications | Conventional commercial and military aircraft | Next-generation aircraft, electric/hybrid propulsion |

| Cost | Lower initial cost, higher operational cost | Higher initial cost, lower operational cost |

Introduction to Bleed Air and Electric Systems

Bleed air systems extract high-pressure air from the engine compressor to supply pneumatic power for aircraft functions such as cabin pressurization, anti-icing, and environmental control. Electric systems utilize electrical power generated by the engine-driven generators and batteries to operate systems like avionics, lighting, and electrically driven actuators. Comparing these, bleed air systems rely on pneumatic energy conversion, while electric systems emphasize energy efficiency and reduced maintenance by eliminating air-driven components.

Historical Development in Aerospace Applications

Bleed air systems emerged in early aerospace designs due to their simplicity and reliability for cabin pressurization and environmental control, utilizing compressed air bled from engine compressors. Electric systems have progressively gained prominence since the late 20th century, driven by advancements in electrical power generation and distribution, offering improved efficiency and reduced maintenance compared to traditional bleed air setups. The transition reflects the aerospace industry's shift toward More-Electric Aircraft (MEA) concepts, aiming for enhanced performance and lower operating costs.

Fundamental Principles of Bleed Air Systems

Bleed air systems operate by extracting high-pressure, high-temperature air from the compressor stage of a jet engine, which is then cooled and conditioned for various aircraft functions such as cabin pressurization and anti-icing. These systems rely on pneumatic principles, utilizing pressurized air flow to transfer energy and perform work without the need for electrical components. Unlike electric systems that depend on generators and motors, bleed air systems leverage the engine's inherent airflow dynamics, making them fundamental in traditional aircraft environmental control and power distribution.

Foundational Concepts of Electric Systems

Electric systems rely on electrical power generated by the aircraft's engines or auxiliary power units, providing energy for critical functions such as avionics, lighting, and environmental controls without tapping into engine bleed air. Unlike bleed air systems that divert compressed air from engine compressors, electric systems offer enhanced efficiency, reduced maintenance, and improved environmental performance by minimizing fuel consumption and emissions. Fundamental to modern aircraft design, electric systems enable precise control and integration of various subsystems, supporting the evolution toward more electric and hybrid-electric aircraft architectures.

Comparative Analysis: Efficiency and Performance

Bleed air systems draw high-pressure air from the engine compressor to power aircraft systems, offering simplicity but reduced overall fuel efficiency due to energy losses in air extraction. Electric systems utilize batteries and generators to supply power, enabling more precise control, reduced weight, and improved fuel efficiency by minimizing engine load. Comparative analysis shows electric systems enhance aircraft performance through better energy management and lower maintenance costs, while bleed air systems remain reliable but less efficient in modern aviation contexts.

Impact on Aircraft Environmental Control Systems

Bleed air systems in aircraft environmental control systems (ECS) use compressed air from the engines to provide cabin pressurization, heating, and cooling, impacting fuel efficiency due to engine performance penalties. Electric ECS technology eliminates bleed air extraction, improving fuel efficiency and reducing maintenance complexity while enabling more precise environmental control and quieter operation. Transitioning to electric systems supports more sustainable aviation by lowering emissions and increasing overall system reliability and responsiveness.

Maintenance, Reliability, and Lifecycle Costs

Bleed air systems require extensive maintenance due to complex ducting and high-temperature components, resulting in increased downtime and higher lifecycle costs. Electric systems offer improved reliability with fewer moving parts and simpler architecture, reducing maintenance frequency and associated expenses. Over the aircraft's operational life, electric systems demonstrate lower total costs due to enhanced durability and streamlined servicing processes.

Weight and Space Considerations

Bleed air systems generally require extensive ductwork, valves, and compressors, contributing to increased aircraft weight and occupying significant space within the airframe. Electric systems eliminate the need for heavy pneumatic components, reducing overall weight and freeing up valuable space for other equipment or payload. The shift towards electric systems enhances design flexibility and efficiency by optimizing weight distribution and maximizing internal aircraft volume.

Safety, Redundancy, and Failure Modes

Bleed air systems, commonly used in aircraft environmental control, pose safety risks due to high-temperature, high-pressure air potentially causing engine damage or cabin air contamination from engine oil leaks. Electric systems offer improved safety by eliminating bleed air hazards, providing cleaner cabin air and reduced fire risk. Redundancy in electric systems is achieved through multiple independent power sources, enhancing fault tolerance, whereas bleed air systems rely heavily on engine operation, increasing failure mode vulnerability during engine faults or bleed valve malfunctions.

Future Trends: Electrification in Aerospace Engineering

Future trends in aerospace engineering emphasize electrification, shifting from traditional bleed air systems to electric systems for improved efficiency and environmental sustainability. Electric systems reduce fuel consumption and carbon emissions by eliminating the need to extract air from engine compressors, leading to quieter, lighter, and more reliable aircraft designs. Advancements in high-power electric components and battery technology support this transition, enabling more electric aircraft (MEA) architectures in commercial and military aviation sectors.

Pneumatic power distribution

Pneumatic power distribution in bleed air systems relies on high-pressure air from engines for aircraft environmental control and anti-icing, while electric systems use distributed electrical power for precise, efficient, and lower-weight pneumatic functions replacement.

Electro-thermal ice protection

Electro-thermal ice protection systems offer precise, energy-efficient ice removal compared to traditional bleed air systems by using electrical heating elements integrated into aircraft surfaces for faster response and reduced impact on engine performance.

Environmental Control System (ECS)

Electric Environmental Control Systems (ECS) reduce fuel consumption and emissions compared to traditional bleed air systems by eliminating engine bleed air extraction and improving overall aircraft environmental efficiency.

Ram Air Turbine (RAT) integration

Ram Air Turbine (RAT) integration in bleed air systems enhances emergency power reliability by providing aerodynamic energy conversion, while electric systems rely on battery-backed generators for redundant power supply.

More Electric Aircraft (MEA)

More Electric Aircraft (MEA) replace traditional bleed air systems with advanced electrical systems to improve efficiency, reduce maintenance, and enhance environmental performance.

Air cycle machine (ACM)

Air cycle machines (ACMs) in bleed air systems utilize compressed engine air for aircraft cooling, whereas electric systems rely on electrically driven compressors, offering improved energy efficiency and reduced engine load.

Thermal management architecture

Electric thermal management systems offer precise temperature control and improved energy efficiency compared to traditional bleed air systems, which rely on high-pressure engine air and result in higher thermal losses and reduced overall aircraft performance.

On-board power generation

Electric systems enhance on-board power generation efficiency by eliminating the energy losses and maintenance demands associated with traditional bleed air systems.

Turbine extraction losses

Bleed air systems reduce turbine efficiency by extracting high-pressure air from compressor stages, causing turbine extraction losses that electric systems avoid by using independent power sources.

Electrified wing anti-ice

Electrified wing anti-ice systems offer increased energy efficiency and reduced maintenance compared to traditional bleed air systems by directly heating wing surfaces without compromising engine performance.

bleed air systems vs electric systems Infographic

njnir.com

njnir.com