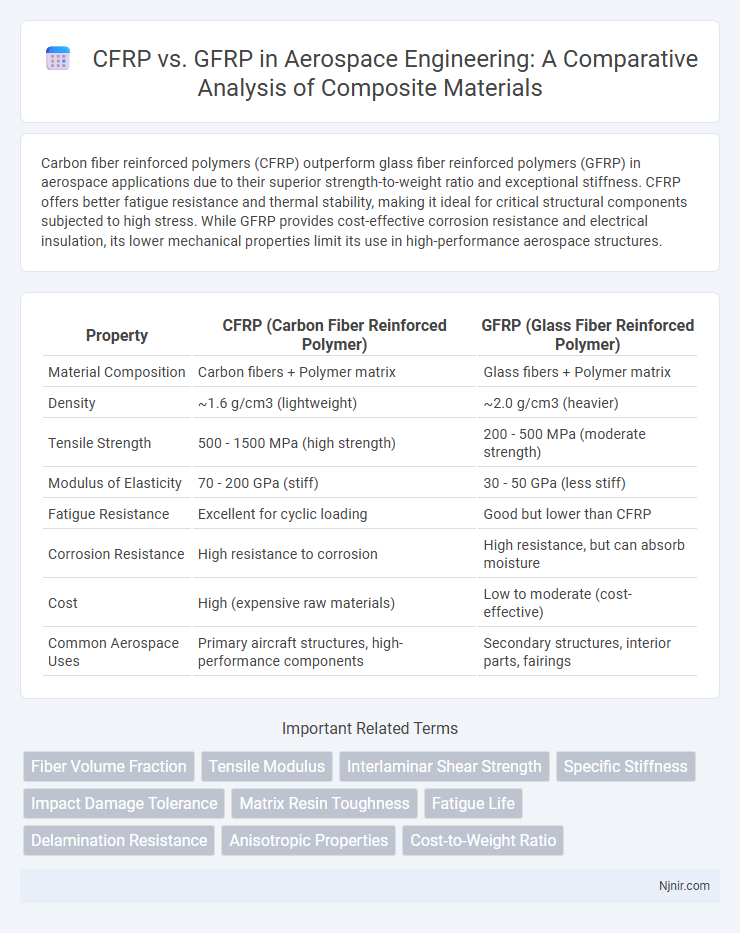

Carbon fiber reinforced polymers (CFRP) outperform glass fiber reinforced polymers (GFRP) in aerospace applications due to their superior strength-to-weight ratio and exceptional stiffness. CFRP offers better fatigue resistance and thermal stability, making it ideal for critical structural components subjected to high stress. While GFRP provides cost-effective corrosion resistance and electrical insulation, its lower mechanical properties limit its use in high-performance aerospace structures.

Table of Comparison

| Property | CFRP (Carbon Fiber Reinforced Polymer) | GFRP (Glass Fiber Reinforced Polymer) |

|---|---|---|

| Material Composition | Carbon fibers + Polymer matrix | Glass fibers + Polymer matrix |

| Density | ~1.6 g/cm3 (lightweight) | ~2.0 g/cm3 (heavier) |

| Tensile Strength | 500 - 1500 MPa (high strength) | 200 - 500 MPa (moderate strength) |

| Modulus of Elasticity | 70 - 200 GPa (stiff) | 30 - 50 GPa (less stiff) |

| Fatigue Resistance | Excellent for cyclic loading | Good but lower than CFRP |

| Corrosion Resistance | High resistance to corrosion | High resistance, but can absorb moisture |

| Cost | High (expensive raw materials) | Low to moderate (cost-effective) |

| Common Aerospace Uses | Primary aircraft structures, high-performance components | Secondary structures, interior parts, fairings |

Introduction to CFRP and GFRP in Aerospace Engineering

Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) are extensively used composite materials in aerospace engineering, prized for their high strength-to-weight ratios and corrosion resistance. CFRP offers superior stiffness and tensile strength due to its carbon fibers, making it ideal for primary structural components in aircraft and spacecraft. GFRP, while less costly and easier to manufacture, provides good impact resistance and electrical insulation, often used in secondary structures and non-critical components.

Material Composition and Manufacturing Processes

Carbon Fiber Reinforced Polymer (CFRP) consists of carbon fibers embedded in a polymer matrix, offering high tensile strength and stiffness with a lightweight profile, primarily manufactured through processes like autoclave curing, resin transfer molding, and filament winding. Glass Fiber Reinforced Polymer (GFRP) incorporates glass fibers within a polymer matrix, providing cost-effective corrosion resistance and moderate strength, typically produced using hand lay-up, spray-up, or pultrusion techniques. The choice between CFRP and GFRP depends on the desired mechanical properties and manufacturing costs, with CFRP favored for high-performance applications and GFRP for economical and corrosion-resistant solutions.

Mechanical Properties: Strength and Stiffness

Carbon Fiber Reinforced Polymer (CFRP) exhibits superior tensile strength and stiffness compared to Glass Fiber Reinforced Polymer (GFRP), with CFRP typically reaching tensile strengths above 6000 MPa and stiffness values around 70-210 GPa. GFRP generally offers tensile strengths in the range of 2000-3500 MPa and stiffness values between 20-40 GPa, making it less rigid and strong but more cost-effective. The higher modulus of elasticity in CFRP enhances load-bearing capacity and resistance to deformation, which is critical in high-performance aerospace and automotive applications.

