Ablative shielding absorbs intense heat through material erosion, making it ideal for single-use reentry vehicles where protection is critical during brief exposure. Reusable shielding employs durable materials and advanced heat-resistant composites designed to withstand multiple reentries without significant degradation. Selecting between ablative and reusable shielding depends on mission objectives, cost efficiency, and the need for vehicle longevity in aerospace engineering.

Table of Comparison

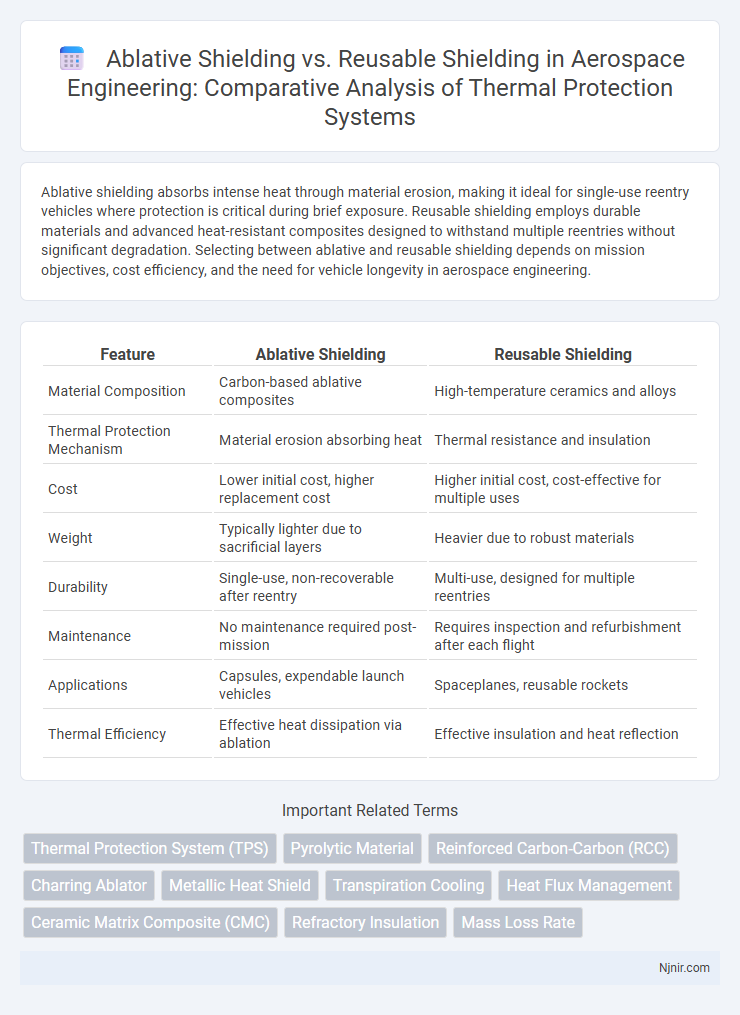

| Feature | Ablative Shielding | Reusable Shielding |

|---|---|---|

| Material Composition | Carbon-based ablative composites | High-temperature ceramics and alloys |

| Thermal Protection Mechanism | Material erosion absorbing heat | Thermal resistance and insulation |

| Cost | Lower initial cost, higher replacement cost | Higher initial cost, cost-effective for multiple uses |

| Weight | Typically lighter due to sacrificial layers | Heavier due to robust materials |

| Durability | Single-use, non-recoverable after reentry | Multi-use, designed for multiple reentries |

| Maintenance | No maintenance required post-mission | Requires inspection and refurbishment after each flight |

| Applications | Capsules, expendable launch vehicles | Spaceplanes, reusable rockets |

| Thermal Efficiency | Effective heat dissipation via ablation | Effective insulation and heat reflection |

Introduction to Thermal Protection Systems in Aerospace Engineering

Ablative shielding in thermal protection systems (TPS) offers efficient heat absorption by sacrificial material erosion during re-entry, preventing structural damage to spacecraft. Reusable shielding relies on durable materials like reinforced carbon-carbon or ceramic tiles that withstand multiple thermal cycles without significant degradation. Evaluating ablative versus reusable shielding materials is crucial for optimizing aerospace designs based on mission duration, cost, and thermal load requirements.

Fundamentals of Ablative Shielding

Ablative shielding relies on the controlled erosion of a material that absorbs and dissipates intense heat during atmospheric re-entry by sublimating or charring, effectively protecting the spacecraft from thermal damage. Reusable shielding, in contrast, uses materials designed to withstand repeated thermal cycles without significant degradation, often employing high-temperature ceramics or reinforced carbon composites. The fundamental advantage of ablative shielding lies in its efficient heat absorption through material ablation, making it ideal for single-use missions with extreme heat loads.

Principles of Reusable Shielding

Reusable shielding relies on high-temperature resistant materials such as reinforced carbon-carbon and ceramic tiles that absorb and dissipate heat without significant erosion, enabling multiple reentries. The principle involves thermal protection through insulation and radiant cooling rather than material consumption, maintaining structural integrity over repeated missions. This approach reduces maintenance costs and turnaround time compared to ablative shielding, which sacrifices material during each reentry to protect the spacecraft.

Comparative Materials Science: Ablative vs. Reusable Shields

Ablative shielding employs materials like phenolic resins and carbon composites that absorb and dissipate heat by gradually eroding during reentry, providing effective short-term thermal protection. Reusable shielding utilizes durable ceramics and reinforced carbon-carbon composites engineered to withstand extreme temperatures without significant material loss, enabling multiple missions. Comparative materials science highlights the trade-off between mass and durability, with ablative shields offering lightweight, sacrificial protection and reusable shields focusing on long-term structural integrity and thermal resistance.

