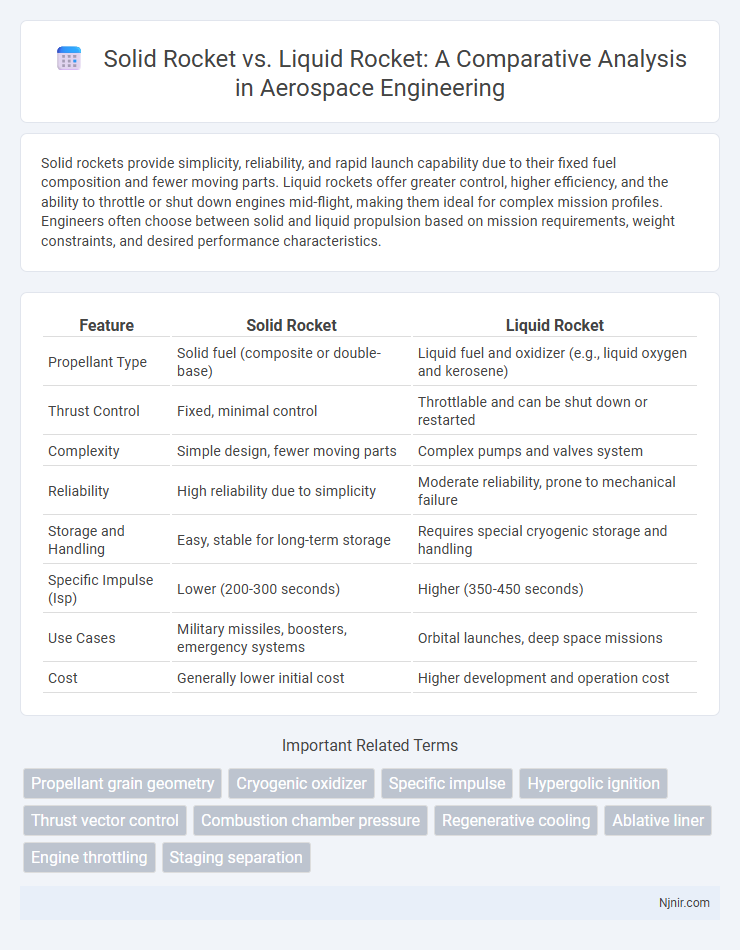

Solid rockets provide simplicity, reliability, and rapid launch capability due to their fixed fuel composition and fewer moving parts. Liquid rockets offer greater control, higher efficiency, and the ability to throttle or shut down engines mid-flight, making them ideal for complex mission profiles. Engineers often choose between solid and liquid propulsion based on mission requirements, weight constraints, and desired performance characteristics.

Table of Comparison

| Feature | Solid Rocket | Liquid Rocket |

|---|---|---|

| Propellant Type | Solid fuel (composite or double-base) | Liquid fuel and oxidizer (e.g., liquid oxygen and kerosene) |

| Thrust Control | Fixed, minimal control | Throttlable and can be shut down or restarted |

| Complexity | Simple design, fewer moving parts | Complex pumps and valves system |

| Reliability | High reliability due to simplicity | Moderate reliability, prone to mechanical failure |

| Storage and Handling | Easy, stable for long-term storage | Requires special cryogenic storage and handling |

| Specific Impulse (Isp) | Lower (200-300 seconds) | Higher (350-450 seconds) |

| Use Cases | Military missiles, boosters, emergency systems | Orbital launches, deep space missions |

| Cost | Generally lower initial cost | Higher development and operation cost |

Introduction to Solid and Liquid Rockets

Solid rockets use a pre-mixed, solid propellant that provides consistent thrust and simpler design, ideal for military applications and initial launch stages. Liquid rockets rely on separate fuel and oxidizer stored in tanks, allowing precise thrust control and higher efficiency, commonly used in space exploration and orbital launch vehicles. Each propulsion type offers unique advantages based on mission requirements, such as thrust variability in liquid rockets versus compactness and reliability in solid rockets.

Design Principles of Solid Rockets

Solid rockets utilize a simple design principle where the propellant is cast or molded into a solid grain inside the combustion chamber, ensuring consistent and stable burn rates. Their compact, self-contained structure eliminates complex fuel pumps and valves, enhancing reliability and ease of storage. The solid propellant composition, often a mixture of powdered oxidizer and fuel bound by a polymer binder, is engineered to optimize thrust and burn duration for specific mission profiles.

Design Principles of Liquid Rockets

Liquid rocket design principles emphasize precise control of propellant flow through turbopumps and valves, enabling adjustable thrust and efficient combustion. The complexity of regeneratively cooled combustion chambers requires advanced materials and engineering to manage high temperatures and pressure. Compared to solid rockets, liquid engines offer greater flexibility in throttleability and restart capability, supporting diverse mission profiles.

