Single-stage-to-orbit (SSTO) vehicles offer streamlined design and reduced launch complexity by eliminating the need for staging events, potentially enhancing reliability and lowering operational costs. However, SSTO systems face significant engineering challenges related to weight optimization and propulsion efficiency to achieve the necessary delta-v for orbit insertion. In contrast, two-stage-to-orbit (TSTO) vehicles benefit from dividing the mass and fuel load between stages, enabling higher payload capacity and more flexible mission profiles despite increased mechanical complexity and manufacturing costs.

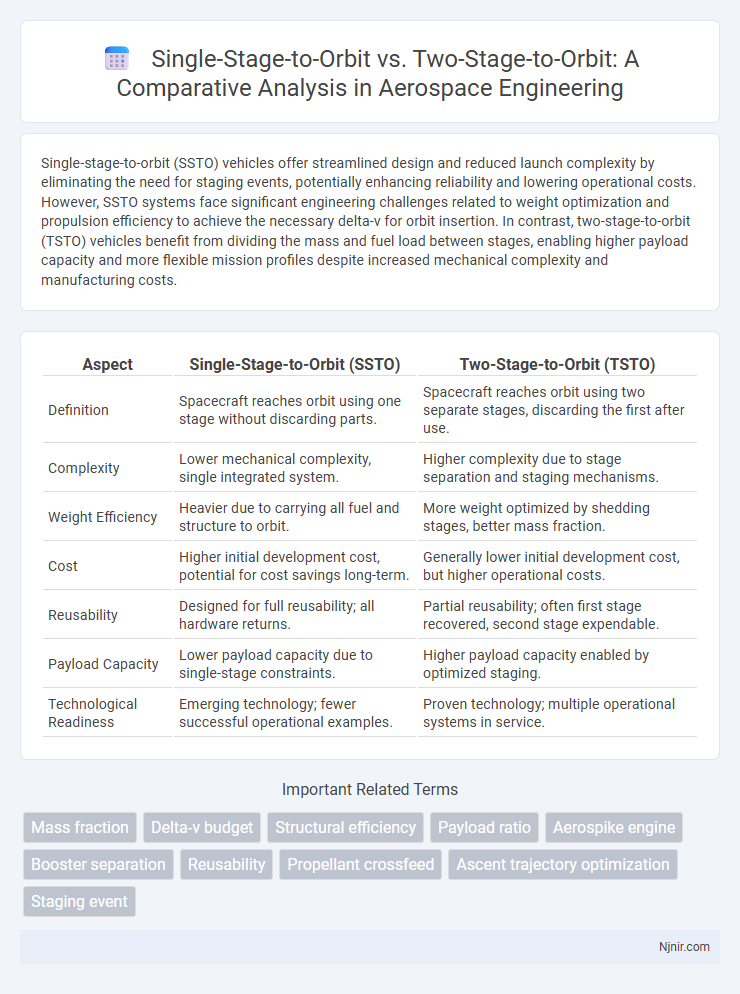

Table of Comparison

| Aspect | Single-Stage-to-Orbit (SSTO) | Two-Stage-to-Orbit (TSTO) |

|---|---|---|

| Definition | Spacecraft reaches orbit using one stage without discarding parts. | Spacecraft reaches orbit using two separate stages, discarding the first after use. |

| Complexity | Lower mechanical complexity, single integrated system. | Higher complexity due to stage separation and staging mechanisms. |

| Weight Efficiency | Heavier due to carrying all fuel and structure to orbit. | More weight optimized by shedding stages, better mass fraction. |

| Cost | Higher initial development cost, potential for cost savings long-term. | Generally lower initial development cost, but higher operational costs. |

| Reusability | Designed for full reusability; all hardware returns. | Partial reusability; often first stage recovered, second stage expendable. |

| Payload Capacity | Lower payload capacity due to single-stage constraints. | Higher payload capacity enabled by optimized staging. |

| Technological Readiness | Emerging technology; fewer successful operational examples. | Proven technology; multiple operational systems in service. |

Introduction to Orbital Launch Systems

Single-stage-to-orbit (SSTO) launch systems aim to reach orbit using a single rocket without discarding any hardware, offering potential cost reductions and increased reusability but facing significant engineering challenges related to weight and fuel efficiency. Two-stage-to-orbit (TSTO) systems separate the launch vehicle into two segments, shedding mass during ascent to improve payload capacity and reliability, making them the current industry standard for orbital access. Orbital launch systems rely heavily on propulsion technology, structural materials, and aerodynamics to balance performance and cost in delivering payloads to orbit.

