Distributed propulsion systems offer enhanced aerodynamic efficiency and noise reduction compared to conventional propulsion by integrating multiple smaller engines across the airframe. This technology enables improved thrust distribution and redundancy, leading to increased performance and safety in aerospace applications. By leveraging electric or hybrid-electric powertrains, distributed propulsion facilitates innovative aircraft designs with reduced environmental impact and greater operational flexibility.

Table of Comparison

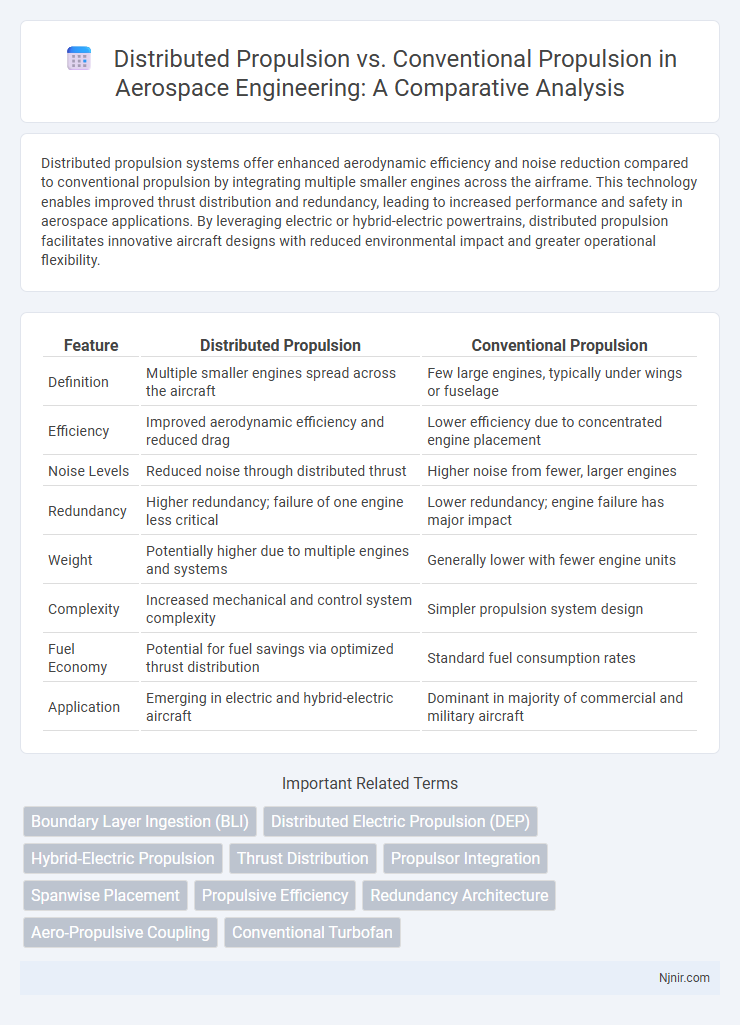

| Feature | Distributed Propulsion | Conventional Propulsion |

|---|---|---|

| Definition | Multiple smaller engines spread across the aircraft | Few large engines, typically under wings or fuselage |

| Efficiency | Improved aerodynamic efficiency and reduced drag | Lower efficiency due to concentrated engine placement |

| Noise Levels | Reduced noise through distributed thrust | Higher noise from fewer, larger engines |

| Redundancy | Higher redundancy; failure of one engine less critical | Lower redundancy; engine failure has major impact |

| Weight | Potentially higher due to multiple engines and systems | Generally lower with fewer engine units |

| Complexity | Increased mechanical and control system complexity | Simpler propulsion system design |

| Fuel Economy | Potential for fuel savings via optimized thrust distribution | Standard fuel consumption rates |

| Application | Emerging in electric and hybrid-electric aircraft | Dominant in majority of commercial and military aircraft |

Introduction to Propulsion in Aerospace Engineering

Distributed propulsion systems integrate multiple smaller engines across the airframe, enhancing aerodynamic efficiency and reducing fuel consumption compared to conventional propulsion, which relies on fewer, larger engines. These systems improve thrust distribution, noise reduction, and offer increased redundancy, supporting advanced aerodynamic designs in aerospace engineering. Conventional propulsion remains dominant due to its established technology and simpler mechanical integration, but distributed propulsion is gaining traction for its potential to advance aircraft performance and environmental sustainability.

Fundamentals of Distributed Propulsion Systems

Distributed propulsion systems utilize multiple smaller engines or motors spread across the aircraft, enhancing aerodynamic efficiency by optimizing lift and thrust distribution. Conventional propulsion relies on fewer, larger engines typically mounted on wings or fuselage, limiting flexibility in thrust control and integration. Fundamental advantages of distributed propulsion include improved fuel efficiency, reduced noise, and enhanced maneuverability through precise thrust vectoring.

Conventional Propulsion: Types and Applications

Conventional propulsion systems primarily include internal combustion engines, gas turbines, and turbojets, widely used in automotive, aviation, and marine industries due to their proven efficiency and power output. Internal combustion engines dominate ground vehicles with variations like diesel and gasoline engines, while gas turbines and turbojets are prevalent in commercial and military aircraft for high-speed and long-distance travel. These propulsion types are favored for their established infrastructure, reliability, and performance under varied operational conditions.

Key Advantages of Distributed Propulsion

Distributed propulsion systems offer enhanced aerodynamic efficiency by strategically placing multiple smaller engines across the airframe, resulting in improved lift-to-drag ratios and reduced fuel consumption. These systems provide greater redundancy and reliability compared to conventional propulsion, as the failure of one engine has less impact on overall performance. Additionally, distributed propulsion enables improved noise reduction and more flexible aircraft designs, supporting advanced concepts such as electric and hybrid-electric aviation.

