Hybrid rockets combine the high performance of liquid propellants with the simplicity and safety of solid fuels, offering improved controllability and throttle capability compared to solid rockets. Solid rockets provide high thrust and structural simplicity but lack flexibility in thrust modulation and restart capability. Hybrid systems enhance mission adaptability by allowing precise control over combustion, making them suitable for variable payload demands in aerospace applications.

Table of Comparison

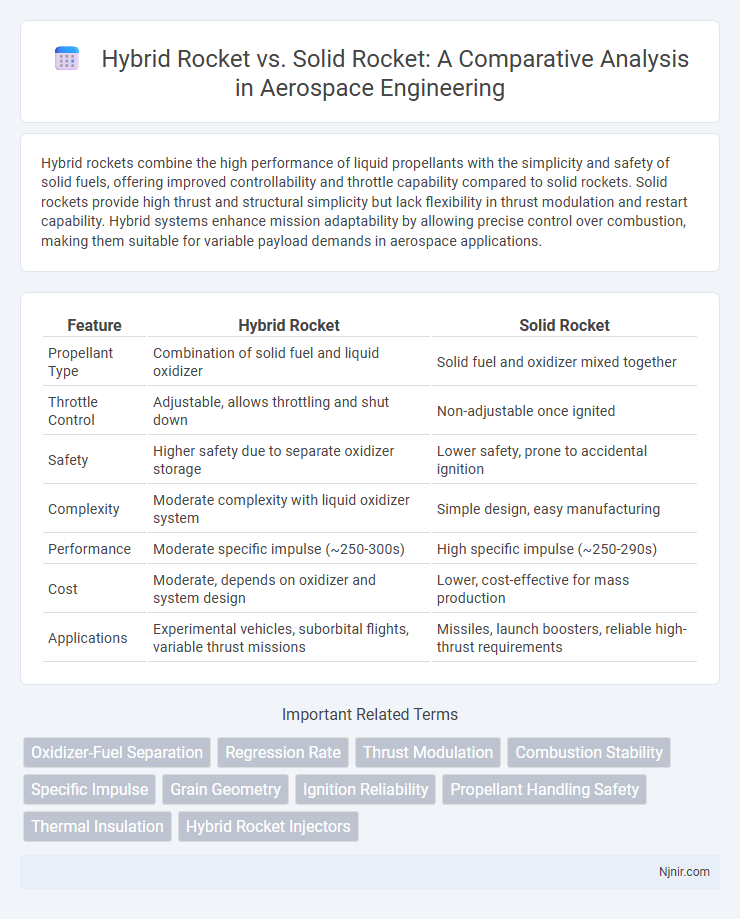

| Feature | Hybrid Rocket | Solid Rocket |

|---|---|---|

| Propellant Type | Combination of solid fuel and liquid oxidizer | Solid fuel and oxidizer mixed together |

| Throttle Control | Adjustable, allows throttling and shut down | Non-adjustable once ignited |

| Safety | Higher safety due to separate oxidizer storage | Lower safety, prone to accidental ignition |

| Complexity | Moderate complexity with liquid oxidizer system | Simple design, easy manufacturing |

| Performance | Moderate specific impulse (~250-300s) | High specific impulse (~250-290s) |

| Cost | Moderate, depends on oxidizer and system design | Lower, cost-effective for mass production |

| Applications | Experimental vehicles, suborbital flights, variable thrust missions | Missiles, launch boosters, reliable high-thrust requirements |

Introduction to Hybrid and Solid Rockets

Hybrid rockets utilize a combination of solid fuel and a liquid or gaseous oxidizer, offering throttle control and improved safety compared to solid rockets that rely solely on a pre-packaged solid propellant. Solid rockets generate thrust by igniting a solid chemical mixture, providing simplicity, reliability, and high thrust-to-weight ratios but lack controllability once ignited. The hybrid design merges the advantages of both, balancing performance flexibility with operational safety.

Fundamental Design Differences

Hybrid rockets combine a liquid oxidizer with a solid fuel, offering throttle control and improved safety compared to solid rockets, which use a pre-mixed solid propellant in a single homogeneous grain. The fundamental design difference lies in the separate phases of the propellant in hybrids, allowing modulation of thrust by varying oxidizer flow, whereas solid rockets rely on fixed combustion rates determined by grain geometry. This separation in hybrids results in simplified fueling logistics and potential for restart capability, contrasting with the inherently simpler but less flexible solid rocket design.

Propellant Composition and Characteristics

Hybrid rockets utilize a combination of solid fuel and a liquid or gaseous oxidizer, enabling controlled combustion and throttling capabilities, whereas solid rockets rely entirely on a pre-mixed solid propellant which limits control once ignited. The hybrid propellant composition allows for safer handling and easier ignition due to the separated oxidizer and fuel phases, contrasting with the homogeneous solid propellant which offers simpler design but produces higher combustion pressures and less flexibility. Solid propellants often contain a mixture of powdered oxidizers like ammonium perchlorate and binders such as hydroxyl-terminated polybutadiene (HTPB), while hybrid systems commonly use solid hydrocarbons or rubber-based fuels combined with liquid oxygen or nitrous oxide oxidizers.

