Deployable structures in aerospace engineering offer compact storage and efficient deployment in space, reducing launch costs and enabling large-scale configurations. Rigid structures provide enhanced stability and strength but often require larger payload volumes and complex assembly processes. Balancing the benefits of deployable flexibility with the robustness of rigid frameworks is crucial for optimizing spacecraft design and mission performance.

Table of Comparison

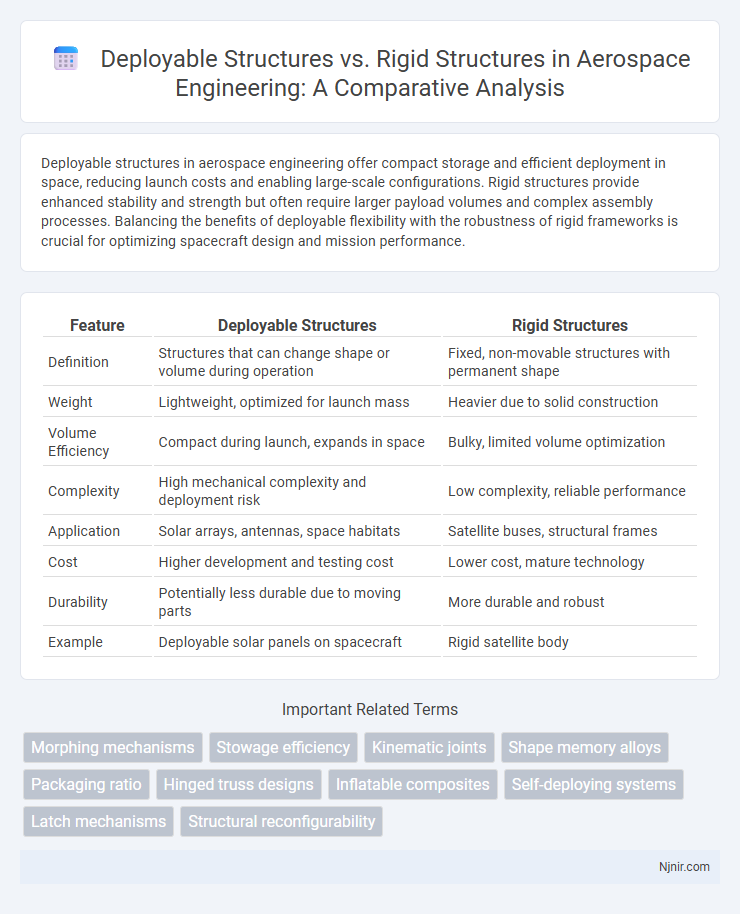

| Feature | Deployable Structures | Rigid Structures |

|---|---|---|

| Definition | Structures that can change shape or volume during operation | Fixed, non-movable structures with permanent shape |

| Weight | Lightweight, optimized for launch mass | Heavier due to solid construction |

| Volume Efficiency | Compact during launch, expands in space | Bulky, limited volume optimization |

| Complexity | High mechanical complexity and deployment risk | Low complexity, reliable performance |

| Application | Solar arrays, antennas, space habitats | Satellite buses, structural frames |

| Cost | Higher development and testing cost | Lower cost, mature technology |

| Durability | Potentially less durable due to moving parts | More durable and robust |

| Example | Deployable solar panels on spacecraft | Rigid satellite body |

Introduction to Structural Types in Aerospace Engineering

Deployable structures in aerospace engineering are designed to transform from a compact state to a functional configuration, optimizing space utilization for launch and expanding post-deployment to perform tasks such as solar arrays or antennas. Rigid structures maintain a fixed geometry, providing high strength and stability critical for carrying aerodynamic loads and housing sensitive instruments in aircraft and spacecraft. The choice between deployable and rigid structures hinges on mission requirements, with deployable structures favoring adaptability and volume efficiency, while rigid structures emphasize structural integrity and load-bearing capacity.

Defining Deployable Structures

Deployable structures are engineered to transform from a compact, stowed configuration into an expanded functional form, enabling efficient transport and rapid assembly. Unlike rigid structures with fixed shapes, deployable systems use mechanisms such as hinges, telescoping elements, or folding joints to achieve adaptability and scalability in applications like aerospace, emergency shelters, and temporary installations. These structures optimize space utilization and operational flexibility while maintaining structural integrity during deployment.

Characteristics of Rigid Structures

Rigid structures exhibit high stiffness and resistance to deformation under load, maintaining their shape without significant bending or flexing. Commonly constructed from materials like steel, concrete, and timber, these structures provide stability and durability in buildings, bridges, and industrial frameworks. Their fixed configurations offer robustness but limit adaptability compared to deployable structures designed for mobility and reconfiguration.

Material Selection: Deployable vs Rigid

Material selection for deployable structures prioritizes lightweight, flexible composites and advanced polymers like carbon fiber-reinforced plastics to enable easy folding, unfolding, and repeated movements without fatigue. Rigid structures rely predominantly on high-strength metals such as steel and aluminum alloys, chosen for their durability, load-bearing capacity, and resistance to deformation under static and dynamic loads. The contrasting material demands reflect the fundamental functional requirements: deployability necessitates adaptability and resilience to cyclical stresses, whereas rigidity demands structural stiffness and long-term stability.

