Turboelectric propulsion integrates a gas turbine engine with electric motors, offering enhanced efficiency and power density for aerospace applications. All-electric propulsion relies solely on electric energy storage and conversion, leading to zero emissions but limited by current battery energy density. Turboelectric systems strike a balance between energy density and environmental impact, making them a promising solution for next-generation aircraft.

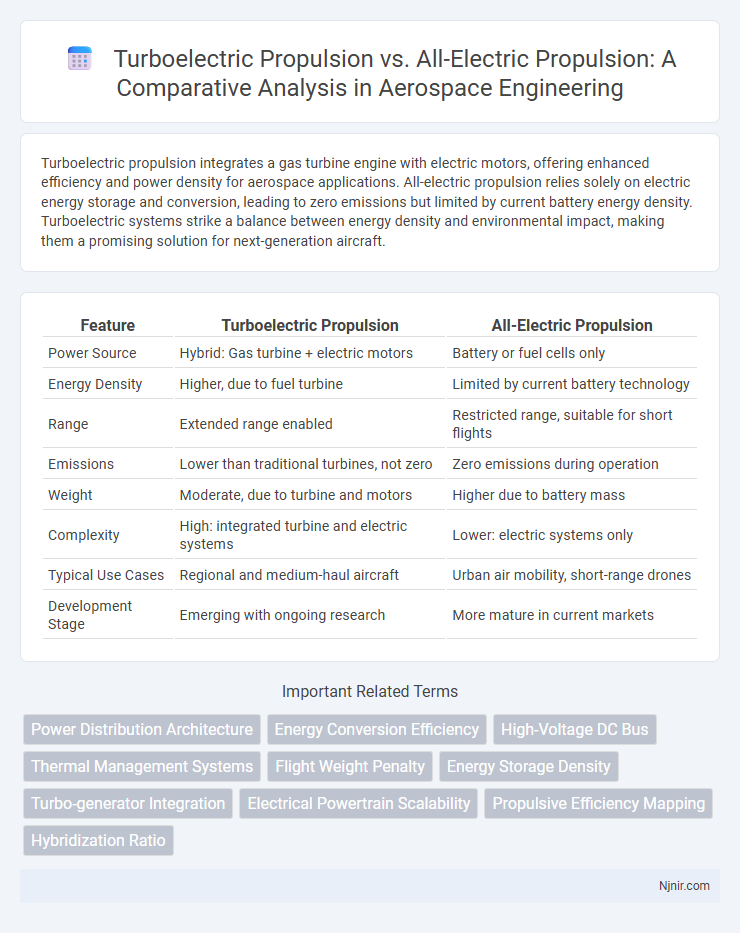

Table of Comparison

| Feature | Turboelectric Propulsion | All-Electric Propulsion |

|---|---|---|

| Power Source | Hybrid: Gas turbine + electric motors | Battery or fuel cells only |

| Energy Density | Higher, due to fuel turbine | Limited by current battery technology |

| Range | Extended range enabled | Restricted range, suitable for short flights |

| Emissions | Lower than traditional turbines, not zero | Zero emissions during operation |

| Weight | Moderate, due to turbine and motors | Higher due to battery mass |

| Complexity | High: integrated turbine and electric systems | Lower: electric systems only |

| Typical Use Cases | Regional and medium-haul aircraft | Urban air mobility, short-range drones |

| Development Stage | Emerging with ongoing research | More mature in current markets |

Introduction to Next-Generation Aircraft Propulsion

Turboelectric propulsion integrates gas turbines with electric motors to drive aircraft propellers or fans, enabling enhanced fuel efficiency and reduced emissions in next-generation aircraft. All-electric propulsion relies solely on electric power, typically from batteries or fuel cells, offering zero-emission operation but facing challenges in energy density and endurance. Both technologies represent critical advancements toward sustainable aviation by optimizing energy use and minimizing environmental impact.

Fundamentals of Turboelectric Propulsion

Turboelectric propulsion integrates a gas turbine engine with an electric generator, powering electric motors connected to the aircraft's propellers or fans. This system converts mechanical energy from the turbine into electrical energy, enabling flexible power distribution and potentially improved fuel efficiency compared to conventional systems. The core advantage lies in decoupling the turbine speed from propeller speed, optimizing performance and reducing emissions in aviation applications.

Principles of All-Electric Propulsion

All-electric propulsion systems operate by converting electrical energy stored in batteries or generated onboard directly into mechanical power through electric motors, eliminating the need for combustion engines. These systems enable precise control of motor speed and torque, enhancing efficiency and reducing emissions compared to traditional propulsion methods. Key components include high-capacity batteries, power electronics, and electric drivetrains designed for reliability and energy density optimization.

Key Technological Components

Turboelectric propulsion relies on gas turbines driving electrical generators that supply power to electric motors connected to propellers or fans, integrating components such as advanced power electronics, high-speed generators, and efficient thermal management systems. All-electric propulsion systems use batteries or fuel cells to power electric motors directly, demanding high energy density storage solutions, robust motor controllers, and lightweight, high-performance power electronics. Key technological components distinguishing turboelectric systems include turbo-machinery coupled with power conversion units, while all-electric propulsion emphasizes energy storage innovations and optimized electric drivetrain architecture.

