Fly-by-wire systems replace traditional mechanical control with electronic interfaces, enhancing aircraft responsiveness and reducing pilot workload. These systems improve safety by enabling real-time flight data processing and automated adjustments, which mechanical controls cannot achieve. However, mechanical controls provide tactile feedback and fail-safe reliability, making them essential backups in aerospace engineering.

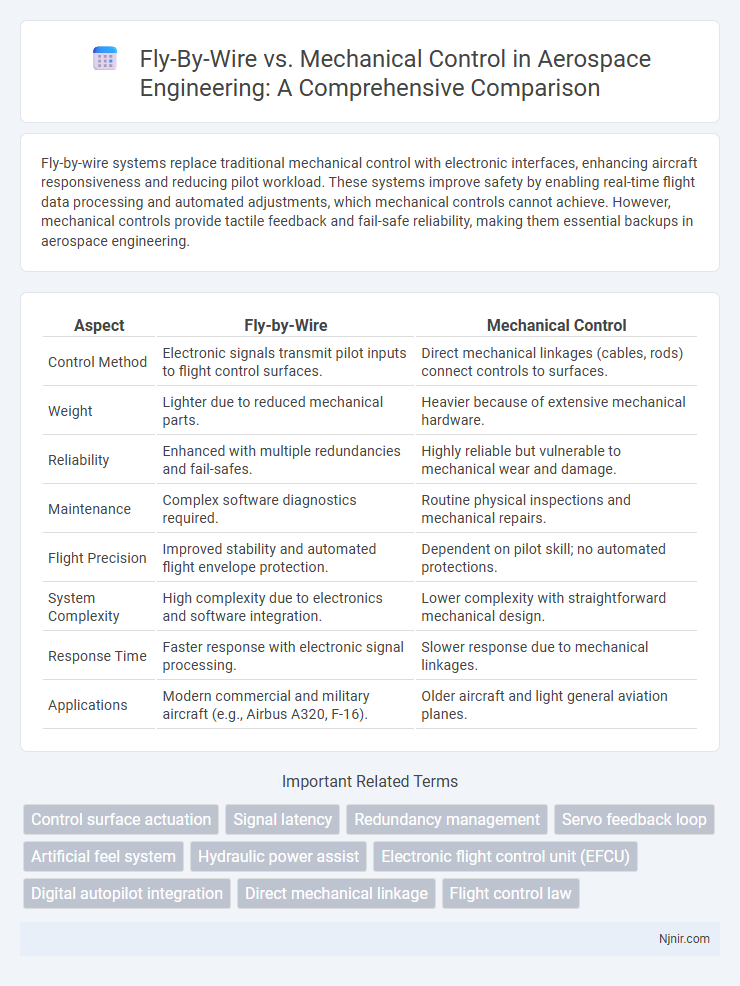

Table of Comparison

| Aspect | Fly-by-Wire | Mechanical Control |

|---|---|---|

| Control Method | Electronic signals transmit pilot inputs to flight control surfaces. | Direct mechanical linkages (cables, rods) connect controls to surfaces. |

| Weight | Lighter due to reduced mechanical parts. | Heavier because of extensive mechanical hardware. |

| Reliability | Enhanced with multiple redundancies and fail-safes. | Highly reliable but vulnerable to mechanical wear and damage. |

| Maintenance | Complex software diagnostics required. | Routine physical inspections and mechanical repairs. |

| Flight Precision | Improved stability and automated flight envelope protection. | Dependent on pilot skill; no automated protections. |

| System Complexity | High complexity due to electronics and software integration. | Lower complexity with straightforward mechanical design. |

| Response Time | Faster response with electronic signal processing. | Slower response due to mechanical linkages. |

| Applications | Modern commercial and military aircraft (e.g., Airbus A320, F-16). | Older aircraft and light general aviation planes. |

Introduction to Aircraft Control Systems

Aircraft control systems consist of mechanisms enabling pilots to maneuver the aircraft through various flight conditions. Fly-by-wire control systems replace traditional mechanical linkages with electronic interfaces, providing enhanced precision, reduced weight, and automated stability features. Mechanical control systems rely on physical cables and rods, offering direct tactile feedback but requiring greater pilot effort and maintenance.

Evolution of Flight Control: From Mechanical to Fly-by-Wire

The evolution of flight control systems transitioned from purely mechanical linkages to advanced fly-by-wire technology, enhancing precision and safety in modern aircraft. Mechanical controls relied on direct physical connections such as cables and pulleys, limiting responsiveness and increasing pilot workload. Fly-by-wire replaces these with electronic signals processed by flight control computers, enabling automated stabilization, reduced weight, and improved handling in complex flight conditions.

Core Principles of Mechanical Flight Controls

Mechanical flight controls operate through direct physical linkages--cables, rods, pulleys--that connect the pilot's input to control surfaces, ensuring tactile feedback and immediate response. These core principles emphasize reliability, simplicity, and maintenance predictability by relying on established mechanical components resistant to electronic failures. Unlike fly-by-wire systems that use electronic signals and computers, mechanical controls offer transparent, analog control where pilot force directly moves control surfaces without intermediary processing.

Fundamentals of Fly-by-Wire Technology

Fly-by-wire technology replaces traditional mechanical control systems with electronic interfaces, transforming pilot inputs into digital signals transmitted to flight control computers. These systems enable precise manipulation of control surfaces by processing sensor data and adjusting control laws, enhancing aircraft stability, safety, and responsiveness. Core components include sensors, processors, actuators, and redundant communication networks to ensure reliability and fault tolerance throughout flight operations.

