Two-Stage-To-Orbit (TSTO) vehicles offer enhanced payload capacity and reduced structural stress by dividing the ascent into separate stages, allowing each to be optimized for different flight regimes. Single-Stage-To-Orbit (SSTO) systems simplify design by eliminating staging but face significant challenges in achieving the necessary mass fraction and efficient propulsion. Advances in lightweight materials and high-performance engines are crucial to making SSTO more viable, whereas TSTO remains the preferred choice for current heavy-lift missions due to its proven reliability.

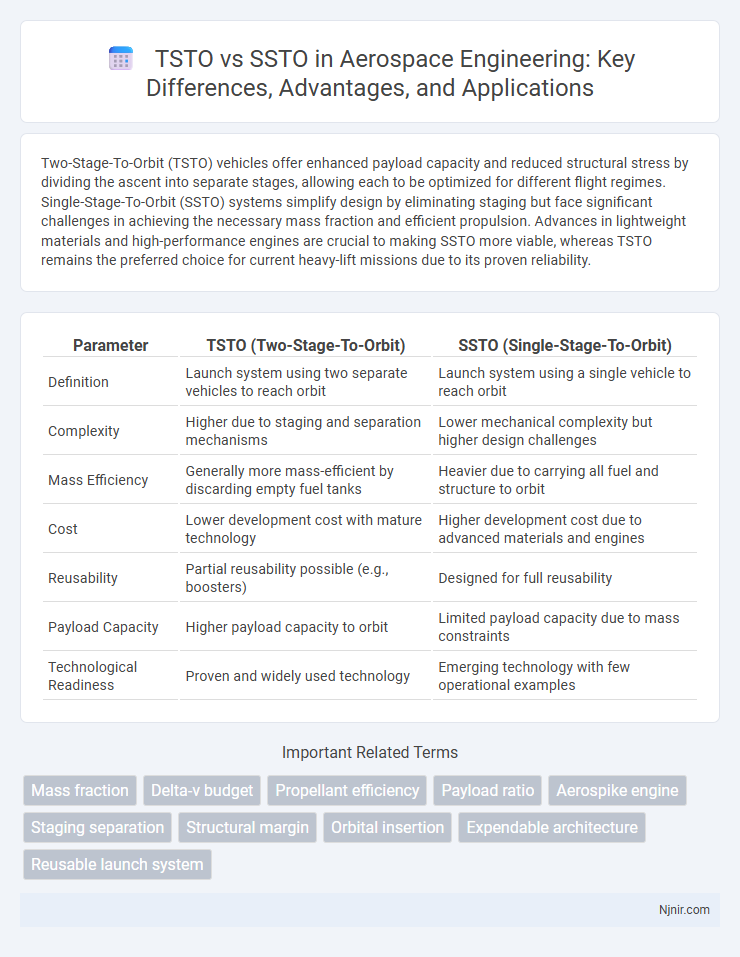

Table of Comparison

| Parameter | TSTO (Two-Stage-To-Orbit) | SSTO (Single-Stage-To-Orbit) |

|---|---|---|

| Definition | Launch system using two separate vehicles to reach orbit | Launch system using a single vehicle to reach orbit |

| Complexity | Higher due to staging and separation mechanisms | Lower mechanical complexity but higher design challenges |

| Mass Efficiency | Generally more mass-efficient by discarding empty fuel tanks | Heavier due to carrying all fuel and structure to orbit |

| Cost | Lower development cost with mature technology | Higher development cost due to advanced materials and engines |

| Reusability | Partial reusability possible (e.g., boosters) | Designed for full reusability |

| Payload Capacity | Higher payload capacity to orbit | Limited payload capacity due to mass constraints |

| Technological Readiness | Proven and widely used technology | Emerging technology with few operational examples |

Introduction to TSTO and SSTO Concepts

Two-Stage-To-Orbit (TSTO) and Single-Stage-To-Orbit (SSTO) represent distinct spacecraft launch methodologies. TSTO employs two separate vehicles or stages, where the first stage boosts payload to a certain altitude before the second stage carries it into orbit, optimizing fuel efficiency and payload capacity. SSTO relies on a single, fully reusable vehicle capable of reaching orbit without jettisoning stages, posing engineering challenges due to weight constraints and propulsion system demands.

