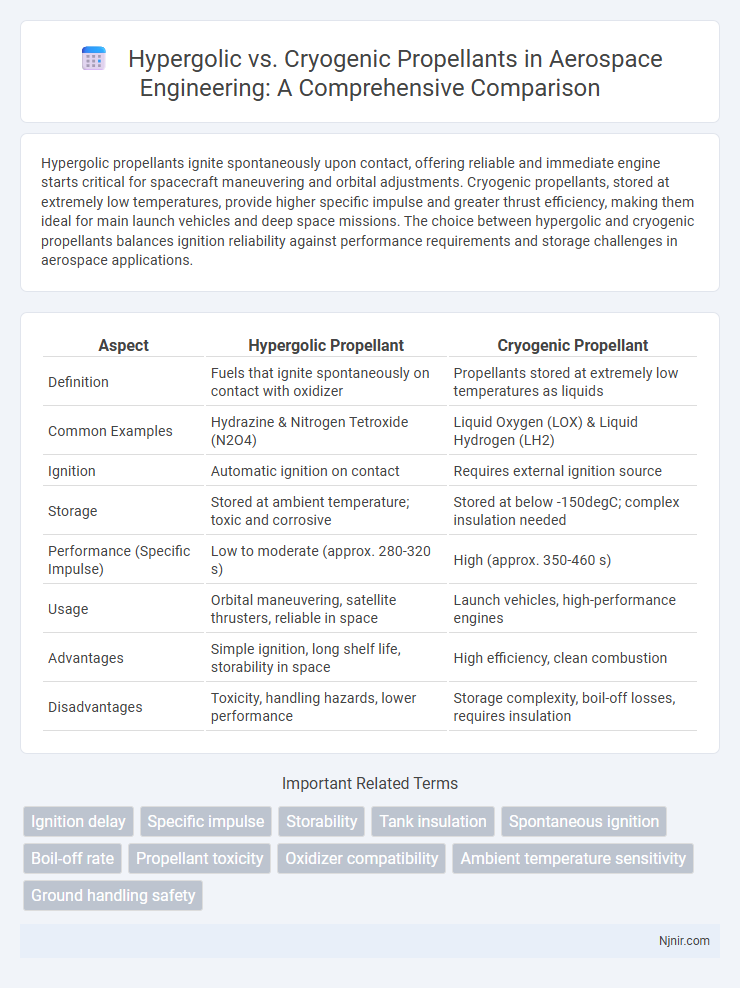

Hypergolic propellants ignite spontaneously upon contact, offering reliable and immediate engine starts critical for spacecraft maneuvering and orbital adjustments. Cryogenic propellants, stored at extremely low temperatures, provide higher specific impulse and greater thrust efficiency, making them ideal for main launch vehicles and deep space missions. The choice between hypergolic and cryogenic propellants balances ignition reliability against performance requirements and storage challenges in aerospace applications.

Table of Comparison

| Aspect | Hypergolic Propellant | Cryogenic Propellant |

|---|---|---|

| Definition | Fuels that ignite spontaneously on contact with oxidizer | Propellants stored at extremely low temperatures as liquids |

| Common Examples | Hydrazine & Nitrogen Tetroxide (N2O4) | Liquid Oxygen (LOX) & Liquid Hydrogen (LH2) |

| Ignition | Automatic ignition on contact | Requires external ignition source |

| Storage | Stored at ambient temperature; toxic and corrosive | Stored at below -150degC; complex insulation needed |

| Performance (Specific Impulse) | Low to moderate (approx. 280-320 s) | High (approx. 350-460 s) |

| Usage | Orbital maneuvering, satellite thrusters, reliable in space | Launch vehicles, high-performance engines |

| Advantages | Simple ignition, long shelf life, storability in space | High efficiency, clean combustion |

| Disadvantages | Toxicity, handling hazards, lower performance | Storage complexity, boil-off losses, requires insulation |

Introduction to Hypergolic and Cryogenic Propellants

Hypergolic propellants ignite spontaneously upon contact, eliminating the need for an external ignition source, making them reliable for spacecraft maneuvering and orbital adjustments. Cryogenic propellants, such as liquid hydrogen and liquid oxygen, are stored at extremely low temperatures to maintain their liquid state and provide high specific impulse for launch vehicles. Understanding the operational characteristics and storage requirements of hypergolic and cryogenic propellants is crucial for propulsion system design and mission planning.

Chemical Composition and Reaction Mechanisms

Hypergolic propellants consist of a fuel and an oxidizer that ignite spontaneously upon contact, typically involving combinations like hydrazine derivatives with nitrogen tetroxide, enabling immediate and reliable ignition without external ignition sources. Cryogenic propellants primarily contain liquefied gases such as liquid hydrogen and liquid oxygen, requiring external ignition systems as these substances do not ignite on contact but combust through controlled mixing and ignition at extremely low temperatures. The chemical reaction mechanisms in hypergolic systems rely on exothermic redox reactions triggered by direct contact, while cryogenic reactions depend on the controlled combustion of supercooled propellants to generate thrust efficiently.

Storage and Handling Requirements

Hypergolic propellants offer simplified storage and handling as they ignite spontaneously upon contact and remain stable at ambient temperatures, reducing the need for complex cooling systems. Cryogenic propellants require ultra-low temperature storage infrastructure to maintain their liquid state, necessitating insulated tanks and continuous refrigeration to prevent boil-off and pressure build-up. Handling cryogenic fuels demands stringent safety protocols due to extreme cold and high volatility, while hypergolic propellants involve managing toxicity and corrosiveness risks.