Key Engineering Challenges and Solutions

Deployable structures face challenges in achieving reliable folding mechanisms and seamless deployment while maintaining lightweight characteristics and structural integrity, often addressed through advanced materials like shape-memory alloys and innovative kinematic design. Rigid structures require solutions to enhance load-bearing capacity and resistance to deformation under dynamic forces, typically utilizing high-strength composites and optimized geometric configurations. Both structures benefit from computational modeling and simulation techniques to predict behavior and optimize performance under operational conditions.

Mass and Volume Efficiency Comparisons

Deployable structures offer superior mass and volume efficiency compared to rigid structures by folding or collapsing into compact configurations for transport and expanding during deployment, minimizing storage space and launch weight. Rigid structures maintain constant mass and volume regardless of deployment, often resulting in increased payload capacity requirements and higher transportation costs. The lightweight materials and innovative folding mechanisms in deployable systems optimize both structural integrity and space utilization, enhancing overall mission efficiency.

Deployment Mechanisms and Technologies

Deployable structures utilize advanced mechanisms such as scissor-like linkages, telescoping beams, and origami-inspired folding patterns to enable compact storage and rapid expansion, optimizing space efficiency and transportability in aerospace and emergency shelters. Rigid structures rely on fixed joints and solid materials like steel or concrete, providing stability and load-bearing capacity but requiring more extensive construction and assembly processes. Innovations in smart materials and shape-memory alloys are enhancing deployable technologies, enabling autonomous unfolding and reconfiguration without manual intervention.

Structural Performance and Reliability

Deployable structures offer enhanced adaptability and compactness, enabling efficient transportation and rapid deployment, which improves structural performance in dynamic environments. Rigid structures provide superior load-bearing capacity and long-term stability due to their fixed geometry, ensuring high reliability under consistent stress conditions. Structural performance in deployable systems depends on material flexibility and joint mechanisms, whereas rigid structures rely on robust connections and stiffness for maintaining reliability.

Aerospace Applications: Use Cases and Trends

Deployable structures in aerospace offer compact storage and rapid expansion, critical for satellite antennas and solar arrays, enhancing payload efficiency and mission flexibility. Rigid structures provide robust stability and durability for primary airframes and launch vehicle components, ensuring structural integrity under extreme aerodynamic and mechanical loads. Emerging trends emphasize hybrid systems combining deployable mechanisms with rigid elements to optimize weight, performance, and adaptability in next-generation spacecraft design.

Future Prospects and Emerging Innovations

Deployable structures offer significant advancements with their lightweight materials and adaptive capabilities, enabling rapid assembly and reconfiguration in aerospace, architecture, and disaster relief applications. Emerging innovations include smart materials, such as shape-memory alloys and programmable polymers, enhancing responsiveness and durability in extreme environments. Rigid structures continue evolving through additive manufacturing and nanotechnology integration, improving load-bearing efficiency and sustainability, yet deployable systems are poised to dominate future designs due to their versatility and multifunctionality.

Morphing mechanisms

Deployable structures utilize morphing mechanisms for flexible, adaptive reconfiguration, whereas rigid structures rely on fixed geometries that lack dynamic shape transformation capabilities.

Stowage efficiency

Deployable structures offer superior stowage efficiency compared to rigid structures due to their ability to collapse into compact forms, maximizing space utilization during transport and storage.

Kinematic joints

Kinematic joints in deployable structures enable controlled movement and flexible reconfiguration, whereas rigid structures rely on fixed joints for stability and lack adaptability.

Shape memory alloys

Shape memory alloys enable deployable structures to transform and recover shapes efficiently, offering superior flexibility compared to traditional rigid structures.

Packaging ratio

Deployable structures achieve significantly higher packaging ratios than rigid structures by compactly folding for transport and expanding in use.

Hinged truss designs

Hinged truss designs in deployable structures offer enhanced flexibility and compact storage compared to rigid structures, enabling efficient load distribution and ease of assembly in dynamic architectural and engineering applications.

Inflatable composites

Inflatable composite deployable structures offer enhanced portability, rapid deployment, and lightweight flexibility compared to traditional rigid structures, making them ideal for aerospace and temporary architecture applications.

Self-deploying systems

Self-deploying systems in deployable structures offer adaptive functionality and lightweight design advantages over traditional rigid structures by enabling autonomous transformation and efficient space utilization.

Latch mechanisms

Latch mechanisms in deployable structures enable quick, secure connections and flexibility, contrasting with the permanent, fixed joints typical of rigid structures.

Structural reconfigurability

Deployable structures offer superior structural reconfigurability compared to rigid structures by enabling transformation in shape and size through modular, foldable, or telescoping components.

Deployable structures vs Rigid structures Infographic

njnir.com

njnir.com