Hypergolic propellants ignite spontaneously upon contact, offering reliable and immediate ignition crucial for spacecraft maneuvering and orbital adjustments. Cryogenic propellants, stored at extremely low temperatures, provide higher specific impulse and greater efficiency for launch vehicles but require complex thermal management systems. The choice between hypergolic and cryogenic fuels balances ignition reliability against performance efficiency in aerospace propulsion systems.

Table of Comparison

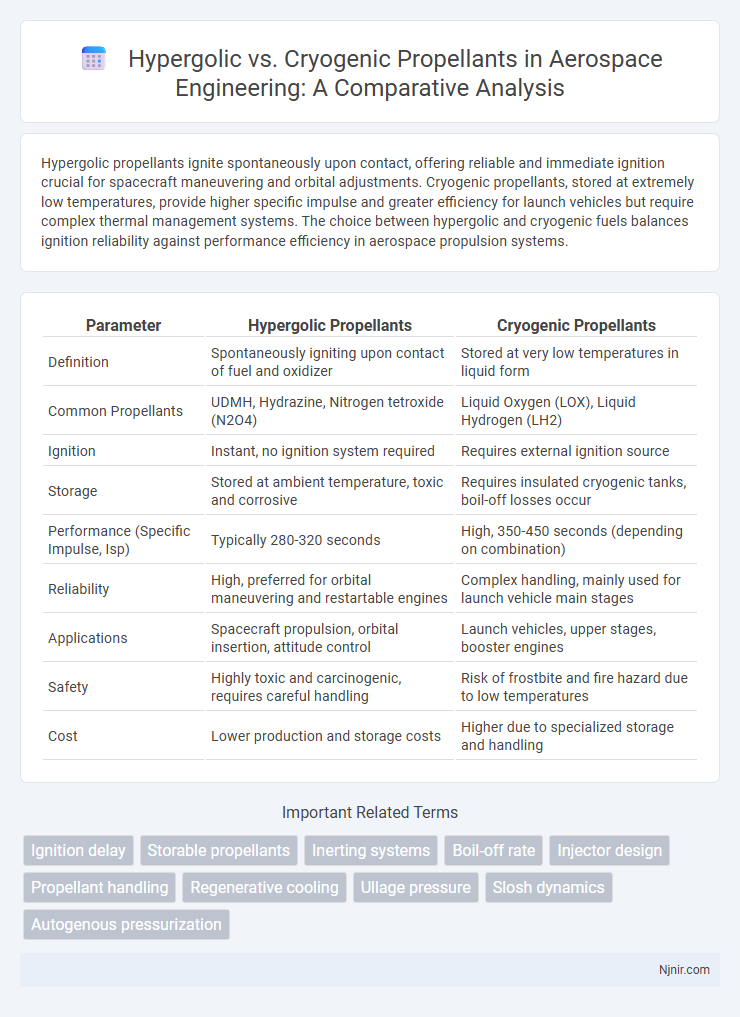

| Parameter | Hypergolic Propellants | Cryogenic Propellants |

|---|---|---|

| Definition | Spontaneously igniting upon contact of fuel and oxidizer | Stored at very low temperatures in liquid form |

| Common Propellants | UDMH, Hydrazine, Nitrogen tetroxide (N2O4) | Liquid Oxygen (LOX), Liquid Hydrogen (LH2) |

| Ignition | Instant, no ignition system required | Requires external ignition source |

| Storage | Stored at ambient temperature, toxic and corrosive | Requires insulated cryogenic tanks, boil-off losses occur |

| Performance (Specific Impulse, Isp) | Typically 280-320 seconds | High, 350-450 seconds (depending on combination) |

| Reliability | High, preferred for orbital maneuvering and restartable engines | Complex handling, mainly used for launch vehicle main stages |

| Applications | Spacecraft propulsion, orbital insertion, attitude control | Launch vehicles, upper stages, booster engines |

| Safety | Highly toxic and carcinogenic, requires careful handling | Risk of frostbite and fire hazard due to low temperatures |

| Cost | Lower production and storage costs | Higher due to specialized storage and handling |