Propellant Types and Characteristics

Solid rockets utilize a homogeneous mixture of fuel and oxidizer bound in a solid matrix, offering simplicity and high reliability but limited throttle control and restart capability. Liquid rockets employ separate liquid fuel and oxidizer tanks, enabling precise thrust modulation, engine shutdown, and multiple restarts, though their complexity requires intricate plumbing and cryogenic handling. Propellant types for solid rockets often include ammonium perchlorate composite propellant (APCP), while liquid rockets commonly use combinations such as liquid oxygen (LOX) with RP-1 kerosene or liquid hydrogen for higher efficiency and specific impulse.

Thrust Generation Mechanisms

Solid rockets generate thrust through the combustion of a pre-mixed solid propellant that burns from the inside out, producing high-pressure gas expelled through a nozzle to create thrust. Liquid rockets use separate liquid fuel and oxidizer stored in tanks, which are injected into a combustion chamber where they mix and ignite to produce controlled, sustained thrust. The ability to regulate the flow rates in liquid rockets allows for adjustable thrust levels, unlike solid rockets that offer fixed thrust once ignited.

Performance and Efficiency Comparison

Solid rockets offer simpler design and higher reliability but exhibit lower specific impulse, typically around 250-300 seconds, which limits their efficiency and performance compared to liquid rockets. Liquid rockets achieve higher specific impulse values ranging from 350 to 450 seconds, enabling better fuel efficiency and thrust control during flight. The superior performance of liquid rockets makes them preferable for missions requiring precise maneuvering and longer burn times.

Applications in Aerospace Engineering

Solid rockets are primarily used for military missiles and booster stages due to their simplicity, reliability, and rapid response capability, making them ideal for launch vehicles requiring high thrust at liftoff. Liquid rockets provide greater control over thrust and specific impulse, allowing precise maneuvering and efficiency, which suits orbital insertion and deep-space missions in aerospace engineering. The choice between solid and liquid propulsion depends on mission requirements, with solids favored for quick deployment and liquids preferred for adjustable thrust and long-duration flights.

Safety Considerations and Risks

Solid rockets offer higher stability due to their simpler design and fewer moving parts, reducing the likelihood of leaks or catastrophic failures. Liquid rockets enable greater control with throttling and shutdown capabilities but present risks from highly reactive propellants and complex plumbing systems prone to leaks and explosions. Safety protocols for liquid rockets are more stringent due to the handling of corrosive and cryogenic fluids, while solid rockets require careful manufacturing to prevent cracks that could cause uneven burning or explosions.

Cost and Manufacturing Differences

Solid rockets generally offer lower manufacturing costs due to simpler design and fewer moving parts, making them more cost-effective for short-term projects or military applications. Liquid rockets involve complex components such as pumps and valves, resulting in higher production expenses but allowing for greater control and efficiency during flight. The cost disparity is influenced by the materials used and the required precision of assembly, with solids being easier to produce in large quantities and liquids demanding specialized labor and technology.

Future Trends in Rocket Propulsion

Future trends in rocket propulsion emphasize advancements in hybrid systems that combine the high thrust-to-weight ratio of solid rockets with the controllability of liquid rockets. Innovations in additive manufacturing and green propellants aim to enhance efficiency and reduce environmental impact in both solid and liquid engines. Emerging technologies such as electric pump-fed liquid engines and advanced composite materials are expected to revolutionize cost-effectiveness and reusability in space launch vehicles.

Propellant grain geometry

Solid rocket propellant grain geometry is fixed and shapes thrust profile through core design, while liquid rocket propellant flow is controlled dynamically, allowing adjustable thrust and performance.

Cryogenic oxidizer

Cryogenic oxidizers in liquid rockets, such as liquid oxygen, enable higher specific impulse and greater performance compared to the fixed, less efficient oxidizers used in solid rockets.

Specific impulse

Liquid rockets typically achieve higher specific impulse than solid rockets due to more efficient combustion and adjustable thrust.

Hypergolic ignition

Hypergolic ignition in liquid rockets offers immediate, reliable engine start without external ignition systems, whereas solid rockets rely on pre-installed igniters that do not support hypergolic reactions.

Thrust vector control

Solid rockets use movable nozzles or jet vanes for thrust vector control, while liquid rockets employ gimbaled engines or differential throttling to achieve precise directional control.

Combustion chamber pressure

Solid rocket combustion chambers typically operate at lower pressures around 3-7 MPa, while liquid rocket engines achieve higher combustion chamber pressures exceeding 20 MPa, enabling greater efficiency and thrust control.

Regenerative cooling

Liquid rockets utilize regenerative cooling by circulating propellant around the combustion chamber to prevent overheating, whereas solid rockets lack this system and rely on insulating materials for thermal protection.

Ablative liner

Solid rocket motors use ablative liners to insulate and protect the casing from intense heat during combustion, while liquid rocket engines typically rely on regenerative cooling methods rather than ablative materials.

Engine throttling

Liquid rocket engines offer precise throttling control for variable thrust, whereas solid rocket engines lack throttling capability and operate at a fixed thrust level.

Staging separation

Solid rockets offer simpler, more reliable staging separation due to fewer moving parts, while liquid rockets provide precise control and efficiency during multi-stage separation through complex valve systems.

Solid rocket vs Liquid rocket Infographic

njnir.com

njnir.com