Limitations and Challenges of Distributed Propulsion

Distributed propulsion systems face limitations such as increased mechanical complexity and higher initial development costs compared to conventional propulsion, which rely on a centralized engine. Challenges include managing thermal loads and ensuring adequate cooling due to multiple smaller engines or motors distributed across the airframe. Integrating distributed propulsion with existing aircraft structures also presents aerodynamic optimization difficulties and necessitates advanced control systems for coordinated thrust management.

Comparative Efficiency: Distributed vs Conventional

Distributed propulsion systems enhance efficiency by optimizing thrust distribution across multiple smaller engines, reducing drag and improving aerodynamic performance compared to conventional propulsion which relies on fewer, larger engines. By enabling precise control and redundancy, distributed propulsion minimizes energy loss and increases fuel efficiency in various flight regimes. Conventional propulsion often faces limitations in thrust modulation and integration with airframe design, resulting in less operational flexibility and higher fuel consumption.

Impact on Aircraft Design and Aerodynamics

Distributed propulsion reshapes aircraft design by integrating multiple small engines along the wingspan, enabling improved lift distribution and reduced wing loading compared to conventional propulsion with a few large engines. This configuration enhances aerodynamic efficiency through boundary layer ingestion and thrust vectoring, resulting in lower drag and increased fuel efficiency. Conventional propulsion systems, typically mounted under the wings or on the fuselage, limit aerodynamic optimization due to concentrated thrust points, leading to less flexibility in wing design and higher induced drag.

Noise and Environmental Considerations

Distributed propulsion systems significantly reduce noise pollution by spreading thrust sources across multiple smaller engines, lowering peak noise levels compared to conventional propulsion systems with larger, centralized engines. This noise reduction benefits urban environments and communities near airports by decreasing the impact of takeoff and landing noise. Environmentally, distributed propulsion enhances fuel efficiency and lowers emissions through optimized thrust distribution and improved aerodynamic integration, contributing to reduced carbon footprints relative to traditional propulsion configurations.

Current Research and Emerging Technologies

Current research in distributed propulsion emphasizes integrating multiple smaller engines across the airframe to enhance aerodynamic efficiency, reduce fuel consumption, and lower emissions compared to conventional propulsion systems. Emerging technologies include electrically driven propulsors and hybrid-electric configurations that enable improved thrust vectoring and noise reduction, critical for urban air mobility and regional aircraft. Advanced materials and control algorithms are being developed to optimize the interaction between distributed propulsion units and airframe dynamics, paving the way for next-generation sustainable aviation solutions.

Future Trends in Aircraft Propulsion Systems

Distributed propulsion systems enhance aircraft efficiency by integrating multiple smaller engines distributed across the airframe, improving thrust distribution and reducing drag compared to conventional propulsion designs relying on few large engines. Future trends emphasize electric and hybrid-electric distributed propulsion technologies to significantly lower emissions and noise while increasing overall aircraft performance. Advancements in materials, battery energy density, and power electronics are accelerating the adoption of distributed propulsion for regional and urban air mobility aircraft, marking a transformative shift in propulsion system architecture.

Boundary Layer Ingestion (BLI)

Boundary Layer Ingestion (BLI) in distributed propulsion systems reduces aircraft drag by ingesting slower-moving boundary layer air into multiple smaller engines, enhancing fuel efficiency compared to conventional propulsion.

Distributed Electric Propulsion (DEP)

Distributed Electric Propulsion (DEP) improves aerodynamic efficiency and reduces emissions by integrating multiple electric motors across an aircraft wing, contrasting with conventional propulsion systems that rely on fewer, centralized engines.

Hybrid-Electric Propulsion

Hybrid-electric propulsion systems enhance distributed propulsion efficiency by combining electric motors with conventional engines to reduce fuel consumption and emissions while improving aircraft performance.

Thrust Distribution

Distributed propulsion enhances thrust distribution efficiency by deploying multiple smaller engines across the airframe, resulting in improved maneuverability and reduced aerodynamic losses compared to conventional propulsion systems with centralized engines.

Propulsor Integration

Distributed propulsion enhances propulsor integration by enabling optimized airflow management, reduced aerodynamic interference, and improved thrust distribution compared to conventional propulsion systems.

Spanwise Placement

Distributed propulsion enhances aerodynamic efficiency by optimally placing multiple smaller engines spanwise along the wing, reducing wing loading and increasing lift compared to conventional propulsion systems with centralized engine placement.

Propulsive Efficiency

Distributed propulsion enhances propulsive efficiency by optimizing thrust distribution across multiple smaller engines, reducing drag and improving fuel consumption compared to conventional single-engine systems.

Redundancy Architecture

Distributed propulsion enhances redundancy architecture by using multiple smaller engines, increasing fault tolerance and system reliability compared to conventional propulsion's single or few large engines.

Aero-Propulsive Coupling

Distributed propulsion enables enhanced aero-propulsive coupling by integrating multiple smaller thrusters across the airframe, improving airflow control and overall propulsion efficiency compared to conventional propulsion systems with centralized engines.

Conventional Turbofan

Conventional turbofan engines produce thrust through a large central fan powered by a gas turbine, offering high efficiency and reliability but limited integration flexibility compared to distributed propulsion systems.

distributed propulsion vs conventional propulsion Infographic

njnir.com

njnir.com