Introduction to Hypergolic and Cryogenic Propellants

Hypergolic propellants ignite instantly upon contact between fuel and oxidizer, enabling reliable engine starts without external ignition systems and are commonly used in spacecraft maneuvering thrusters. Cryogenic propellants, such as liquid hydrogen and liquid oxygen, are stored at extremely low temperatures to maintain their liquid state, offering high specific impulse suitable for launch vehicles and long-duration missions. The choice between hypergolic and cryogenic propellants depends on mission requirements, with hypergolic systems favoring simplicity and storability, while cryogenic systems emphasize performance efficiency.

Chemical Principles: Hypergolic vs Cryogenic Fuels

Hypergolic fuels ignite spontaneously upon contact between the fuel and oxidizer, relying on fast exothermic chemical reactions driven by highly reactive compounds such as hydrazine and nitrogen tetroxide. Cryogenic fuels, including liquid hydrogen and liquid oxygen, require extremely low temperatures to remain in liquid form, enabling high density and specific impulse through combustion but necessitating complex insulation and handling systems. The fundamental chemical principle distinguishing hypergolic from cryogenic propulsion lies in ignition mechanism--spontaneous chemical reactivity versus cryogenically maintained combustion readiness.

Ignition Mechanisms and Reliability

Hypergolic propellants ignite spontaneously upon contact between the fuel and oxidizer, ensuring immediate and reliable ignition without external ignition sources, which enhances mission safety and reduces ignition failure risks. Cryogenic propellants require an external ignition system, such as spark plugs or pyrophoric substances, leading to potential ignition delays and higher complexity in engine start sequences. The inherent ignition reliability of hypergolic systems makes them preferable for critical spacecraft maneuvers, while cryogenic systems offer better performance at the cost of more complex and potentially less reliable ignition mechanisms.

Propellant Storage and Handling Challenges

Hypergolic propellants, such as hydrazine and nitrogen tetroxide, offer storability at ambient temperature, enabling long-term storage and simplified handling without the need for complex refrigeration systems. Cryogenic propellants like liquid oxygen and liquid hydrogen require storage at extremely low temperatures, demanding advanced insulation, temperature control, and pressurization systems to prevent boil-off and maintain performance. The handling of hypergolic fuels poses toxicity and corrosion risks, necessitating stringent safety protocols, while cryogenic fuels present challenges with thermal contraction and material brittleness during fueling operations.

Performance Metrics: Thrust, Efficiency, and ISP

Hypergolic propellants generate reliable ignition instantly upon contact, providing consistent thrust levels suitable for spacecraft maneuvering, though their specific impulse (ISP) typically ranges between 280-330 seconds. Cryogenic propellants, like liquid hydrogen and liquid oxygen, achieve higher performance with ISPs exceeding 350 seconds and deliver greater thrust due to higher energy density and combustion temperature. Efficiency in cryogenic engines is superior due to higher combustion chamber pressures and optimized thermodynamic cycles, making them ideal for heavy-lift launch vehicles despite storage complexity.

Safety Concerns and Risk Assessment

Hypergolic propellants ignite spontaneously upon contact, presenting significant handling risks due to their toxicity and corrosiveness, necessitating stringent safety protocols and specialized equipment to prevent accidental ignition and exposure. Cryogenic propellants, stored at extremely low temperatures, pose hazards such as frostbite, material brittleness, and potential explosive pressure buildup from rapid vaporization, requiring robust insulation and pressure relief systems. Risk assessments for hypergolic systems emphasize chemical toxicity and immediate ignition dangers, while cryogenic systems focus on thermal management and structural integrity under cryogenic conditions.

Applications in Spacecraft and Launch Vehicles

Hypergolic propellants, such as hydrazine and nitrogen tetroxide, are widely used in spacecraft maneuvering thrusters and orbital insertion engines due to their reliable ignition upon contact, enabling precise control in space environments. Cryogenic propellants like liquid hydrogen and liquid oxygen provide high specific impulse and are primarily employed in launch vehicle main engines for Earth-to-orbit thrust, supporting heavy payload delivery. The choice between hypergolic and cryogenic systems depends on mission requirements, with hypergolic preferred for in-space reliability and cryogenic favored for maximizing launch performance.

