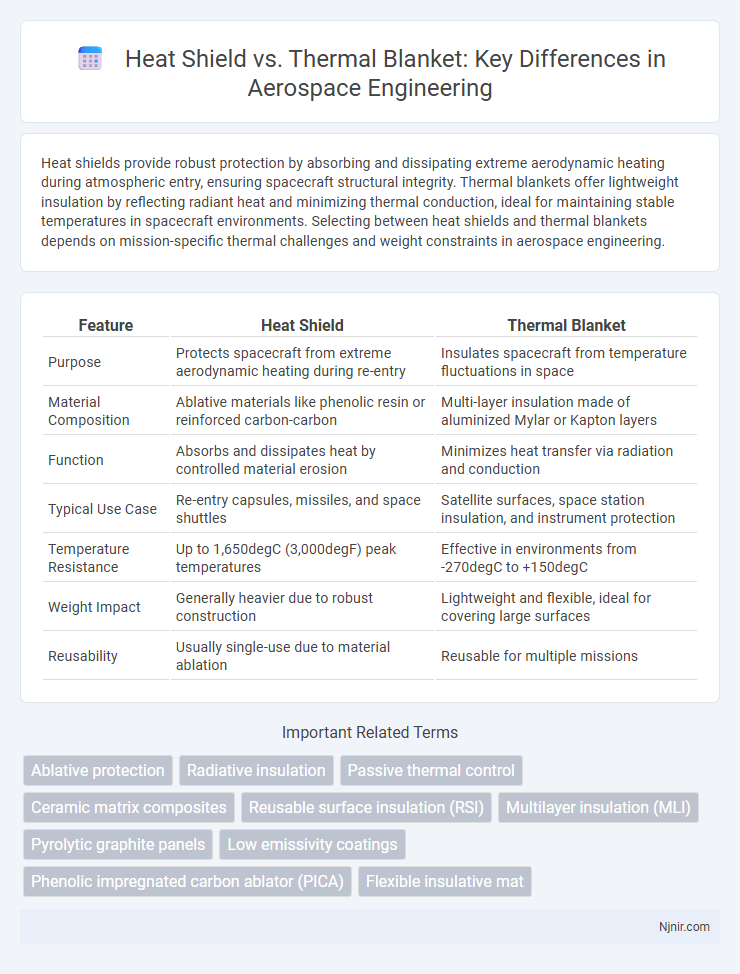

Heat shields provide robust protection by absorbing and dissipating extreme aerodynamic heating during atmospheric entry, ensuring spacecraft structural integrity. Thermal blankets offer lightweight insulation by reflecting radiant heat and minimizing thermal conduction, ideal for maintaining stable temperatures in spacecraft environments. Selecting between heat shields and thermal blankets depends on mission-specific thermal challenges and weight constraints in aerospace engineering.

Table of Comparison

| Feature | Heat Shield | Thermal Blanket |

|---|---|---|

| Purpose | Protects spacecraft from extreme aerodynamic heating during re-entry | Insulates spacecraft from temperature fluctuations in space |

| Material Composition | Ablative materials like phenolic resin or reinforced carbon-carbon | Multi-layer insulation made of aluminized Mylar or Kapton layers |

| Function | Absorbs and dissipates heat by controlled material erosion | Minimizes heat transfer via radiation and conduction |

| Typical Use Case | Re-entry capsules, missiles, and space shuttles | Satellite surfaces, space station insulation, and instrument protection |

| Temperature Resistance | Up to 1,650degC (3,000degF) peak temperatures | Effective in environments from -270degC to +150degC |

| Weight Impact | Generally heavier due to robust construction | Lightweight and flexible, ideal for covering large surfaces |

| Reusability | Usually single-use due to material ablation | Reusable for multiple missions |

Introduction to Spacecraft Thermal Protection

Spacecraft thermal protection relies on heat shields and thermal blankets to manage extreme temperature variations during missions. Heat shields absorb and dissipate intense heat during atmospheric re-entry, preventing structural damage, while thermal blankets provide insulation against extreme cold in space. Both components are critical for maintaining spacecraft integrity and ensuring mission success in harsh thermal environments.

Overview of Heat Shields

Heat shields are specialized protective barriers designed to absorb and dissipate intense heat, commonly used in aerospace and automotive applications to safeguard critical components from extreme thermal exposure. Constructed from materials like reinforced carbon-carbon, ceramics, or ablative composites, heat shields provide superior resistance to high temperatures and mechanical stress compared to thermal blankets. Unlike thermal blankets that mainly insulate by trapping air, heat shields actively prevent heat transfer through reflection, radiation absorption, and ablation, making them essential for re-entry vehicles and high-performance engines.

Overview of Thermal Blankets

Thermal blankets are engineered to provide efficient insulation by reflecting radiant heat, commonly used in aerospace applications to protect spacecraft from extreme temperature fluctuations. Unlike heat shields that primarily absorb and dissipate high heat loads during atmospheric re-entry, thermal blankets offer lightweight, flexible thermal protection that minimizes heat transfer through multilayer insulation composed of aluminized Mylar, Kapton, or other specialized materials. Their design emphasizes long-term thermal regulation, preventing heat loss or gain in harsh environments and ensuring critical system stability during extended missions.

Materials Used in Heat Shields

Heat shields primarily use advanced materials such as reinforced carbon-carbon (RCC), ceramic tiles, and ablative composites designed to withstand extreme temperatures and thermal shocks during atmospheric re-entry. These materials offer superior thermal resistance by either dissipating heat through high melting points or by gradually ablating and carrying away heat energy. In contrast, thermal blankets typically employ multi-layer insulation (MLI) composed of aluminized Mylar or Kapton layers that provide lightweight, reflective barriers to minimize heat transfer in less extreme thermal environments.