Performance Metrics and Heat Load Management

Ablative shielding excels in high heat load management by absorbing and dissipating intense thermal energy through material sacrifice, making it ideal for single-use reentry vehicles with peak temperatures exceeding 3000degC. Reusable shielding employs advanced ceramics or composites that provide durable thermal protection with minimal degradation, enabling multiple missions while maintaining structural integrity under sustained heat loads around 1000degC to 1500degC. Performance metrics indicate ablative shields prioritize maximum heat absorption capacity, whereas reusable shields focus on thermal resistance and mechanical durability for cost-effective reusability.

Cost-Benefit Analysis in Shielding Technologies

Ablative shielding offers lower initial costs due to simpler materials and designs but involves higher long-term expenses from single-use replacement after each mission. Reusable shielding, though featuring higher upfront investment for advanced heat-resistant materials and enhanced durability, yields cost savings across multiple missions by reducing refurbishment and replacement needs. Cost-benefit analysis weighs the trade-off between the disposable nature of ablative systems and the lifecycle efficiency of reusable shielding, influencing spacecraft design decisions based on mission duration, frequency, and budget constraints.

Maintenance and Lifecycle Considerations

Ablative shielding requires replacement after each exposure due to sacrificial material erosion, leading to higher maintenance frequency and limited lifecycle. Reusable shielding involves materials designed to withstand multiple thermal cycles without significant degradation, reducing maintenance demands and extending overall service life. Lifecycle considerations favor reusable shielding in applications where long-term durability and cost-effectiveness outweigh the initial complexity of maintenance protocols.

Application Cases: Missions Utilizing Ablative Shielding

Missions utilizing ablative shielding include NASA's Mars rovers, the Apollo lunar landings, and the Stardust comet sample return, where intense heat from atmospheric entry necessitates material erosion to dissipate thermal energy. Ablative heat shields are preferred for high-speed entry scenarios involving substantial convective and radiative heating, such as Mars Science Laboratory and Galileo probe missions. In contrast, reusable shielding systems, like those used on the Space Shuttle, are optimized for lower heat loads and multiple reentries, emphasizing durability over material consumption.

Application Cases: Missions Utilizing Reusable Shielding

Reusable shielding has been employed in missions such as the Space Shuttle program and the Mars Perseverance Rover landing, where thermal protection systems withstand multiple re-entries or intense atmospheric entry events. These missions benefit from reusable shields' ability to reduce cost and turnaround time by allowing refurbishment and repeated use without compromising safety. In contrast, ablative shielding is primarily used in single-use applications like the Apollo lunar module or expendable launch vehicles, where the shield sacrificially erodes to dissipate heat during one-time atmospheric entry.

Future Trends in Thermal Protection System Design

Future trends in thermal protection system (TPS) design emphasize the shift from traditional ablative shielding to advanced reusable shielding materials, enhancing spacecraft longevity and mission flexibility. Innovations in ultra-high-temperature ceramics and composite materials enable reusable shields to withstand extreme reentry conditions while reducing maintenance and refurbishment costs. Integration of real-time health monitoring sensors within reusable TPS offers predictive diagnostics, optimizing safety and performance for future space missions.

Thermal Protection System (TPS)

Ablative shielding in Thermal Protection Systems (TPS) offers one-time, high-efficiency heat absorption by material erosion, while reusable shielding provides durable, multi-mission thermal resistance with materials like reinforced carbon-carbon or ceramic tiles.

Pyrolytic Material

Pyrolytic ablative shielding offers superior thermal protection by sacrificially charring and insulating during re-entry, whereas reusable shielding relies on durable materials like reinforced carbon-carbon to withstand multiple thermal cycles without degradation.

Reinforced Carbon-Carbon (RCC)

Reinforced Carbon-Carbon (RCC) provides superior thermal protection in reusable spacecraft shielding due to its high-temperature resistance and structural integrity compared to single-use ablative materials.

Charring Ablator

Charring ablators in ablative shielding provide superior thermal protection by forming a protective char layer that absorbs heat and ablates away, unlike reusable shielding which relies on insulation materials designed to withstand heat without material loss.

Metallic Heat Shield

Metallic heat shields offer superior reusable shielding capabilities compared to ablative shielding by providing durable thermal protection through high-temperature metal alloys that withstand multiple reentries without erosion.

Transpiration Cooling

Transpiration cooling enhances reusable shielding by continuously releasing coolant through a porous surface to protect against extreme heat, unlike ablative shielding which relies on material erosion for thermal protection.

Heat Flux Management

Ablative shielding efficiently manages high heat flux by absorbing and decomposing heat through material erosion, while reusable shielding controls heat flux via high-reflectivity coatings and thermal insulation to enable multiple reentries.

Ceramic Matrix Composite (CMC)

Ceramic Matrix Composite (CMC) reusable shielding offers superior thermal resistance and durability compared to ablative shielding, enabling multiple high-temperature uses without material degradation.

Refractory Insulation

Refractory insulation in reusable shielding offers superior thermal stability and long-term durability compared to the single-use, sacrificial nature of ablative shielding materials.

Mass Loss Rate

Ablative shielding typically exhibits a higher mass loss rate compared to reusable shielding due to the sacrificial material erosion during thermal protection.

ablative shielding vs reusable shielding Infographic

njnir.com

njnir.com