Key Differences: Mechanical vs Fly-by-Wire Systems

Mechanical control systems rely on direct physical linkages such as cables and rods to transmit pilot inputs to aircraft control surfaces, ensuring tactile feedback and straightforward maintenance but adding weight and susceptibility to wear. Fly-by-wire systems replace mechanical linkages with electronic signals processed by flight control computers, enabling enhanced flight precision, automatic stability adjustments, and reduced aircraft weight while requiring sophisticated software and redundancy for safety. Key differences include the reliance on physical connections in mechanical systems versus electronic signal transmission in fly-by-wire, the level of pilot feedback, system complexity, and overall aircraft performance benefits.

Safety and Reliability Considerations

Fly-by-wire systems enhance safety by incorporating multiple redundant computer systems that detect and correct pilot errors, reducing mechanical failure risks common in traditional mechanical controls. Mechanical control systems rely on direct physical linkages, offering simplicity and reliability through tangible feedback but are more vulnerable to wear and mechanical failure over time. Advanced fly-by-wire technology integrates real-time diagnostics and automated protections, significantly improving aircraft reliability and pilot response under critical conditions.

Performance and Handling Characteristics

Fly-by-wire systems enhance aircraft performance by enabling precise control inputs through electronic signals, reducing pilot workload and allowing for advanced flight envelope protection. Unlike mechanical control systems, which rely on direct physical linkages and can be heavier and less responsive, fly-by-wire offers adaptive handling characteristics that optimize stability and maneuverability under varying flight conditions. This technology also facilitates smoother transitions and reduces the risk of control surface oscillations, improving overall flight safety and pilot confidence.

Maintenance and Operational Costs

Fly-by-wire systems significantly reduce maintenance costs by eliminating mechanical linkages, which are prone to wear and require regular inspection and lubrication. The increased reliability and fault-detection capabilities of fly-by-wire also enhance operational efficiency, lowering downtime and repair expenses compared to traditional mechanical controls. Although initial investment is higher for fly-by-wire, long-term savings in labor, parts replacement, and improved aircraft performance result in overall cost-effectiveness.

Applications in Modern Aircraft

Fly-by-wire systems dominate modern commercial and military aircraft, offering enhanced flight control precision, weight reduction, and automated safety features, such as envelope protection and stability augmentation. Mechanical control systems, once standard in older aircraft models, provide direct pilot input via cables and linkages but lack the flexibility and computational capabilities of fly-by-wire technology. The transition to fly-by-wire enables integration with advanced avionics and autopilots, improving fuel efficiency, handling, and overall flight performance.

Future Trends in Aircraft Control Systems

Fly-by-wire technology is rapidly advancing with integration of artificial intelligence and adaptive control algorithms, enhancing aircraft responsiveness and safety compared to traditional mechanical control systems. Future aircraft control systems emphasize reduced weight, improved fault tolerance, and increased automation, driving a shift away from mechanical linkages toward fully digital, networked flight controls. These innovations enable more precise handling, fuel efficiency, and seamless integration with autonomous flight operations.

Control surface actuation

Fly-by-wire control surface actuation uses electronic signals to operate actuators, enhancing precision and reducing pilot workload, whereas mechanical control relies on direct physical linkages for surface movement, offering simplicity but increased weight and maintenance.

Signal latency

Fly-by-wire control systems significantly reduce signal latency compared to mechanical controls by transmitting electronic signals instantly, enhancing response times and precision in aircraft operations.

Redundancy management

Fly-by-wire systems enhance redundancy management by integrating multiple independent electronic control channels and automatic fault detection, significantly increasing reliability compared to traditional mechanical control systems reliant on physical linkages.

Servo feedback loop

Fly-by-wire systems utilize electronic servo feedback loops for precise, real-time control adjustments, enhancing aircraft stability and responsiveness compared to traditional mechanical control systems reliant on direct physical linkages.

Artificial feel system

The artificial feel system in fly-by-wire controls replicates tactile feedback found in mechanical control systems, enhancing pilot perception and safety by simulating natural aerodynamic forces.

Hydraulic power assist

Fly-by-wire systems enhance aircraft control by using electronic signals and hydraulic power assist, which reduces pilot workload and improves responsiveness compared to traditional mechanical control systems reliant solely on direct hydraulic or manual input.

Electronic flight control unit (EFCU)

The Electronic Flight Control Unit (EFCU) in fly-by-wire systems processes pilot inputs through digital signals to adjust control surfaces precisely, offering superior responsiveness and fault diagnosis compared to traditional mechanical control systems.

Digital autopilot integration

Fly-by-wire systems enable seamless digital autopilot integration by replacing mechanical linkages with electronic controls, enhancing precision and responsiveness.

Direct mechanical linkage

Fly-by-wire systems use electronic signals to control aircraft surfaces, whereas mechanical control relies on a direct mechanical linkage for precise and immediate pilot input transmission.

Flight control law

Flight control laws in fly-by-wire systems use computerized algorithms to enhance aircraft stability and performance, contrasting with the direct mechanical linkages of traditional mechanical controls that rely on pilot input without electronic intervention.

Fly-by-wire vs Mechanical control Infographic

njnir.com

njnir.com