Cost Analysis: Production and Operational Expenses

Hypergolic propellants, such as hydrazine and nitrogen tetroxide, typically incur higher production costs due to their toxic and corrosive nature requiring specialized handling and storage equipment. Operational expenses for hypergolic systems include extensive safety protocols and disposal procedures, increasing overall mission costs despite their reliability and storability. Cryogenic propellants like liquid hydrogen and liquid oxygen demand expensive insulation and refrigeration infrastructure to maintain low temperatures, driving up both initial production and ongoing operational expenditures.

Environmental Impact and Propellant Toxicity

Hypergolic propellants, such as hydrazine and nitrogen tetroxide, pose significant environmental risks due to their high toxicity and carcinogenic properties, often requiring special handling and disposal protocols to prevent soil and water contamination. Cryogenic propellants like liquid oxygen and liquid hydrogen are generally cleaner, producing water vapor as the primary combustion product, which minimizes harmful emissions and reduces long-term environmental impact. The lower toxicity and cleaner combustion of cryogenic fuels contribute to increased safety for personnel and reduced ecological hazards compared to hypergolic propellants.

Future Trends and Technological Innovations

Future trends in space propulsion emphasize the shift from hypergolic to cryogenic fuels due to cryogenics' higher specific impulse and reduced environmental hazards. Innovations in advanced cryogenic propellant management, such as zero-boil-off storage and cryocooler technology, enhance long-duration mission viability and efficiency. Emerging hybrid systems integrating the reliability of hypergolic ignition with cryogenic performance are being developed to optimize thrust and sustainability in next-generation launch vehicles.

Ignition delay

Hypergolic propellants ignite immediately upon contact, eliminating ignition delay, while cryogenic propellants require precise ignition systems due to inherent ignition delays caused by low temperatures.

Storable propellants

Storable hypergolic propellants ignite spontaneously at ambient temperatures, enabling simpler engine designs and long-term storage, whereas cryogenic propellants require insulating tanks and refrigeration to maintain low temperatures, complicating storage and handling.

Inerting systems

Inerting systems for hypergolic propellants prioritize rapid, moisture-resistant nitrogen purging to prevent spontaneous ignition, whereas cryogenic propellant inerting requires continuous inert gas flow to manage oxygen-rich environments and prevent condensation-related hazards.

Boil-off rate

Hypergolic propellants exhibit negligible boil-off rates compared to cryogenic fuels, which experience significant boil-off due to their extremely low storage temperatures.

Injector design

Hypergolic propellant injectors require precise material compatibility and corrosion resistance due to spontaneous ignition, while cryogenic injectors demand advanced thermal management and insulation to handle extremely low temperatures for stable propellant flow.

Propellant handling

Hypergolic propellants enable immediate ignition upon contact with simpler handling requirements and low-temperature resistance, while cryogenic propellants demand complex insulation and continuous refrigeration to prevent boil-off during storage and transfer.

Regenerative cooling

Hypergolic engines benefit from simpler regenerative cooling due to lower combustion temperatures, while cryogenic engines require advanced regenerative cooling systems to manage extremely high thermal loads from liquid hydrogen and oxygen combustion.

Ullage pressure

Hypergolic propellants maintain ullage pressure through self-pressurizing properties, while cryogenic systems rely on external pressurization to prevent propellant settling and ensure stable engine ignition.

Slosh dynamics

Hypergolic propellants exhibit more predictable slosh dynamics due to stable ignition and consistent fluid properties, whereas cryogenic propellants present complex slosh behavior caused by low-temperature fluid phase changes and variable density gradients.

Autogenous pressurization

Autogenous pressurization in hypergolic engines uses propellant vapor from the tank to pressurize itself, enhancing reliability and simplicity compared to cryogenic engines that often require external pressurant systems.

Hypergolic vs Cryogenic Infographic

njnir.com

njnir.com