Friction Stir Welding (FSW) offers superior joint strength and minimal distortion by mechanically stirring materials without melting, making it highly effective for aluminum alloys in aerospace structures. Electron Beam Welding (EBW) provides deep penetration with concentrated heat, enabling precise welding of thick, high-strength aerospace components in vacuum environments. Comparing both, FSW excels in fatigue resistance and environmental safety, while EBW is preferred for complex geometries requiring deep welds and metallurgical control.

Table of Comparison

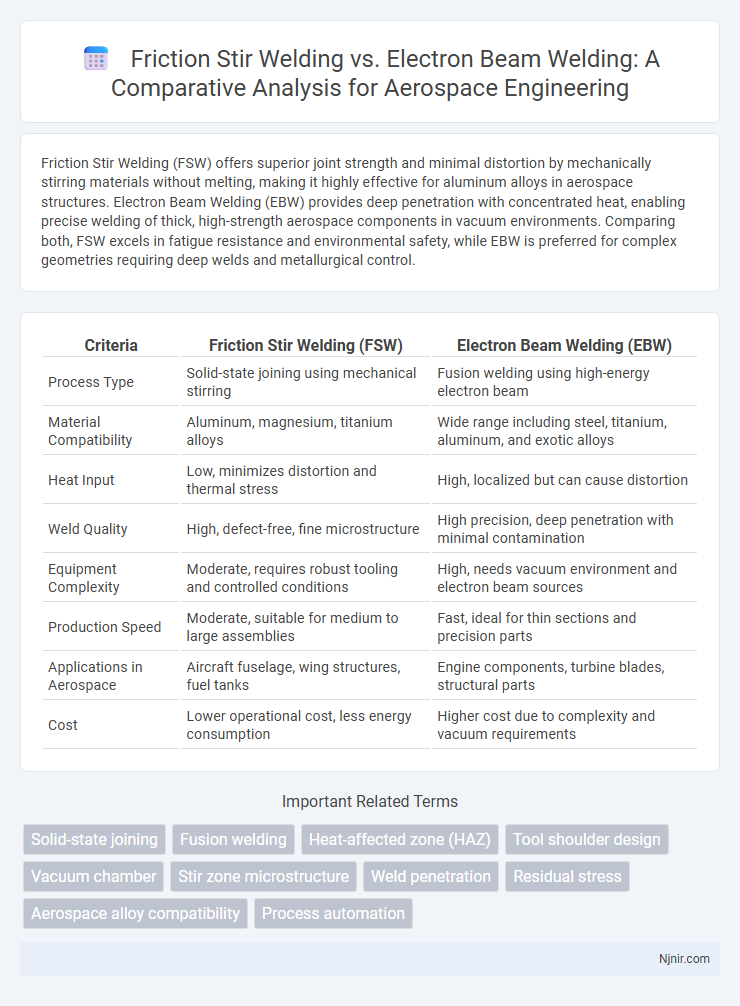

| Criteria | Friction Stir Welding (FSW) | Electron Beam Welding (EBW) |

|---|---|---|

| Process Type | Solid-state joining using mechanical stirring | Fusion welding using high-energy electron beam |

| Material Compatibility | Aluminum, magnesium, titanium alloys | Wide range including steel, titanium, aluminum, and exotic alloys |

| Heat Input | Low, minimizes distortion and thermal stress | High, localized but can cause distortion |

| Weld Quality | High, defect-free, fine microstructure | High precision, deep penetration with minimal contamination |

| Equipment Complexity | Moderate, requires robust tooling and controlled conditions | High, needs vacuum environment and electron beam sources |

| Production Speed | Moderate, suitable for medium to large assemblies | Fast, ideal for thin sections and precision parts |

| Applications in Aerospace | Aircraft fuselage, wing structures, fuel tanks | Engine components, turbine blades, structural parts |

| Cost | Lower operational cost, less energy consumption | Higher cost due to complexity and vacuum requirements |

Introduction to Advanced Welding Techniques in Aerospace

Friction Stir Welding (FSW) and Electron Beam Welding (EBW) are advanced welding techniques crucial in aerospace manufacturing for joining lightweight, high-strength materials like aluminum and titanium alloys. FSW is a solid-state process that generates heat through friction to plasticize and forge materials, resulting in superior mechanical properties and minimal distortion compared to traditional fusion welding. EBW uses a focused electron beam in a vacuum environment to achieve deep, precise welds with high penetration and minimal thermal distortion, making it ideal for complex aerospace components requiring tight tolerances and structural integrity.