Historical Development of Aerospace Launch Systems

The historical development of aerospace launch systems highlights the distinction between Two-Stage-To-Orbit (TSTO) and Single-Stage-To-Orbit (SSTO) vehicles, with TSTO designs gaining prominence due to their enhanced payload capacity and fuel efficiency. Early Cold War-era programs, such as the Saturn V rocket, embodied the TSTO approach, utilizing multiple stages to achieve orbit by shedding weight progressively. SSTO concepts, exemplified by experimental vehicles like the X-33, have faced engineering challenges in materials and propulsion that limited their operational success despite potential benefits of simplified reusability.

Fundamental Differences Between TSTO and SSTO

Two-Stage-to-Orbit (TSTO) systems utilize separate launch vehicles for each flight stage, significantly reducing the structural and fuel mass required for orbital insertion compared to Single-Stage-to-Orbit (SSTO) vehicles, which must carry all propellant and structural components from launch to orbit. TSTO designs benefit from optimized engine performance and staging efficiency, allowing higher payload fractions and lower mass ratios, while SSTO systems face challenges of achieving sufficient delta-v with a fully reusable structure. Fundamental differences emphasize TSTO's complexity with stage separation mechanisms versus SSTO's engineering demands for lightweight materials and high-specific impulse propulsion to overcome the gravity and atmospheric drag losses in a single continuous ascent.

Performance and Efficiency Comparisons

TSTO (Two-Stage-To-Orbit) vehicles generally exhibit higher overall payload capacity and greater mission flexibility compared to SSTO (Single-Stage-To-Orbit) designs, due to optimized staging that reduces mass and maximizes fuel efficiency during ascent. SSTO vehicles face significant engineering challenges in achieving the required delta-v without shedding mass, resulting in lower payload fractions and often higher structural weight. Performance efficiency in TSTO is enhanced by stage-specific propulsion systems tailored for atmospheric and vacuum conditions, whereas SSTO must compromise on engine optimization to function across varying altitudes.

Propulsion Technologies for TSTO and SSTO Vehicles

Two-stage-to-orbit (TSTO) vehicles use separate propulsion systems optimized for each flight stage, typically combining air-breathing engines or rockets for the first stage and high-efficiency rocket engines for the second stage to enhance overall performance and reduce mass. Single-stage-to-orbit (SSTO) vehicles rely on a single, highly efficient propulsion system that must provide sufficient thrust-to-weight ratio and specific impulse to achieve orbit without discarding hardware. Advanced propulsion technologies for SSTO vehicles often include combined-cycle engines or highly lightweight cryogenic rocket engines, balancing the challenge of sustained atmospheric and vacuum operation within a single system.

Structural Design Challenges

Two-Stage-to-Orbit (TSTO) vehicles separate launch and orbital insertion phases, enabling optimized structural design by reducing stresses on each stage, whereas Single-Stage-to-Orbit (SSTO) systems face significant challenges balancing weight, strength, and thermal protection within one airframe. SSTO designs require ultra-lightweight, high-strength materials such as carbon composites and advanced alloys to withstand intense aerodynamic loads and thermal cycling without the benefit of stage separation to shed weight. The structural complexity of SSTO is compounded by the need for integrated fuel storage and propulsion systems that maintain integrity throughout ascent and orbital insertion, making thermal and mechanical stresses far more demanding than in TSTO designs.

Cost Analysis: Development, Launch, and Reusability

TSTO (Two-Stage-To-Orbit) vehicles generally exhibit lower development costs due to proven modular designs, whereas SSTO (Single-Stage-To-Orbit) demands advanced materials and propulsion, elevating initial R&D expenses significantly. Launch costs for TSTO are often reduced by splitting payload delivery between stages, optimizing fuel efficiency and allowing partial reuse, while SSTO faces higher operational costs due to heavier fuel loads and limited payload capacity. In terms of reusability, TSTO platforms benefit from stage recovery and refurbishment, which amortizes expenses over multiple flights, whereas SSTO reusability is constrained by thermal stress and structural wear, increasing maintenance expenditures.

