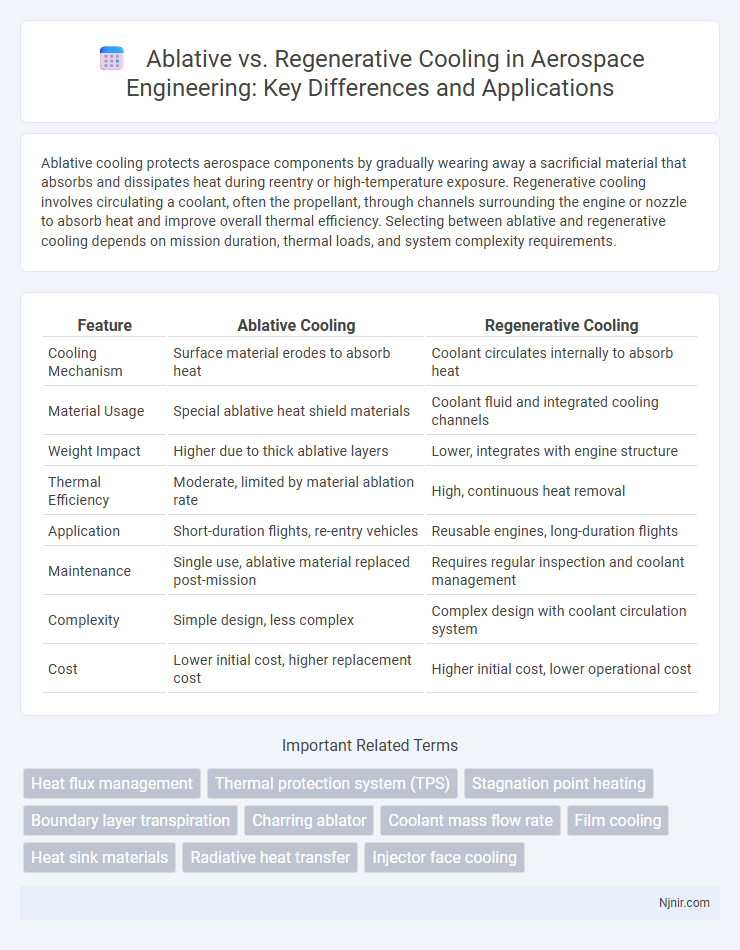

Ablative cooling protects aerospace components by gradually wearing away a sacrificial material that absorbs and dissipates heat during reentry or high-temperature exposure. Regenerative cooling involves circulating a coolant, often the propellant, through channels surrounding the engine or nozzle to absorb heat and improve overall thermal efficiency. Selecting between ablative and regenerative cooling depends on mission duration, thermal loads, and system complexity requirements.

Table of Comparison

| Feature | Ablative Cooling | Regenerative Cooling |

|---|---|---|

| Cooling Mechanism | Surface material erodes to absorb heat | Coolant circulates internally to absorb heat |

| Material Usage | Special ablative heat shield materials | Coolant fluid and integrated cooling channels |

| Weight Impact | Higher due to thick ablative layers | Lower, integrates with engine structure |

| Thermal Efficiency | Moderate, limited by material ablation rate | High, continuous heat removal |

| Application | Short-duration flights, re-entry vehicles | Reusable engines, long-duration flights |

| Maintenance | Single use, ablative material replaced post-mission | Requires regular inspection and coolant management |

| Complexity | Simple design, less complex | Complex design with coolant circulation system |

| Cost | Lower initial cost, higher replacement cost | Higher initial cost, lower operational cost |

Introduction to Rocket Engine Cooling Techniques

Ablative cooling involves the controlled erosion of a sacrificial material lining the combustion chamber, absorbing heat through phase change and material recession to protect engine components. Regenerative cooling circulates cryogenic propellants through cooling channels around the combustion chamber, transferring heat from the chamber walls to the propellant before injection, enhancing thermal management and propellant conditioning. Both techniques are critical in managing the extreme thermal loads of rocket engines, influencing engine efficiency and durability.

Fundamentals of Ablative Cooling

Ablative cooling involves the controlled erosion of a material's surface to absorb and dissipate intense heat, protecting engine components during high-temperature operations. This process relies on the sublimation, pyrolysis, and melting of ablative materials, which transfer thermal energy away from the structure by consuming latent heat through material decomposition. Unlike regenerative cooling, which circulates coolant to absorb heat, ablative cooling permanently sacrifices the outer layer to maintain thermal protection in extreme environments such as rocket nozzles and reentry vehicles.

Principles of Regenerative Cooling

Regenerative cooling involves circulating a coolant through channels or tubes around the combustion chamber and nozzle to absorb heat, which preheats the coolant before it enters the engine, improving thermal efficiency. This method uses materials with high heat capacity and thermal conductivity to manage extreme temperatures in rocket engines. Unlike ablative cooling, which relies on sacrificial layers to absorb and dissipate heat through material erosion, regenerative cooling continuously recycles the coolant, allowing sustained engine operation and performance.

Material Selection for Ablative and Regenerative Systems

Material selection for ablative cooling prioritizes high-temperature resistant composites and polymers that char and erode to absorb and dissipate heat, such as carbon-phenolic and silica-based materials. Regenerative cooling relies on metals with excellent thermal conductivity and corrosion resistance like copper alloys or stainless steel, enabling effective heat exchange through coolant channels. These differences in material properties directly impact the durability and efficiency of thermal management in propulsion systems.