Fundamentals of Friction Stir Welding (FSW)

Friction Stir Welding (FSW) relies on a non-consumable rotating tool that generates frictional heat to soften and plasticize the material, enabling solid-state joining without melting. The process involves a specially designed pin and shoulder that traverse the joint line, causing intense plastic deformation and dynamic recrystallization, which refine grain structure and enhance mechanical properties. FSW produces defect-free welds with low distortion and residual stress, making it ideal for aluminum alloys and other heat-sensitive materials compared to Electron Beam Welding (EBW), which uses high-energy electron beams in a vacuum for deep penetration fusion welding.

Principles of Electron Beam Welding (EBW)

Electron Beam Welding (EBW) utilizes a high-velocity electron beam focused on the workpiece, generating intense localized heat that melts and fuses materials with deep penetration and minimal distortion. This vacuum-based process offers precise control over welding parameters, resulting in high-quality joints, especially for thick sections and reactive metals. Unlike Friction Stir Welding, which is a solid-state process relying on mechanical stirring, EBW is a fusion welding technique that achieves metallurgical bonds through electron-induced melting.

Material Compatibility in FSW and EBW

Friction Stir Welding (FSW) excels in joining aluminum alloys, magnesium, copper, and certain steel grades due to its solid-state process, minimizing defects from melting and solidification. Electron Beam Welding (EBW) is highly effective for materials with high melting points such as titanium, stainless steel, and refractory metals, offering deep penetration and narrow weld zones in vacuum environments. Material compatibility in FSW favors soft to medium-hard metals with good plasticity, while EBW accommodates a broader range of high-strength and heat-sensitive materials requiring precise thermal control.

Joint Strength and Structural Integrity Comparison

Friction Stir Welding (FSW) produces joints with high tensile strength and excellent fatigue resistance due to its solid-state process that minimizes defects and grain distortion. Electron Beam Welding (EBW) provides deep penetration and precise control, resulting in strong, narrow welds but may introduce porosity and residual stresses affecting structural integrity. Comparative studies reveal FSW often yields superior joint toughness and consistent mechanical properties, while EBW excels in welding thick sections with high precision where joint strength is critical.

Process Efficiency and Manufacturing Flexibility

Friction Stir Welding (FSW) offers higher process efficiency in joining aluminum alloys with low energy consumption and minimal distortion, making it ideal for continuous, automated production lines. Electron Beam Welding (EBW) excels in manufacturing flexibility by enabling deep, precise welds in thick materials and dissimilar metals under vacuum conditions, though it requires complex setup and higher operational costs. FSW's solid-state technique ensures faster cycle times and less post-weld treatment, whereas EBW provides unmatched weld quality for aerospace and high-strength steel applications despite longer preparation and alignment requirements.

Defect Formation and Quality Control

Friction Stir Welding (FSW) often encounters defects such as voids, kissing bonds, and surface flashes due to inadequate tool rotation speed or travel speed, requiring precise parameter control for quality assurance. Electron Beam Welding (EBW) can face porosity, cracking, and keyhole instability caused by improper beam focus or vacuum conditions, demanding strict vacuum maintenance and beam parameter optimization for defect minimization. Quality control in FSW leverages real-time temperature monitoring and ultrasonic inspection, while EBW relies on X-ray imaging and metallographic analysis to ensure weld integrity and minimize defect formation.