Mission Flexibility and Payload Capabilities

TSTO (Two-Stage-to-Orbit) vehicles offer greater mission flexibility by separating propulsion stages, allowing optimization for different flight regimes and increased payload capacity due to staged mass reduction. SSTO (Single-Stage-to-Orbit) designs face limitations in payload mass fraction because they must carry all fuel and structural mass in one stage, constraining payload capabilities and reducing adaptability for varied mission profiles. As a result, TSTO architectures dominate heavy-lift and diverse orbital missions, while SSTO systems are better suited for smaller payloads and rapid, reusable access to low Earth orbit.

Real-World Examples and Case Studies

Two-Stage-To-Orbit (TSTO) vehicles like the Space Shuttle and Falcon 9 demonstrate more practical and scalable solutions for orbital launches compared to Single-Stage-To-Orbit (SSTO) concepts, which remain mostly theoretical or experimental. Real-world TSTO examples emphasize payload efficiency and reusability, with SpaceX's Falcon 9 achieving rapid turnaround times and cost reduction through stage separation technology. Studies highlight SSTO challenges such as high mass fractions and thermal protection complexity, evident in projects like the X-33, which ultimately failed to reach operational status.

Future Trends in Orbital Launch Architectures

TSTO (Two-Stage-to-Orbit) and SSTO (Single-Stage-to-Orbit) architectures are evolving with advancements in reusable rocket technology and lightweight materials, driving future trends in orbital launches. Innovations in composite propellants and AI-driven flight optimization favor TSTO designs for cost-effective, reliable access to orbit, while SSTO remains a target for minimal operational complexity and rapid turnaround. Emerging hybrid propulsion systems and additive manufacturing are expected to blur the distinction, enabling more efficient, scalable orbital launch solutions.

Mass fraction

SSTOs typically have lower mass fractions due to the need for heavier thermal protection and structural reinforcements compared to the more mass-efficient, single-stage-to-orbit (TSTO) vehicles that use multiple stages to discard weight during ascent.

Delta-v budget

TSTO launch vehicles typically achieve higher total Delta-v efficiency by optimizing stage separation and engine performance, while SSTO vehicles require significantly larger structural mass fractions to reach orbit due to limited Delta-v budgets.

Propellant efficiency

SSTOs achieve higher propellant efficiency by minimizing mass and bypassing staging losses compared to TSTOs, which require additional fuel to lift multiple rocket stages.

Payload ratio

SSTOs typically have lower payload ratios than TSTOs due to the mass penalties of single-stage design constraints impacting fuel efficiency and structural weight.

Aerospike engine

Aerospike engines enable TSTO rockets to achieve higher payload capacity and improved altitude performance compared to SSTO vehicles by optimizing thrust efficiency and reducing drag.

Staging separation

TSTO features a clear staging separation with multiple rocket stages jettisoned sequentially, while SSTO relies on a single stage without separation for reusability.

Structural margin

SSTOs typically have lower structural margins than TSTOs due to their higher thermal and mechanical stresses during single-stage ascent and reentry.

Orbital insertion

SSTO vehicles achieve orbital insertion in a single continuous flight without staging, while TSTO vehicles rely on multiple stages to efficiently reach orbit by shedding weight during ascent.

Expendable architecture

Expendable architecture in TSTO utilizes separate stages discarded after use to optimize payload capacity, whereas SSTO relies on a single reusable vehicle requiring advanced materials and propulsion to achieve orbit without staging.

Reusable launch system

Reusable launch systems like TSTO maximize payload efficiency by separating stages, while SSTO offers simpler design but faces greater technical challenges in achieving orbital velocity.

TSTO vs SSTO Infographic

njnir.com

njnir.com