Scramjets operate efficiently at hypersonic speeds by allowing supersonic airflow through the engine, whereas ramjets rely on subsonic airflow and are suitable for lower supersonic speeds. Scramjets offer greater fuel efficiency and higher speed potential, making them ideal for applications like spaceplane propulsion and hypersonic cruise missiles. The absence of moving parts in both engines reduces mechanical complexity but requires advanced materials and precise airflow management to withstand extreme temperatures and pressures.

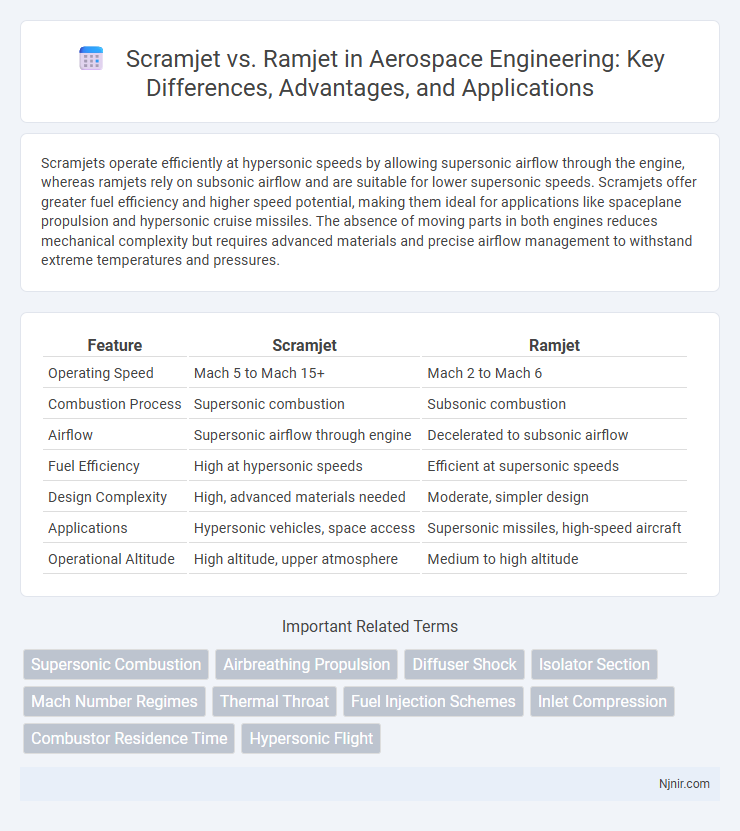

Table of Comparison

| Feature | Scramjet | Ramjet |

|---|---|---|

| Operating Speed | Mach 5 to Mach 15+ | Mach 2 to Mach 6 |

| Combustion Process | Supersonic combustion | Subsonic combustion |

| Airflow | Supersonic airflow through engine | Decelerated to subsonic airflow |

| Fuel Efficiency | High at hypersonic speeds | Efficient at supersonic speeds |

| Design Complexity | High, advanced materials needed | Moderate, simpler design |

| Applications | Hypersonic vehicles, space access | Supersonic missiles, high-speed aircraft |

| Operational Altitude | High altitude, upper atmosphere | Medium to high altitude |

Introduction to Scramjet and Ramjet Technologies

Scramjet and ramjet technologies are both air-breathing jet engines designed for supersonic and hypersonic speeds, relying on high-speed airflow compression without moving parts. Ramjets operate efficiently at speeds between Mach 3 and Mach 6 by decelerating the airflow to subsonic speeds before combustion, while scramjets maintain supersonic airflow throughout the engine, enabling operation beyond Mach 6. These propulsion systems leverage unique combustion dynamics and aerodynamic principles to achieve high-speed thrust for applications in aerospace and defense.

Historical Development of Air-Breathing Engines

The historical development of air-breathing engines highlights the evolution from ramjets, first successfully tested during World War II, to scramjets, which emerged in the late 20th century as a solution for hypersonic flight. Ramjets operate efficiently at supersonic speeds by compressing incoming air without moving parts, while scramjets maintain supersonic airflow through the engine, enabling higher speed capabilities above Mach 5. Key milestones include the 1940s ramjet experiments powering missiles and the 2000s scramjet demonstrations like NASA's X-43, marking significant advancements in aerospace propulsion technology.

Fundamental Operating Principles

Scramjets operate by allowing supersonic airflow to enter the combustion chamber, enabling combustion at hypersonic speeds and eliminating the need for moving parts. Ramjets rely on subsonic airflow compression achieved through the engine's high-speed forward motion, requiring supersonic speeds to function but limiting maximum velocity. Both engines utilize airbreathing propulsion principles but differ fundamentally in how they manage airflow and combustion to optimize performance across various high-speed flight regimes.

Comparative Design and Architecture

Scramjets operate with supersonic airflow through the engine, incorporating a fixed geometry inlet and a combustion chamber designed to sustain stable supersonic combustion, whereas ramjets rely on subsonic combustion with variable geometry for air compression. The scramjet's architecture minimizes pressure losses by avoiding shock-induced slowing of airflow, enhancing efficiency at hypersonic speeds above Mach 5, while ramjets optimize performance between Mach 3 and Mach 6 through shockwave compression and deceleration of airflow to subsonic speeds. Structural materials in scramjets must withstand higher thermal loads due to extreme combustion temperatures, leading to advanced thermal protection systems compared to ramjet designs.