Materials Used in Thermal Blankets

Thermal blankets primarily utilize materials such as aluminized Mylar, silica fibers, and polyester films to provide effective thermal insulation by reflecting radiant heat. These materials combine high emissivity reduction and low thermal conductivity, ensuring protection in extreme temperature environments. Unlike rigid heat shields made from ceramics or reinforced carbon-carbon composites, thermal blankets offer flexibility and lightweight solutions for spacecraft insulation.

Mechanisms of Heat Dissipation

Heat shields dissipate heat primarily through reflection and radiation, using materials with low thermal conductivity and high emissivity to deflect and emit thermal energy away from protected structures. Thermal blankets function by providing insulation, trapping air within layers of fibrous or foil materials to reduce heat transfer via conduction and convection. Both mechanisms are critical in aerospace applications to manage extreme temperatures during re-entry or high-speed flight.

Comparative Performance: Heat Shield vs Thermal Blanket

Heat shields provide superior protection against intense, high-temperature exposure by reflecting and dissipating heat through materials like reinforced carbon-carbon or ceramic composites, making them ideal for spacecraft re-entry or rocket engines. Thermal blankets, typically made from layers of insulating materials such as aluminized Mylar or silica fibers, offer excellent thermal insulation by trapping heat and preventing heat transfer, best suited for moderate temperature control in spacecraft or sensitive equipment. Overall, heat shields excel in ablative or radiative heat defense under extreme conditions, whereas thermal blankets prioritize lightweight insulation and temperature stabilization.

Application Scenarios in Aerospace Engineering

Heat shields are primarily deployed for high-temperature protection during atmospheric reentry, shielding spacecraft from intense aerodynamic heating by ablating or reflecting heat. Thermal blankets serve as multilayer insulation (MLI) to maintain thermal stability in spacecraft operating in space, minimizing heat loss and protecting sensitive instruments from extreme temperature variations. The choice between heat shield and thermal blanket depends on mission phase and thermal load, with heat shields crucial for reentry scenarios and thermal blankets essential for orbital or deep-space thermal regulation.

Advantages and Limitations of Each System

Heat shields provide superior protection by dissipating and reflecting intense heat through ablative or metallic materials, making them ideal for high-temperature reentries but are often heavier and less reusable. Thermal blankets offer lightweight insulation using layers of low-conductivity fabrics and reflective coatings, enhancing spacecraft thermal control and reducing mass, yet they may lack durability under extreme thermal stress. Choosing between systems depends on mission-specific thermal loads, weight constraints, and reuse requirements.

Innovations and Future Trends in Thermal Protection

Innovations in heat shields include the integration of ultra-high temperature ceramics (UHTCs) and ablative materials designed to withstand extreme atmospheric re-entry heat, enhancing durability and mission adaptability. Thermal blankets are evolving with advancements in multi-layer insulation (MLI) using aerogel-infused layers and nanotechnology coatings to achieve superior thermal resistance while reducing weight. Future trends emphasize the development of smart thermal protection systems that adapt dynamically to temperature fluctuations, leveraging sensors and phase-change materials for real-time thermal management in aerospace applications.

Ablative protection

Ablative heat shields provide superior protection by absorbing and dissipating intense heat through material erosion, unlike thermal blankets that primarily offer insulation without significant ablative properties.

Radiative insulation

Heat shields provide superior radiative insulation by reflecting high-intensity thermal radiation, whereas thermal blankets primarily offer low-weight insulation through multiple reflective layers that reduce radiative heat transfer.

Passive thermal control

Heat shields use ablative or insulative materials to protect spacecraft from intense heat by dissipating or reflecting energy, while thermal blankets provide passive thermal control by insulating and maintaining stable temperatures through multi-layer insulation.

Ceramic matrix composites

Ceramic matrix composites provide superior thermal protection in heat shields compared to thermal blankets by offering higher temperature resistance, enhanced durability, and better structural integrity in aerospace applications.

Reusable surface insulation (RSI)

Reusable Surface Insulation (RSI) uses heat shields made of ceramic tiles to withstand high temperatures during reentry, whereas thermal blankets rely on multi-layer insulation fabrics for lower-temperature spacecraft protection.

Multilayer insulation (MLI)

Multilayer insulation (MLI) enhances thermal protection by using multiple thin layers of reflective materials, making it essential for thermal blankets in spacecraft to minimize heat transfer compared to the thicker, ablative materials used in heat shields.

Pyrolytic graphite panels

Pyrolytic graphite panels outperform traditional thermal blankets in heat shields by providing superior thermal conductivity, enhanced ablation resistance, and lightweight durability for aerospace applications.

Low emissivity coatings

Low emissivity coatings on heat shields reflect thermal radiation to enhance heat resistance, whereas thermal blankets rely primarily on insulating layers without such reflective coatings.

Phenolic impregnated carbon ablator (PICA)

Phenolic impregnated carbon ablator (PICA) is a heat shield material renowned for its superior thermal protection by ablating at high temperatures, unlike thermal blankets which provide insulation without material erosion.

Flexible insulative mat

Flexible insulative mats, such as thermal blankets, provide lightweight, adaptable heat protection by trapping air for insulation, whereas heat shields primarily offer rigid, reflective barriers against high temperatures.

Heat shield vs Thermal blanket Infographic

njnir.com

njnir.com