Ignition Reliability and Safety Concerns

Hypergolic propellants ignite spontaneously upon contact, ensuring highly reliable ignition without the need for an external ignition source, which is critical for precise engine restarts in spacecraft. Cryogenic propellants, such as liquid hydrogen and liquid oxygen, require complex ignition systems and are sensitive to temperature fluctuations, impacting ignition reliability. Safety concerns with hypergolic fuels include their extreme toxicity and corrosiveness, while cryogenic propellants pose risks due to their extremely low temperatures and potential for rapid vaporization and explosion.

Performance Metrics: ISP and Thrust Comparison

Hypergolic propellants offer reliable ignition and storability but generally exhibit lower specific impulse (ISP) in the range of 280-320 seconds compared to cryogenic propellants, which achieve higher ISP values typically between 350-450 seconds due to their higher energy content. Thrust levels generated by cryogenic engines, such as those using liquid hydrogen and liquid oxygen, often surpass hypergolic engines, making them ideal for high-performance launch stages. The trade-off involves hypergolic propellants delivering simpler ignition systems and better long-duration storage, while cryogenic fuels yield superior performance metrics critical for maximizing payload capacity.

Applications in Rocketry and Spacecraft

Hypergolic propellants ignite spontaneously upon contact, making them ideal for spacecraft maneuvering thrusters and satellite attitude control systems due to their reliable ignition and restart capabilities. Cryogenic propellants, such as liquid hydrogen and liquid oxygen, offer high specific impulse and energy density, making them the preferred choice for launch vehicle main engines and deep space missions requiring significant thrust. The selection between hypergolic and cryogenic fuels depends on mission requirements for performance, ignition reliability, and storability in space environments.

Environmental Impact and Byproduct Concerns

Hypergolic propellants, such as hydrazine and nitrogen tetroxide, produce highly toxic and carcinogenic byproducts that pose significant environmental hazards during handling, storage, and combustion. Cryogenic propellants like liquid oxygen and liquid hydrogen generate primarily water vapor as exhaust, resulting in minimal environmental pollution and lower greenhouse gas emissions. The environmental impact of hypergolic fuels is further exacerbated by soil and groundwater contamination risks, whereas cryogenic propellants offer a cleaner, more sustainable alternative despite challenges in storage and cryogenic boil-off.

Cost Analysis and Economic Considerations

Hypergolic propellants offer lower initial costs due to simpler engine designs and easier storage at room temperature, but incur higher long-term expenses owing to their toxicity, handling requirements, and environmental regulations. Cryogenic propellants require substantial investment in insulation, storage infrastructure, and chilled delivery systems, increasing upfront costs, though they provide higher performance and cost efficiency for large-scale or reusable missions. Evaluating economic considerations involves balancing the immediate savings of hypergolic systems against the greater efficiency and reduced operational costs afforded by cryogenic technology over a vehicle's lifecycle.

Recent Innovations and Research Trends

Recent innovations in hypergolic propellants emphasize environmentally friendly, non-toxic formulations to replace traditional toxic substances like hydrazine, improving safety and reducing handling costs. Research trends in cryogenic propellants focus on enhancing storage stability and cryocooling technologies, enabling longer mission durations and improved engine performance with fuels such as liquid hydrogen and oxygen. Advances in additive manufacturing and catalyst development have also optimized ignition reliability and overall propulsion efficiency for both hypergolic and cryogenic systems.

Future Prospects: Toward Next-Generation Propellants

Next-generation propellants aim to combine the storability and ignition reliability of hypergolic fuels with the high performance and low environmental impact of cryogenic propellants. Research into green hypergolic alternatives using less toxic and more efficient compounds is accelerating, promising safer handling and reduced environmental hazards. Advances in cryogenic propellant technologies focus on improving cooling and insulation methods to enable longer-term storage and greater mission flexibility for deep space exploration.

Ignition delay

Hypergolic propellants enable instantaneous ignition upon contact, eliminating ignition delay typical in cryogenic propellants that require external ignition systems.

Specific impulse

Hypergolic propellants typically offer lower specific impulse values around 280-320 seconds compared to cryogenic propellants like liquid hydrogen and liquid oxygen, which achieve higher specific impulse values exceeding 350 seconds.

Storability

Hypergolic propellants offer superior storability due to their stability at ambient temperatures, unlike cryogenic propellants which require constant refrigeration to maintain low temperatures and prevent boil-off.

Tank insulation

Hypergolic propellant tanks require minimal insulation due to stable ambient storage temperatures, whereas cryogenic propellant tanks demand advanced multi-layer insulation to prevent boil-off from ultra-low temperature fuels.

Spontaneous ignition

Hypergolic propellants ignite spontaneously upon contact, eliminating the need for an external ignition source unlike cryogenic propellants which require precise ignition systems due to their non-spontaneous combustion.

Boil-off rate

Hypergolic propellants exhibit negligible boil-off rates compared to cryogenic propellants, which experience significant boil-off due to their low boiling points and storage in cryogenic conditions.

Propellant toxicity

Hypergolic propellants exhibit higher toxicity due to their corrosive and carcinogenic nature, whereas cryogenic propellants are generally less toxic but require complex handling due to extreme low temperatures.

Oxidizer compatibility

Hypergolic propellants use storable and highly reactive oxidizers like nitrogen tetroxide that ignite spontaneously on contact with fuel, while cryogenic propellants rely on liquefied oxygen requiring complex cooling systems to maintain compatibility and prevent phase change.

Ambient temperature sensitivity

Hypergolic propellants ignite spontaneously at ambient temperatures with minimal sensitivity, while cryogenic propellants require stringent temperature control due to their susceptibility to boiling and vaporization.

Ground handling safety

Hypergolic propellants pose higher ground handling safety risks due to their toxicity and spontaneous ignition, whereas cryogenic propellants require stringent temperature control but are generally safer to manage on the ground.

Hypergolic vs Cryogenic Propellant Infographic

njnir.com

njnir.com