Performance at Various Speed Regimes

Scramjets outperform ramjets at hypersonic speeds above Mach 5 by maintaining supersonic airflow throughout the engine, enabling efficient combustion and thrust generation. Ramjets excel in the supersonic range between Mach 2 and Mach 5 due to their simpler design and effective air compression through subsonic combustion chambers. At lower speeds below Mach 2, neither scramjets nor ramjets are effective, with turbojets or rockets preferred for propulsion.

Fuel Efficiency and Propulsion Effectiveness

Scramjets achieve higher fuel efficiency than ramjets by operating at hypersonic speeds above Mach 5, using supersonic combustion that minimizes thermal losses and maximizes thrust generation. Ramjets, effective from Mach 3 to Mach 6, rely on subsonic combustion that limits fuel efficiency due to longer combustion times and higher drag. The propulsion effectiveness of scramjets surpasses ramjets at extreme speeds, as scramjets maintain stable combustion at supersonic airflow, enabling superior thrust-to-fuel ratios and extended range.

Material Challenges and Thermal Management

Scramjets and ramjets face significant material challenges due to extreme temperatures exceeding 2000degC during hypersonic flight, necessitating advanced high-temperature alloys and ceramic matrix composites (CMCs) for structural integrity. Thermal management in scramjets relies heavily on active cooling techniques like regenerative fuel cooling and heat-resistant thermal barrier coatings to prevent material degradation under shock-induced heating. Ramjets, operating at lower speeds, demand less intensive cooling but still require durable materials with oxidation resistance to withstand sustained combustion chamber temperatures around 1200-1500degC.

Application in Modern Aerospace Missions

Scramjets enable hypersonic speeds above Mach 5, making them ideal for advanced spaceplane and missile systems requiring rapid atmospheric acceleration. Ramjets operate efficiently at supersonic speeds between Mach 3 and 6, commonly used in cruise missiles and high-speed military aircraft for sustained propulsion. Modern aerospace missions leverage scramjets for cost-effective satellite launches and long-range strike capabilities, while ramjets serve tactical roles where consistent supersonic thrust is necessary.

Key Advantages and Limitations

Scramjets offer significantly higher speeds than ramjets due to their supersonic combustion capability, enabling efficient hypersonic travel above Mach 5, while ramjets are optimized for speeds between Mach 3 and Mach 6 but slow down above this range. The key advantage of scramjets lies in their ability to maintain combustion at supersonic airflow, reducing drag and thermal stress, whereas ramjets rely on subsonic combustion that restricts operational speed and efficiency at high velocities. However, scramjets face challenges in ignition and stability at low speeds, requiring rocket-assisted launch systems, while ramjets can operate from lower speeds but suffer from reduced efficiency and increased drag in hypersonic regimes.

Future Trends in Hypersonic Propulsion

Scramjet engines, capable of efficiently operating at hypersonic speeds above Mach 5, are poised to revolutionize future aerospace travel and defense with enhanced fuel efficiency and thrust-to-weight ratios compared to conventional ramjets. Ramjets remain effective up to around Mach 6 but lack the supersonic combustion capability that enables scramjets to sustain higher velocities, making scramjets the preferred choice for next-generation hypersonic vehicles. Research in materials science and computational fluid dynamics continues to accelerate scramjet development, promising breakthroughs in hypersonic propulsion, thermal management, and flight control systems.

Supersonic Combustion

Scramjets achieve efficient supersonic combustion by maintaining supersonic airflow through the engine, unlike ramjets that slow airflow to subsonic speeds, enabling higher speed hypersonic travel.

Airbreathing Propulsion

Scramjets operate efficiently at hypersonic speeds by compressing incoming air supersonically, while ramjets perform optimally at supersonic speeds by decelerating airflow to subsonic speeds for combustion in airbreathing propulsion systems.

Diffuser Shock

Scramjets use oblique shock waves in their diffuser for efficient supersonic combustion at hypersonic speeds, whereas ramjets rely on normal shock waves in their diffuser to decelerate airflow to subsonic speeds before combustion.

Isolator Section

The isolator section in scramjets is designed to maintain supersonic flow by minimizing shock-induced pressure losses, unlike ramjets where the isolator manages subsonic deceleration and pressure stabilization.

Mach Number Regimes

Scramjets operate efficiently at hypersonic speeds above Mach 5 by allowing supersonic airflow through the combustion chamber, whereas ramjets function optimally between Mach 3 and Mach 6 by compressing air subsonically before combustion.

Thermal Throat

The scramjet's thermal throat operates at significantly higher temperatures than the ramjet's due to supersonic airflow, requiring advanced cooling materials and thermal management techniques.

Fuel Injection Schemes

Scramjet fuel injection schemes optimize supersonic airflow mixing using angled struts or cavity-based injectors, whereas ramjet designs rely on subsonic airflow diffusion and conventional shear coaxial or strut-mounted injectors for effective combustion.

Inlet Compression

Scramjets achieve efficient inlet compression at hypersonic speeds by maintaining supersonic airflow throughout the engine, while ramjets rely on shock waves to slow airflow to subsonic speeds for compression.

Combustor Residence Time

Scramjet combustors achieve significantly shorter residence times than ramjets by maintaining supersonic airflow, enabling efficient high-speed combustion at hypersonic velocities.

Hypersonic Flight

Scramjets enable efficient hypersonic flight above Mach 5 by using supersonic combustion, unlike ramjets that operate effectively only up to Mach 5 with subsonic combustion.

Scramjet vs Ramjet Infographic

njnir.com

njnir.com