Defining Single-Stage-to-Orbit (SSTO) and Two-Stage-to-Orbit (TSTO)

Single-Stage-to-Orbit (SSTO) vehicles achieve orbit using a single rocket stage without jettisoning parts, relying on advanced lightweight materials and high-efficiency engines to balance fuel capacity and payload. Two-Stage-to-Orbit (TSTO) systems employ a multistage approach, discarding the first stage after its fuel is expended, which reduces mass and improves overall efficiency for reaching orbit. SSTO designs focus on simplicity and reusability, whereas TSTO structures optimize performance through staged propulsion and mass reduction during ascent.

Historical Evolution of SSTO and TSTO Concepts

The historical evolution of Single-Stage-To-Orbit (SSTO) and Two-Stage-To-Orbit (TSTO) concepts traces back to early rocketry research in the mid-20th century, with SSTO gaining attention for its simplicity and potential cost savings by eliminating staging complexity. TSTO became the dominant design due to practical performance advantages, with vehicles like the Saturn V and Space Shuttle demonstrating successful multistage operations that effectively manage payload capacity and fuel efficiency. Advancements in materials and propulsion systems continue to influence SSTO research, aiming to overcome its technical challenges related to mass fractions and engine efficiency that initially limited its widespread adoption.

Core Design Principles and Engineering Challenges

Single-stage-to-orbit (SSTO) vehicles emphasize simplicity and reusability by using a single propulsion system to reach orbit, demanding an exceptionally high mass fraction and advanced lightweight materials to minimize structural weight. Two-stage-to-orbit (TSTO) designs split the ascent into two phases, allowing optimized propulsion and weight distribution for each stage but requiring complex separation mechanisms and staging logistics. Engineering challenges for SSTO include achieving sufficient delta-v with constrained fuel loads, while TSTO must manage aerodynamic stability during staging and integrate multi-engine reliability.

Mass Fraction and Propulsion Efficiency Analysis

Single-stage-to-orbit (SSTO) vehicles require exceptionally high mass fractions, often exceeding 90%, due to the need to carry all propellant and structural mass in a single vehicle, which challenges propulsion efficiency and structural materials. Two-stage-to-orbit (TSTO) systems improve overall propulsion efficiency by dividing the ascent into two phases, allowing each stage to operate at optimal mass ratios and specific impulses, reducing the lift-off mass fraction constraints. Analysis shows that TSTO architectures benefit from lower structural coefficients and staged propulsion designs, enabling improved payload capacity and mission flexibility compared to SSTO counterparts.

Reusability and Operational Cost Comparisons

Single-stage-to-orbit (SSTO) vehicles offer potential reusability advantages by simplifying design and reducing refurbishment needs, as they avoid staging events that cause structural wear. Two-stage-to-orbit (TSTO) systems, while more complex, typically allow for optimized propulsion and payload capacity, but involve higher operational costs due to multiple vehicle recoveries and more intricate refurbishment processes. Operational cost comparisons favor SSTO for rapid turnaround and lower maintenance, whereas TSTO systems may incur greater expenses but benefit from proven performance and scalability.

Payload Capacity and Performance Metrics

Single-Stage-to-Orbit (SSTO) vehicles typically feature lower payload capacity compared to Two-Stage-to-Orbit (TSTO) systems due to the need to carry all propellant from launch without discarding mass. SSTO designs emphasize reusability and simplicity but face challenges in achieving high delta-v and mass fraction, resulting in performance metrics that often limit delivered payload to orbit. Conversely, TSTO architectures leverage staging to shed weight mid-flight, enhancing overall efficiency and allowing greater payload capacity and higher specific impulse performance metrics.