Weight Considerations and Performance Impact

Carbon Fiber Reinforced Polymer (CFRP) offers a significant weight advantage over Glass Fiber Reinforced Polymer (GFRP), with CFRP densities typically around 1.6 g/cm3 compared to GFRP's 2.0 g/cm3, leading to lighter composite structures ideal for aerospace and automotive applications. The higher stiffness-to-weight ratio of CFRP enhances structural performance by providing greater strength and rigidity without added mass, improving fuel efficiency and load-bearing capacity. While GFRP is cost-effective and corrosion-resistant, its increased weight impacts dynamic performance and energy consumption, making CFRP the preferred choice where minimizing weight and maximizing mechanical performance are critical.

Durability and Environmental Resistance

Carbon Fiber Reinforced Polymer (CFRP) exhibits superior durability and environmental resistance compared to Glass Fiber Reinforced Polymer (GFRP), particularly in high-stress and corrosive environments. CFRP's carbon fibers provide excellent resistance to fatigue, chemical exposure, and temperature fluctuations, enhancing its lifespan in aerospace and automotive applications. In contrast, GFRP, while cost-effective, tends to absorb moisture and degrade more quickly under UV radiation and alkaline conditions, limiting its long-term performance in harsh settings.

Cost Analysis in Aerospace Applications

Carbon Fiber Reinforced Polymer (CFRP) typically exhibits higher initial material costs than Glass Fiber Reinforced Polymer (GFRP) due to the expensive carbon fiber production process. Despite the premium, CFRP's superior strength-to-weight ratio often translates to long-term cost savings in aerospace applications by reducing fuel consumption and maintenance expenses. GFRP remains a cost-effective alternative for non-critical components where lower mechanical properties suffice, balancing performance with budget constraints.

Common Applications of CFRP and GFRP in Aircraft

CFRP (Carbon Fiber Reinforced Polymer) is extensively used in aircraft for primary structures such as fuselage, wings, and tail sections due to its high strength-to-weight ratio and excellent fatigue resistance. GFRP (Glass Fiber Reinforced Polymer) finds common applications in secondary structures, interior panels, fairings, and radomes where cost-effectiveness and corrosion resistance are prioritized over extreme mechanical performance. Both materials contribute to aircraft weight reduction, enhancing fuel efficiency and overall performance in commercial and military aviation.

Repairability and Maintenance Challenges

CFRP (Carbon Fiber Reinforced Polymer) offers higher strength-to-weight ratios but presents significant repairability challenges due to its sensitivity to heat and complex fiber structure, requiring specialized techniques and equipment for effective maintenance. GFRP (Glass Fiber Reinforced Polymer), while less strong, is more forgiving during repairs, allowing for simpler patching processes and better resistance to environmental degradation over time. Maintenance of CFRP often involves higher costs and longer downtime compared to GFRP, making GFRP preferable for applications demanding ease of repair and routine upkeep.

Sustainability and Recycling Concerns

Carbon Fiber Reinforced Polymers (CFRP) offer superior strength-to-weight ratios but pose significant sustainability challenges due to energy-intensive production and limited recyclability. Glass Fiber Reinforced Polymers (GFRP) are more environmentally friendly with easier recycling processes and lower energy consumption during manufacturing, making them preferable for sustainable applications. Both materials require advancements in recycling technology to reduce environmental impact and promote circular economy practices in composite industries.

Future Trends in Composite Materials for Aerospace

Carbon Fiber Reinforced Polymer (CFRP) is increasingly favored in aerospace for its superior strength-to-weight ratio and thermal stability compared to Glass Fiber Reinforced Polymer (GFRP), which remains valued for cost-effectiveness and corrosion resistance. Future trends emphasize hybrid composites combining CFRP and GFRP to optimize mechanical performance and reduce manufacturing costs. Advances in nanomaterial integration and automated fiber placement technologies are expected to further enhance the durability and sustainability of composite materials in aerospace applications.

Fiber Volume Fraction

CFRP typically achieves higher fiber volume fractions of 60-70%, resulting in superior strength and stiffness compared to GFRP, which usually has fiber volume fractions around 40-60%.

Tensile Modulus

CFRP offers a significantly higher tensile modulus, typically around 70-80 GPa, compared to GFRP's tensile modulus of approximately 20-30 GPa, making CFRP more suitable for high-strength, lightweight structural applications.

Interlaminar Shear Strength

CFRP exhibits significantly higher interlaminar shear strength, typically ranging from 70 to 90 MPa, compared to GFRP's 30 to 50 MPa, making CFRP more suitable for high-stress composite applications.

Specific Stiffness

CFRP exhibits a higher specific stiffness of approximately 100-150 GPa/(g/cm3) compared to GFRP's specific stiffness of around 30-50 GPa/(g/cm3), making CFRP more suitable for weight-sensitive structural applications.

Impact Damage Tolerance

Carbon Fiber Reinforced Polymers (CFRP) exhibit significantly higher impact damage tolerance than Glass Fiber Reinforced Polymers (GFRP) due to their superior stiffness, strength, and energy absorption capacity under dynamic loading conditions.

Matrix Resin Toughness

CFRP exhibits higher matrix resin toughness compared to GFRP, resulting in superior impact resistance and durability under mechanical stress.

Fatigue Life

CFRP exhibits significantly higher fatigue life compared to GFRP due to its superior tensile strength and stiffness properties under cyclic loading conditions.

Delamination Resistance

Carbon Fiber Reinforced Polymer (CFRP) exhibits significantly higher delamination resistance compared to Glass Fiber Reinforced Polymer (GFRP) due to its superior interfacial bonding and fiber-matrix adhesion.

Anisotropic Properties

CFRP exhibits higher anisotropic strength and stiffness due to carbon fibers' directional alignment, whereas GFRP shows more isotropic behavior with moderate anisotropy influenced by glass fibers' orientation.

Cost-to-Weight Ratio

CFRP offers a higher cost-to-weight ratio compared to GFRP due to its superior strength and stiffness despite a higher material cost.

CFRP vs GFRP Infographic

njnir.com

njnir.com