Thrust Control and Modulation

Hybrid rockets offer precise thrust control and modulation due to their ability to regulate the oxidizer flow, enabling adjustable thrust levels during flight for improved mission flexibility. Solid rockets produce fixed thrust profiles once ignited, limiting modulation capabilities and making them less adaptable to varying flight requirements. The thrust control in hybrid rockets enhances safety and efficiency, especially in applications needing variable thrust or abort scenarios.

Safety Considerations and Risks

Hybrid rockets offer enhanced safety compared to solid rockets due to their ability to control the oxidizer flow, reducing the risk of accidental ignition and enabling in-flight shutdown if necessary. Solid rockets, while simpler and more reliable in design, pose higher safety risks because once ignited, they burn uncontrollably and cannot be easily extinguished or throttled. The reduced handling risks and abort capabilities make hybrids a preferable option for missions prioritizing safety and risk management.

Performance Efficiency and Specific Impulse

Hybrid rockets offer higher performance efficiency compared to solid rockets due to their controllable thrust and better fuel mixture optimization. Specific impulse (Isp) for hybrid rockets typically ranges between 250 to 350 seconds, surpassing the average 180 to 300 seconds of solid rockets. The variable oxidizer flow in hybrids enables more precise combustion control, enhancing overall propulsion efficiency and mission adaptability.

Manufacturing and Cost Analysis

Hybrid rockets offer a simpler manufacturing process compared to solid rockets, as their fuel and oxidizer components are stored separately and combined during operation, reducing complexity and facilitating safer handling. Solid rockets require precise casting and curing of propellant mixtures, which involves specialized equipment and stringent quality control, often leading to higher production costs. Cost analysis reveals that hybrids can be more economical for small to medium-scale applications due to lower material waste and easier scalability, whereas solid rockets tend to be cost-effective for mass production but incur higher initial tooling expenses.

Environmental Impact and Emissions

Hybrid rockets produce fewer emissions compared to solid rockets due to their combination of a liquid oxidizer and a solid fuel, allowing for more controlled combustion and reduced release of hazardous pollutants. Solid rockets emit higher levels of particulates and toxic compounds such as aluminum oxide and hydrochloric acid, contributing to atmospheric pollution and ozone layer depletion. The cleaner combustion process of hybrid rockets results in lower environmental impact, making them a more sustainable choice for space missions.

Applications in Aerospace Missions

Hybrid rockets offer precise thrust control and throttle capabilities, making them ideal for suborbital flights, experimental missions, and reusable launch systems in aerospace. Solid rockets deliver high thrust and simplicity, favored for booster stages in launch vehicles, military missiles, and emergency escape systems due to their reliability and storability. Both propulsion types play crucial roles in mission design, with hybrids suited for variable performance needs and solids for robust, high-thrust applications.

Future Developments and Innovations

Future developments in hybrid rockets emphasize advanced fuel formulations and improved oxidizer delivery systems to enhance thrust control and efficiency, potentially bridging the gap between the simplicity of solid rockets and the controllability of liquid engines. Innovations in solid rocket technology focus on environmentally friendly propellants and additive manufacturing techniques, aiming to increase performance while reducing production costs and environmental impact. Both propulsion types benefit from advancements in materials science and computational fluid dynamics, driving improvements in reliability, scalability, and mission adaptability for next-generation space exploration.

Oxidizer-Fuel Separation

Hybrid rockets use separate solid fuel and liquid oxidizer tanks allowing precise oxidizer-fuel separation for controlled combustion, whereas solid rockets combine both in a single solid grain limiting this separation and combustion control.

Regression Rate

Hybrid rockets exhibit a variable regression rate influenced by oxidizer flow and grain composition, typically lower and more controllable than the fixed, higher regression rate of solid rockets.

Thrust Modulation

Hybrid rockets offer superior thrust modulation compared to solid rockets by enabling real-time control of propellant flow, enhancing mission flexibility and performance precision.

Combustion Stability

Hybrid rockets exhibit enhanced combustion stability compared to solid rockets due to the controlled regression rate of the liquid oxidizer and solid fuel interface, reducing pressure fluctuations and ensuring consistent thrust.

Specific Impulse

Hybrid rockets typically achieve higher specific impulse than solid rockets due to their efficient combination of liquid oxidizers and solid fuels.

Grain Geometry

Hybrid rockets utilize adjustable grain geometry to optimize thrust and burn rate, whereas solid rockets have fixed grain geometry that limits performance flexibility.

Ignition Reliability

Hybrid rockets offer higher ignition reliability than solid rockets due to their controlled fuel flow and restart capability, reducing the risk of ignition failure during launch.

Propellant Handling Safety

Hybrid rockets offer enhanced propellant handling safety by using a combination of a solid fuel and a liquid or gaseous oxidizer, reducing the risk of accidental ignition compared to solid rockets, which contain fully pre-mixed, highly reactive propellants.

Thermal Insulation

Hybrid rockets require advanced thermal insulation materials to protect liquid fuel systems from intense combustion heat, while solid rockets utilize inherently heat-resistant casing materials that simplify thermal management.

Hybrid Rocket Injectors

Hybrid rocket injectors enhance thrust control and combustion efficiency by precisely regulating fuel and oxidizer flow compared to fixed-flow solid rocket motors.

Hybrid Rocket vs Solid Rocket Infographic

njnir.com

njnir.com