Comparative Thermal Performance

Ablative cooling relies on the gradual erosion of a sacrificial material to absorb and dissipate extreme heat, making it effective for short-duration, high-heat events. Regenerative cooling circulates a coolant--often the propellant--through channels around the combustion chamber, enabling sustained heat transfer and higher thermal efficiency over extended operational periods. Compared to ablative cooling, regenerative cooling offers superior thermal performance by maintaining structural integrity and optimizing engine longevity under continuous high-temperature conditions.

Design Considerations and Engineering Challenges

Ablative cooling relies on a sacrificial material that absorbs heat through controlled erosion, demanding precise material selection and thickness to balance thermal protection and mass constraints. Regenerative cooling circulates propellant through channels in the engine walls, requiring complex channel design, high-pressure resilience, and efficient heat transfer to prevent hot spots and structural fatigue. Both methods pose challenges in maintaining mechanical integrity under thermal stress while optimizing engine performance and weight.

Cost Analysis and Manufacturing Complexity

Ablative cooling involves sacrificial materials that erode during heat exposure, resulting in higher ongoing replacement costs but simpler initial manufacturing processes. Regenerative cooling features coolant channels integrated within the structure, leading to increased manufacturing complexity and upfront expenses due to precision engineering and advanced materials. Cost analysis shows ablative systems are cost-effective for short-duration missions, while regenerative cooling is more economical long-term for reusable engines despite its complex fabrication requirements.

Operational Lifespan and Maintenance Implications

Ablative cooling relies on the gradual erosion of a sacrificial material to protect engine components, offering a limited operational lifespan due to material consumption and requiring frequent replacement after each use. Regenerative cooling circulates propellant through channels around the engine, providing continuous thermal protection that extends operational lifespan and reduces maintenance demands. The sustained cooling efficiency of regenerative systems results in improved engine durability and operational readiness with less downtime compared to ablative systems.

Applications in Modern Aerospace Propulsion

Ablative cooling is extensively employed in solid rocket motors and heat shields where sacrificial materials absorb and carry away intense thermal energy through controlled erosion, ensuring structural integrity during peak thermal loads. Regenerative cooling is predominantly utilized in liquid rocket engines by circulating cryogenic propellants through channels surrounding the combustion chamber and nozzle, effectively transferring heat and enhancing engine efficiency. These cooling methods are critical in modern aerospace propulsion systems to manage extreme temperatures, extend component life, and optimize performance in applications like upper-stage and booster engines.

Future Trends in Engine Cooling Technologies

Ablative cooling, relying on material erosion to dissipate heat, is gradually being supplemented by regenerative cooling, which circulates fuel through cooling channels to absorb engine heat more efficiently. Future trends emphasize hybrid cooling systems combining ablative materials with regenerative pathways to enhance thermal management and engine longevity in high-performance aerospace applications. Advances in additive manufacturing and heat-resistant composites are driving the development of next-generation cooling architectures that optimize fuel consumption and reduce weight.

Heat flux management

Regenerative cooling manages extremely high heat fluxes by circulating coolant through channels to absorb and dissipate heat, whereas ablative cooling controls heat flux by sacrificing material that gradually erodes to protect underlying structures.

Thermal protection system (TPS)

Ablative cooling in thermal protection systems absorbs and dissipates heat through material erosion, while regenerative cooling circulates coolant to actively remove heat and protect spacecraft surfaces during re-entry.

Stagnation point heating

Stagnation point heating in ablative cooling involves controlled material erosion to absorb heat, while regenerative cooling utilizes circulating coolant to efficiently dissipate heat and protect engine surfaces.

Boundary layer transpiration

Boundary layer transpiration enhances ablative cooling by expelling pyrolysis gases to protect surfaces, whereas regenerative cooling relies on circulating coolant fluids to absorb heat without gas layer formation.

Charring ablator

Charring ablators in ablative cooling protect rocket engines by forming a protective carbonaceous char layer that insulates and gradually erodes, contrasting with regenerative cooling which circulates coolant through engine walls to absorb heat.

Coolant mass flow rate

Regenerative cooling requires a lower coolant mass flow rate than ablative cooling due to its continuous heat absorption and heat transfer efficiency.

Film cooling

Film cooling creates a protective layer of coolant along the surface, enhancing thermal resistance more effectively than ablative or regenerative cooling methods in high-temperature gas turbine applications.

Heat sink materials

Ablative cooling uses sacrificial heat sink materials like phenolic resins that char and erode to dissipate heat, whereas regenerative cooling employs durable heat sink materials such as copper or nickel alloy channels through which coolant circulates to absorb and remove heat efficiently.

Radiative heat transfer

Regenerative cooling leverages continuous fluid circulation to absorb heat and reduce radiative heat transfer, whereas ablative cooling relies on material erosion to dissipate heat through sacrificial layers.

Injector face cooling

Injector face cooling in ablative systems relies on sacrificial material erosion to absorb heat, whereas regenerative cooling circulates coolant through channels to remove heat efficiently.

Ablative vs Regenerative cooling Infographic

njnir.com

njnir.com