Case Studies: Notable SSTO and TSTO Launch Vehicles

The Space Shuttle is a prime example of a two-stage-to-orbit (TSTO) vehicle, utilizing a reusable orbiter and solid rocket boosters to achieve orbit efficiently; in contrast, the X-33 program aimed to develop a single-stage-to-orbit (SSTO) craft with its experimental lifting body design but was ultimately canceled due to technical challenges. Another notable TSTO vehicle is the Falcon 9, which employs a reusable first stage and an expendable second stage, demonstrating cost-effective orbital launches through stage separation. The Skylon project represents a modern SSTO concept, focusing on a fully reusable spaceplane utilizing SABRE engines for combined air-breathing and rocket propulsion to minimize launch costs and complexity.

Technological Innovations Impacting SSTO and TSTO Feasibility

Technological innovations such as advanced composite materials and reusable engine designs significantly enhance the feasibility of single-stage-to-orbit (SSTO) vehicles by reducing weight and improving thrust-to-weight ratios. Two-stage-to-orbit (TSTO) systems benefit from modular advancements, including optimized staging techniques and improved thermal protection systems that increase payload capacity and mission flexibility. Breakthroughs in propulsion, such as hybrid and aerospike engines, critically impact both SSTO and TSTO by enabling more efficient fuel consumption and greater operational reliability.

Future Prospects and Industry Trends in Orbital Launch Systems

Single-stage-to-orbit (SSTO) vehicles promise simplified design and reduced launch costs by eliminating separation events, but face challenges in achieving the necessary mass fraction and propulsion efficiency with current technology. Two-stage-to-orbit (TSTO) systems dominate the market, benefiting from proven reliability and flexibility in payload capacity, with advancements in reusable boosters driving cost reductions. Emerging industry trends prioritize hybrid approaches, innovative materials, and enhanced engine performance to bridge SSTO feasibility gaps while leveraging TSTO's operational maturity for near-term commercial and governmental launch demands.

Mass fraction

Single-stage-to-orbit (SSTO) vehicles typically face higher mass fraction challenges than two-stage-to-orbit (TSTO) systems, as SSTOs require a greater proportion of their total launch mass to be allocated to propellant to achieve orbit without staging.

Delta-v budget

Single-stage-to-orbit vehicles require significantly higher delta-v budgets than two-stage-to-orbit systems due to the absence of mass shedding, resulting in lower payload efficiency and increased fuel consumption.

Structural efficiency

Single-stage-to-orbit vehicles generally exhibit lower structural efficiency due to the need for heavier, more robust structures to carry all propellant from launch to orbit, whereas two-stage-to-orbit systems achieve higher structural efficiency by shedding weight through stage separation.

Payload ratio

Single-stage-to-orbit vehicles typically have lower payload ratios, often below 10%, compared to two-stage-to-orbit systems that can achieve payload ratios exceeding 15% by optimizing mass distribution and staging efficiency.

Aerospike engine

The Aerospike engine enhances single-stage-to-orbit (SSTO) efficiency by maintaining optimal sea-level and vacuum performance, unlike traditional bell nozzles typically used in two-stage-to-orbit (TSTO) systems.

Booster separation

Single-stage-to-orbit vehicles eliminate booster separation complexity by relying on a single integrated propulsion system, whereas two-stage-to-orbit designs require precise booster separation to ensure successful orbital insertion and maximize payload capacity.

Reusability

Single-stage-to-orbit vehicles offer higher reusability potential by eliminating the need for multiple vehicle separations, reducing refurbishment complexity compared to two-stage-to-orbit systems.

Propellant crossfeed

Propellant crossfeed in two-stage-to-orbit systems enhances overall efficiency by transferring fuel from the first stage to the second during ascent, reducing the second stage's mass at separation unlike single-stage-to-orbit vehicles that carry all propellant onboard without crossfeed benefits.

Ascent trajectory optimization

Single-stage-to-orbit ascent trajectory optimization minimizes total mass by balancing propellant efficiency and aerodynamic drag, whereas two-stage-to-orbit allows discrete trajectory phases optimizing individual stage performance for improved payload fraction.

Staging event

Single-stage-to-orbit vehicles eliminate the complex staging event required by two-stage-to-orbit rockets, enhancing system simplicity and reducing potential mechanical failure points during ascent.

single-stage-to-orbit vs two-stage-to-orbit Infographic

njnir.com

njnir.com