Energy Sources and Power Distribution

Turboelectric propulsion systems utilize a gas turbine engine to generate electricity that powers electric motors driving the propellers, enabling flexible power distribution and efficient energy conversion from jet fuel. All-electric propulsion relies solely on stored electrical energy, typically from batteries or fuel cells, to power electric motors, emphasizing energy density and battery capacity as critical performance factors. The key distinction lies in turboelectric's hybrid energy source combining combustion and electric power generation, while all-electric propulsion depends entirely on onboard electrical storage for propulsion.

Efficiency Comparison: Turboelectric vs All-Electric

Turboelectric propulsion systems integrate a gas turbine engine driving an electric generator to power electric motors, achieving higher overall efficiency by combining thermal and electrical energy conversion. All-electric propulsion relies solely on battery-stored electrical energy, often resulting in lower efficiency due to energy losses during battery charging and discharging cycles. Turboelectric setups deliver superior efficiency in long-range applications by optimizing fuel consumption and reducing weight compared to all-electric systems, which excel in short-range and zero-emission scenarios.

Weight, Range, and Performance Impacts

Turboelectric propulsion systems integrate gas turbines with electric motors, resulting in optimized weight distribution that can reduce overall aircraft mass compared to all-electric systems burdened by heavy batteries. This configuration enables extended range capabilities by leveraging the high energy density of jet fuel, surpassing the current limitations of battery energy storage in all-electric propulsion. Performance-wise, turboelectric propulsion offers improved power management and redundancy, enhancing thrust efficiency and operational reliability over purely electric alternatives.

Environmental and Emissions Considerations

Turboelectric propulsion systems reduce carbon emissions by integrating gas turbines with electric generators, allowing more efficient energy use and decreased fuel consumption compared to conventional engines. All-electric propulsion offers zero in-flight emissions, relying entirely on stored electrical energy, thus eliminating greenhouse gases during operation but faces challenges related to current battery energy density and lifecycle environmental impacts. Both technologies significantly contribute to lowering aviation's environmental footprint, with turboelectric systems providing a transitional solution while advancements in battery technology enhance the sustainability of all-electric propulsion.

Industry Challenges and Recent Developments

Turboelectric propulsion faces challenges in integrating complex power electronics and thermal management systems, impacting aircraft weight and efficiency. All-electric propulsion struggles with energy density limitations in current battery technologies, restricting range and payload capacity. Recent developments include advanced hybrid architectures and high-power-density electric motors, aiming to enhance performance while reducing carbon emissions in aviation.

Future Prospects and Adoption Pathways

Turboelectric propulsion offers significant future prospects due to its potential for higher efficiency and reduced emissions by integrating gas turbines with electric drive systems, making it suitable for long-haul aviation. All-electric propulsion, relying solely on battery or fuel cell energy, faces current limitations in energy density but benefits from rapid advances in battery technology and renewable energy integration, favoring short-haul and urban air mobility. Adoption pathways for turboelectric systems involve incremental integration with existing aircraft designs and infrastructure adaptation, while all-electric propulsion demands breakthrough improvements in energy storage and charging infrastructure to achieve widespread commercial viability.

Power Distribution Architecture

Turboelectric propulsion uses centralized power generators distributing electricity through a network to electric motors driving propulsion, while all-electric propulsion relies on independent electric power sources directly powering each motor, emphasizing distinct power distribution architectures for efficiency and redundancy.

Energy Conversion Efficiency

Turboelectric propulsion achieves higher energy conversion efficiency by integrating gas turbines with electric generators to optimize power distribution, whereas all-electric propulsion relies solely on battery-stored electricity, often resulting in lower overall efficiency due to energy losses in storage and conversion.

High-Voltage DC Bus

Turboelectric propulsion systems utilize a high-voltage DC bus to efficiently distribute power between turbines and electric motors, offering greater flexibility and reduced weight compared to traditional all-electric propulsion systems limited by battery capacity and voltage constraints.

Thermal Management Systems

Turboelectric propulsion systems require advanced thermal management systems to efficiently dissipate heat generated by both the gas turbine and electric components, whereas all-electric propulsion relies heavily on optimized cooling solutions to manage heat from high-power electric motors and batteries.

Flight Weight Penalty

Turboelectric propulsion systems reduce flight weight penalties compared to all-electric propulsion by distributing power more efficiently through lighter electrical transmission while minimizing the need for heavy batteries.

Energy Storage Density

Turboelectric propulsion offers lower energy storage density requirements compared to all-electric propulsion, enabling lighter and more efficient aircraft designs.

Turbo-generator Integration

Turboelectric propulsion integrates turbo-generators to convert mechanical energy from the engine into electrical power, enhancing efficiency and reducing weight compared to all-electric propulsion systems that rely solely on battery-stored electricity.

Electrical Powertrain Scalability

Turboelectric propulsion offers greater electrical powertrain scalability than all-electric propulsion by integrating gas turbines with electric generators, enabling higher power outputs and efficient energy distribution for large aircraft applications.

Propulsive Efficiency Mapping

Turboelectric propulsion demonstrates higher propulsive efficiency in mid-to-high power regimes compared to all-electric propulsion due to optimized energy distribution between turbine and electric motor systems.

Hybridization Ratio

Turboelectric propulsion systems exhibit higher hybridization ratios than all-electric propulsion by integrating gas turbines with electric motors to optimize fuel efficiency and reduce emissions.

Turboelectric Propulsion vs All-Electric Propulsion Infographic

njnir.com

njnir.com