Applications in Aerospace Structures

Friction Stir Welding (FSW) is widely used in aerospace for joining aluminum alloys in fuselage panels and wing structures due to its solid-state process that minimizes distortion and enhances fatigue resistance. Electron Beam Welding (EBW) excels in aerospace applications requiring deep, precision welds in titanium and nickel-based superalloys, crucial for engine components and structural parts exposed to high temperatures. Both FSW and EBW improve structural integrity and weight efficiency, critical parameters in aerospace manufacturing.

Environmental and Operational Considerations

Friction Stir Welding (FSW) offers significant environmental advantages by operating at lower temperatures, reducing energy consumption and the emission of harmful gases compared to Electron Beam Welding (EBW), which requires high vacuum conditions and significant power input. FSW produces minimal fumes and welding by-products, enhancing workplace safety and reducing the need for extensive ventilation. Operationally, FSW allows for in-situ joining of large components with minimal distortion, whereas EBW demands precise vacuum chambers and is limited to smaller, complex parts due to its stringent environmental requirements.

Future Trends in Aerospace Welding Technologies

Friction Stir Welding (FSW) is advancing with innovations in automation and real-time process monitoring, enhancing its application for lightweight aluminum alloys in aerospace structures to improve joint strength and reduce residual stress. Electron Beam Welding (EBW) continues to evolve through development in vacuum-free technologies and hybrid beam methods, enabling precision joins of high-performance titanium and nickel-based superalloys critical for next-generation jet engines. Future trends indicate a convergence of these welding techniques with additive manufacturing and AI-driven quality control systems to optimize aerospace component fabrication, reduce production time, and improve material performance under extreme service conditions.

Solid-state joining

Friction Stir Welding and Electron Beam Welding are solid-state joining techniques that produce high-strength, defect-free joints by avoiding melting, with Friction Stir Welding using mechanical stirring at low temperatures and Electron Beam Welding employing high-velocity electron beams in a vacuum.

Fusion welding

Friction Stir Welding produces solid-state bonds by mechanically mixing materials without melting, while Electron Beam Welding achieves fusion welding through high-energy electron beams that melt and join metals with deep penetration and minimal distortion.

Heat-affected zone (HAZ)

Friction Stir Welding produces a narrower and more controlled Heat-Affected Zone (HAZ) with minimal thermal distortion compared to Electron Beam Welding, which generates a larger HAZ due to its high energy density and deeper penetration.

Tool shoulder design

Tool shoulder design in Friction Stir Welding significantly influences heat generation and material flow, whereas Electron Beam Welding relies on precise electron beam control without a tool shoulder component.

Vacuum chamber

Electron Beam Welding requires a vacuum chamber to prevent electron scattering and ensure precise weld quality, whereas Friction Stir Welding operates effectively in atmospheric conditions without vacuum.

Stir zone microstructure

Friction Stir Welding produces a refined, equiaxed grain microstructure in the stir zone due to dynamic recrystallization, whereas Electron Beam Welding forms a coarser, columnar grain structure with potential grain growth from localized melting and solidification.

Weld penetration

Friction Stir Welding achieves moderate weld penetration through solid-state deformation, while Electron Beam Welding provides deep, precise penetration by utilizing a concentrated electron beam in a vacuum.

Residual stress

Friction Stir Welding generates lower residual stress and distortion compared to Electron Beam Welding due to its solid-state process and localized heat input.

Aerospace alloy compatibility

Friction Stir Welding exhibits superior compatibility with aerospace aluminum alloys by minimizing distortion and preserving mechanical properties, while Electron Beam Welding excels in joining titanium and high-strength steels with deep penetration and minimal contamination.

Process automation

Friction Stir Welding enables higher process automation through solid-state joining without filler material and minimal post-processing, whereas Electron Beam Welding requires vacuum environments and precise beam control, making automation more complex but suitable for high-precision applications.

Friction Stir Welding vs Electron Beam Welding Infographic

njnir.com

njnir.com